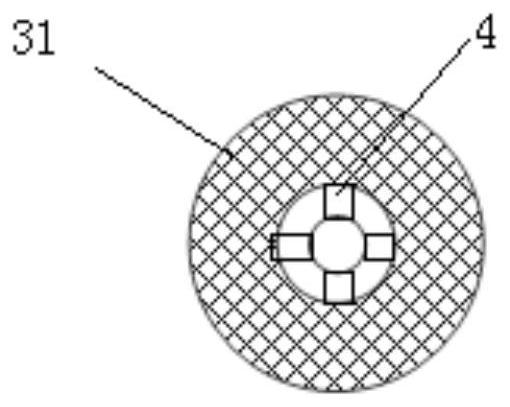

A porous ceramic tubular filter catalytic denitrification unit and its flue gas purification method

A technology of tubular filtration and catalytic denitrification, applied in chemical instruments and methods, separation methods, filtration and separation, etc., can solve the problems of increasing the burden of wastewater treatment, reduce the impact of erosion and poisoning, improve production capacity and heat utilization efficiency, The effect of improving the recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The present invention utilizes a small-scale flue gas purification device in a laboratory to carry out experimental research. The simulated alumina roasting flue gas is provided by calcining aluminum hydroxide and coal powder in a rotary kiln, and the flue gas volume is 100Nm 3 / h. After the flue gas at the outlet of the rotary kiln passes through the cooling device, it passes through two flue gas pipes and enters the separate porous ceramic tubular filter catalytic denitrification unit and SCR catalytic unit, and finally merges into a flue gas and then enters the subsequent flue gas deep evolution equipment . At the outlet of the cooling device downstream of the rotary kiln, a certain amount of heated ammonia is vaporized by a Venturi injection device and sprayed into the flue. The flue gas temperature is maintained at 400°C, and the NOx concentration is 400mg / Nm 3 , the dust concentration is 1g / Nm 3 , the filtration speed of the flue gas on the ceramic membrane is...

Embodiment 2

[0041] Utilize the same porous ceramic tubular filter catalytic denitrification unit as in Example 1 to carry out the experiment, the NOx concentration in the flue gas is 400mg / Nm 3 , spray a certain amount of vaporized ammonia water into the pipeline, and the ammonia / nitrogen ratio in the flue gas is about 0.8:1. After passing through the SCR reactor, the dust concentration in the flue gas is 0.7g / Nm 3 , NOx concentration is 140mg / Nm 3 , and the flue gas dust concentration after passing through the above-mentioned porous ceramic tubular filter catalytic denitrification unit of the present invention is 0.05g / Nm 3 , NOx concentration is 100mg / Nm 3 . It can be seen that the purification effect is far better than that of the SCR reactor.

Embodiment 3

[0043] Utilize the same porous ceramic tubular filter catalytic denitrification unit as in Example 1 to carry out the experiment, the NOx concentration in the flue gas is 400mg / Nm 3 , spray a certain amount of vaporized ammonia water into the pipeline, and the ammonia / nitrogen ratio in the flue gas is about 1:1. After passing through the SCR reactor, the dust concentration in the flue gas is 0.7g / Nm 3 , NOx concentration is about 110mg / Nm 3 , and the concentration of flue gas dust passing through the porous ceramic tubular filter catalytic denitrification unit of the present invention is 0.05g / Nm 3 , NOx concentration is about 70mg / Nm 3 . It can be seen that the purification effect is far better than that of the SCR reactor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com