Rumen bypass protecting amylase and preparation method thereof

A amylase and rumen-passing technology, which is applied in the field of rumen-passing amylase and its preparation, can solve the problems of ineffective production performance of ruminants, etc., and achieve the goals of improving conception rate during estrus, good coating effect, and preventing ketosis Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

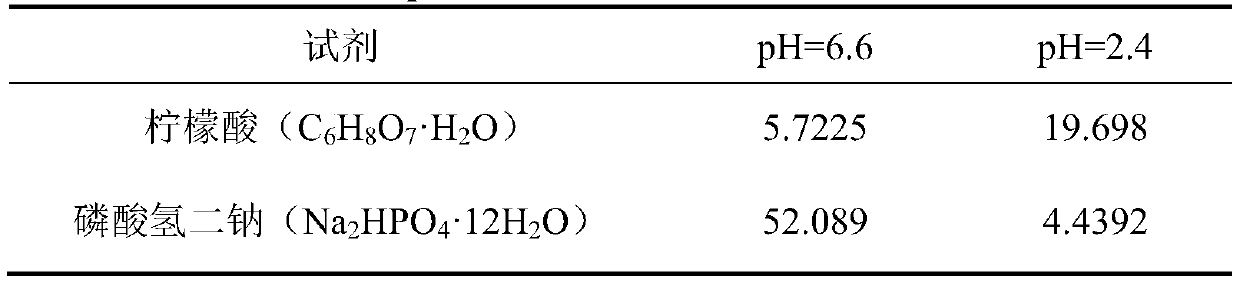

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1: the preparation method of the rumen amylase of 100 units / g

[0039] Weigh 120 grams of 2000 units / g of α-amylase, add to 880 grams of lysine powder and mix, dry granulate in a dry granulator, dry at 70°C at low temperature to obtain dried granules; put 1000 100 grams of palm oil fat powder is heated to 100°C and melted as a packaging material; the dried granules containing amylase are fluidized in a fluidized bed, and the melted packaging material is cooled to 80°C and sprayed on the granules containing amylase On the surface, 100 units / g of ruminal amylase was obtained.

Embodiment 2

[0040] Embodiment 2: the preparation method of the rumen amylase of 400 units / g

[0041] Weigh 480 grams of 2000 units / g of α-amylase, add to 520 grams of lysine powder and mix, dry granulate in a dry granulator, dry at 70°C at low temperature to obtain dried granules; put 1000 100 grams of palm oil fat powder is heated to 100°C and melted as a packaging material; the dried granules containing amylase are fluidized in a fluidized bed, and the melted packaging material is cooled to 80°C and sprayed on the granules containing amylase On the surface, 400 units / g of rumen amylase was obtained.

Embodiment 3

[0042] Embodiment 3: the preparation method of the rumen amylase of 2000 units / g

[0043] Weigh 600 grams of 8000 units / g of α-amylase, add to 400 grams of lysine powder and mix, dry granulate in a dry granulator, and dry at 70°C at low temperature to obtain dried granules; The palm oil fat powder is heated to 100°C and melted as a packaging material; the dried granules containing amylase are fluidized in a fluidized bed, and the molten packaging material is cooled to 80°C and sprayed on the surface of the amylase-containing granules , that is, to obtain 2000 units / g of rumen-passing amylase.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com