Ultra-thick plate cutting machine

A cutting machine and extra-thick plate technology, used in metal processing and other directions, can solve the problems of time-consuming and laborious, difficult to ensure cutting accuracy, and inability to cut plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Further description will be made below in conjunction with the accompanying drawings.

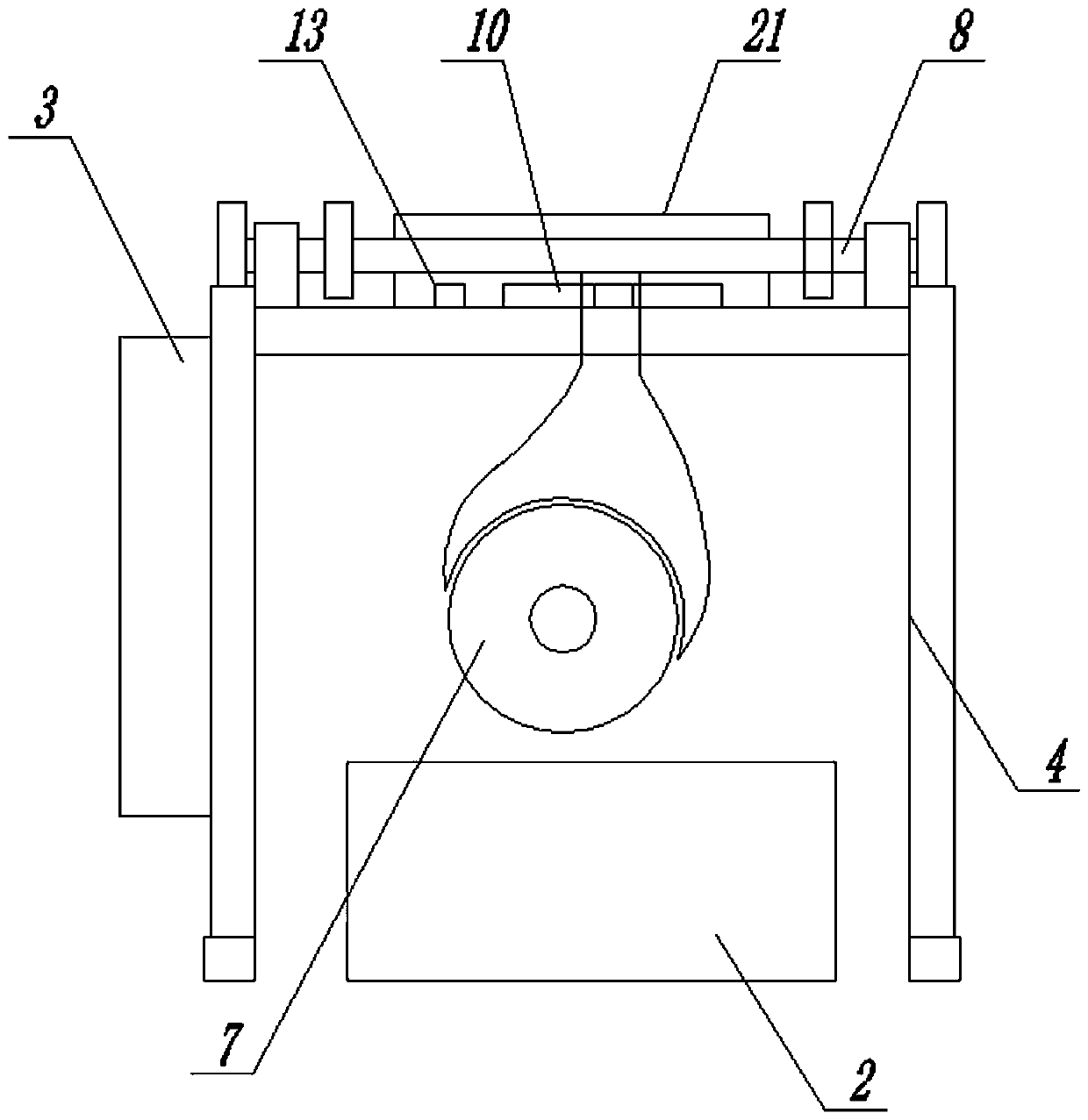

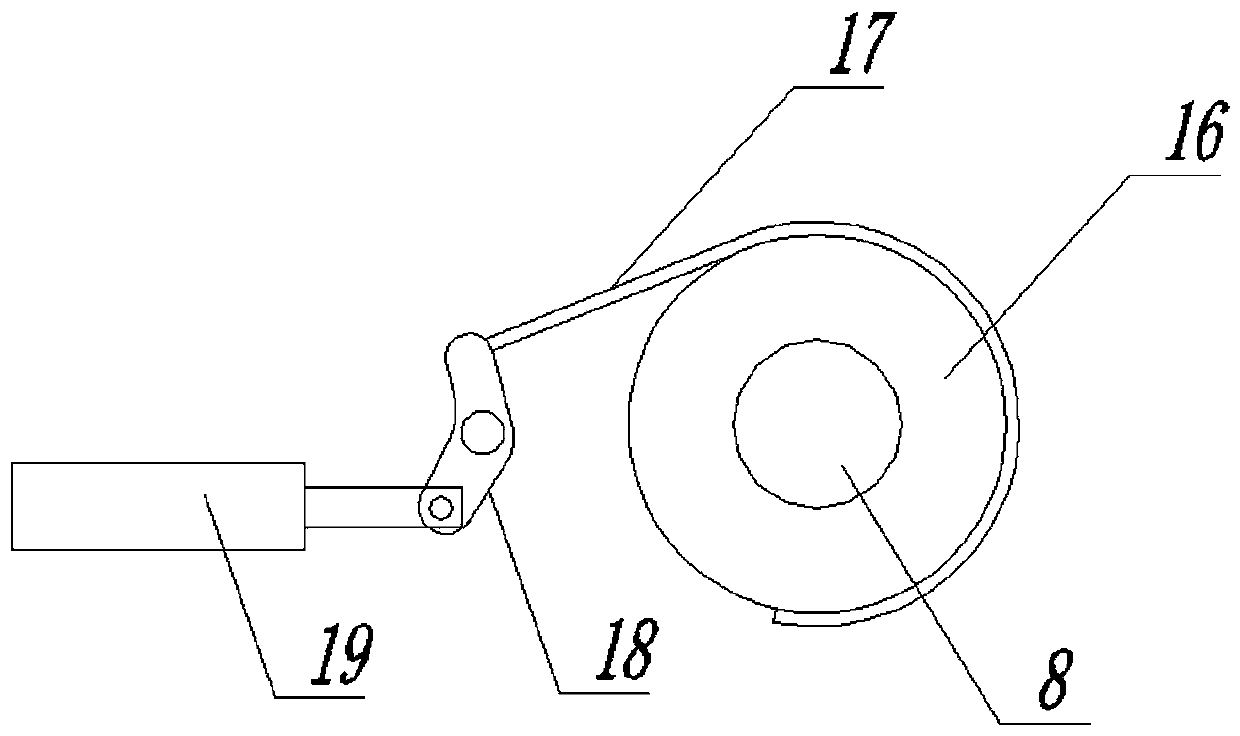

[0015] Figure 1-3 Shown: a special thick plate cutting machine includes a cutting track 1, a platform 2, a control box 3, a feed frame 4, a cutting seat 5, a rotating shaft 6, a saw blade machine 7, a supporting shaft 8, and a pulley group 9. Limit turntable 10, limit seat 11, limit block 12, horizontal limit bayonet 13, longitudinal limit bayonet 14, limit sensor 15, brake disc 16, brake belt 17, brake arm 18, brake cylinder 19 , limit probe 20, feed motor 21.

[0016] The platform 2 is set in two parallel cutting tracks 1, and the two ends of the feed frame 4 are supported on the cutting tracks by the rollers, and the motor on the feed frame drives the gear to mesh with the rack on the cutting track to drive the feed frame. Move on the cutting track to the state above the platform, the cutting track is provided with a limit probe 21 corresponding to the displacement of the two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com