Long-distance insulated power transmission bus

A long-distance, busbar technology, applied in the direction of transportation and packaging, containers to prevent mechanical damage, clamping devices, etc., can solve the problems of power transmission busbar surface damage, vehicle bumps, insulation performance effects, etc., to achieve protection integrity, prevent The effect of skin abrasion and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

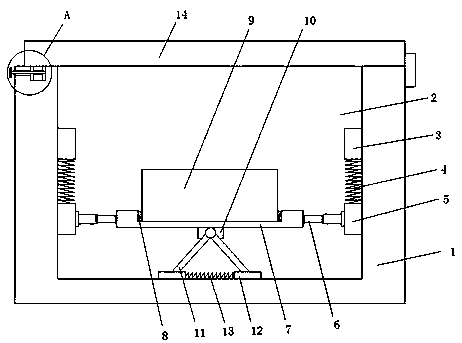

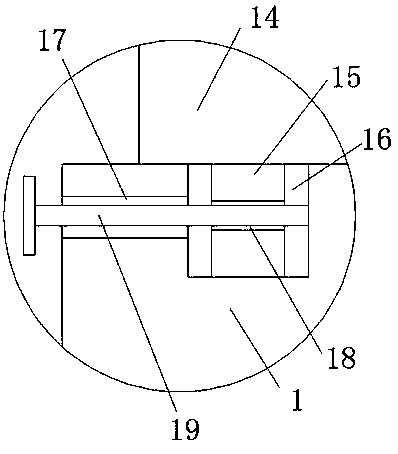

[0017] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

[0018] refer to Figure 1-2 , a long-distance insulated power transmission bus, comprising a protective box 1, the top of the protective box 1 is provided with a protective groove 2, the inner walls of both sides of the protective groove 2 are slidingly connected with a positioning plate 3, and the bottom of the positioning plate 3 is fixedly connected with a pull Stretching spring 4, the bottom of the stretching spring 4 is fixedly connected with a moving plate 5, one side of the moving plate 5 is slidingly connected with the side wall of the protective groove 2, and the sides of the two moving plates 5 close to each other are fixedly installed with buffer hydraulic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com