Transformer respirator and regeneration method of silica gel in respirator

A respirator and transformer technology, applied in the direction of transformer/inductor cooling, etc., can solve the problems of high labor cost, potential safety hazards, time-consuming and labor-intensive disassembly and assembly workers, etc., to improve labor productivity, reduce human errors, and save disassembly and assembly. The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

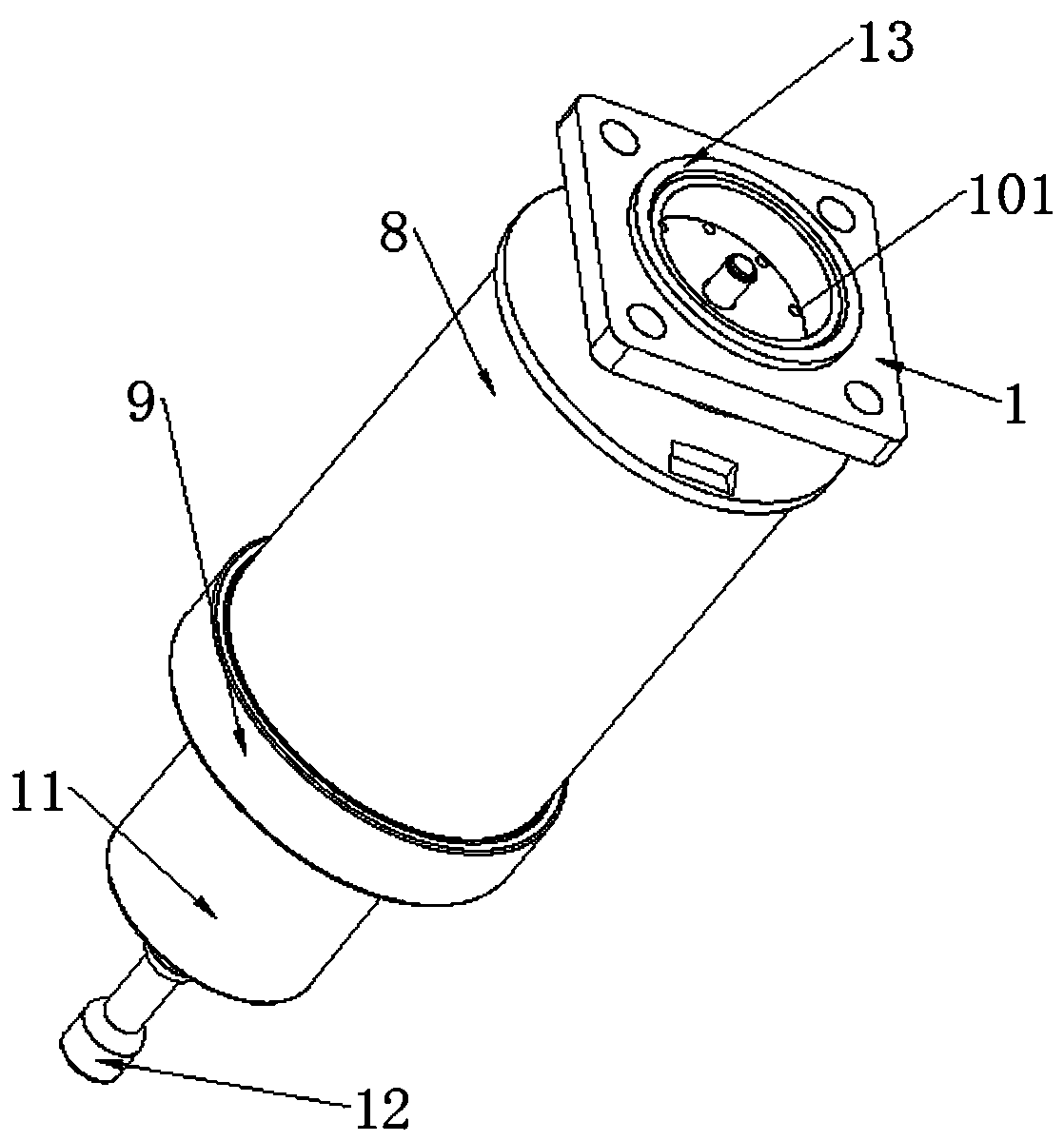

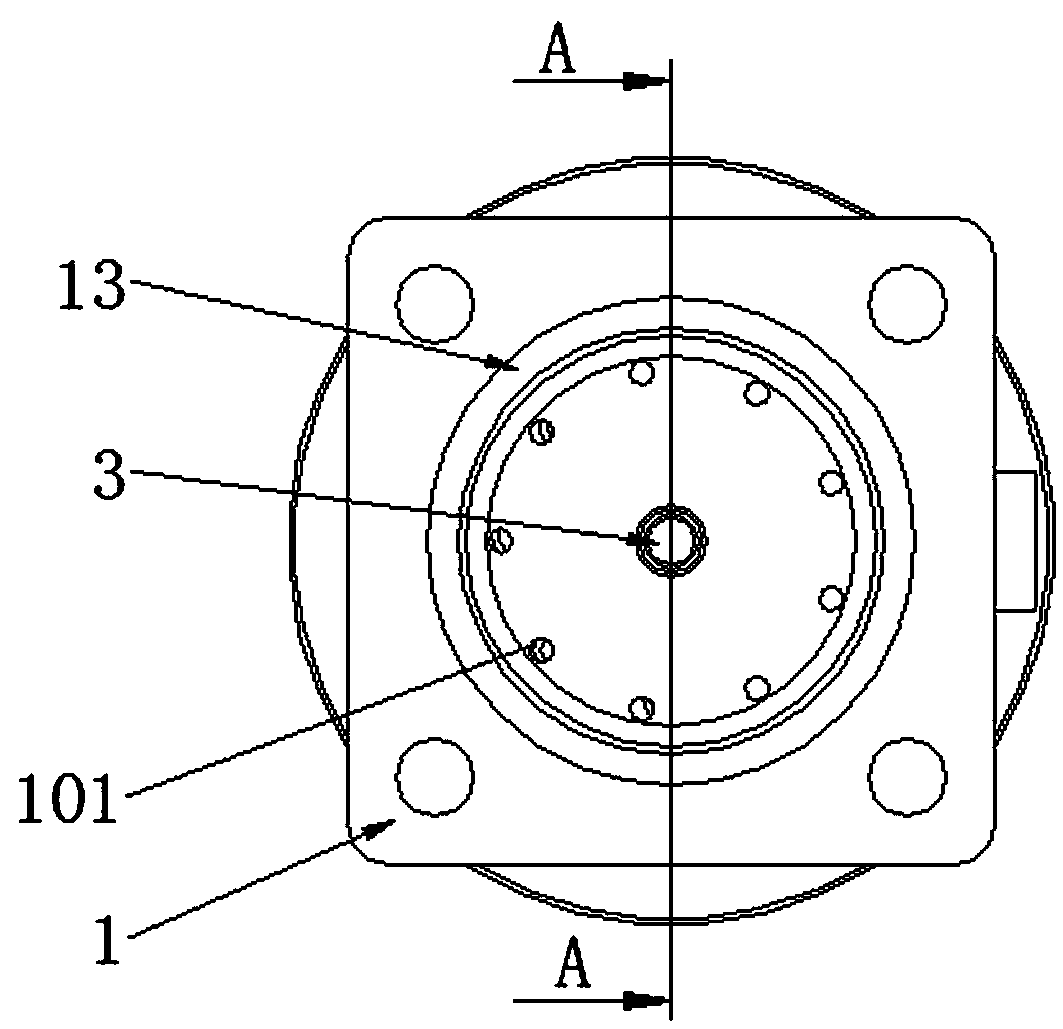

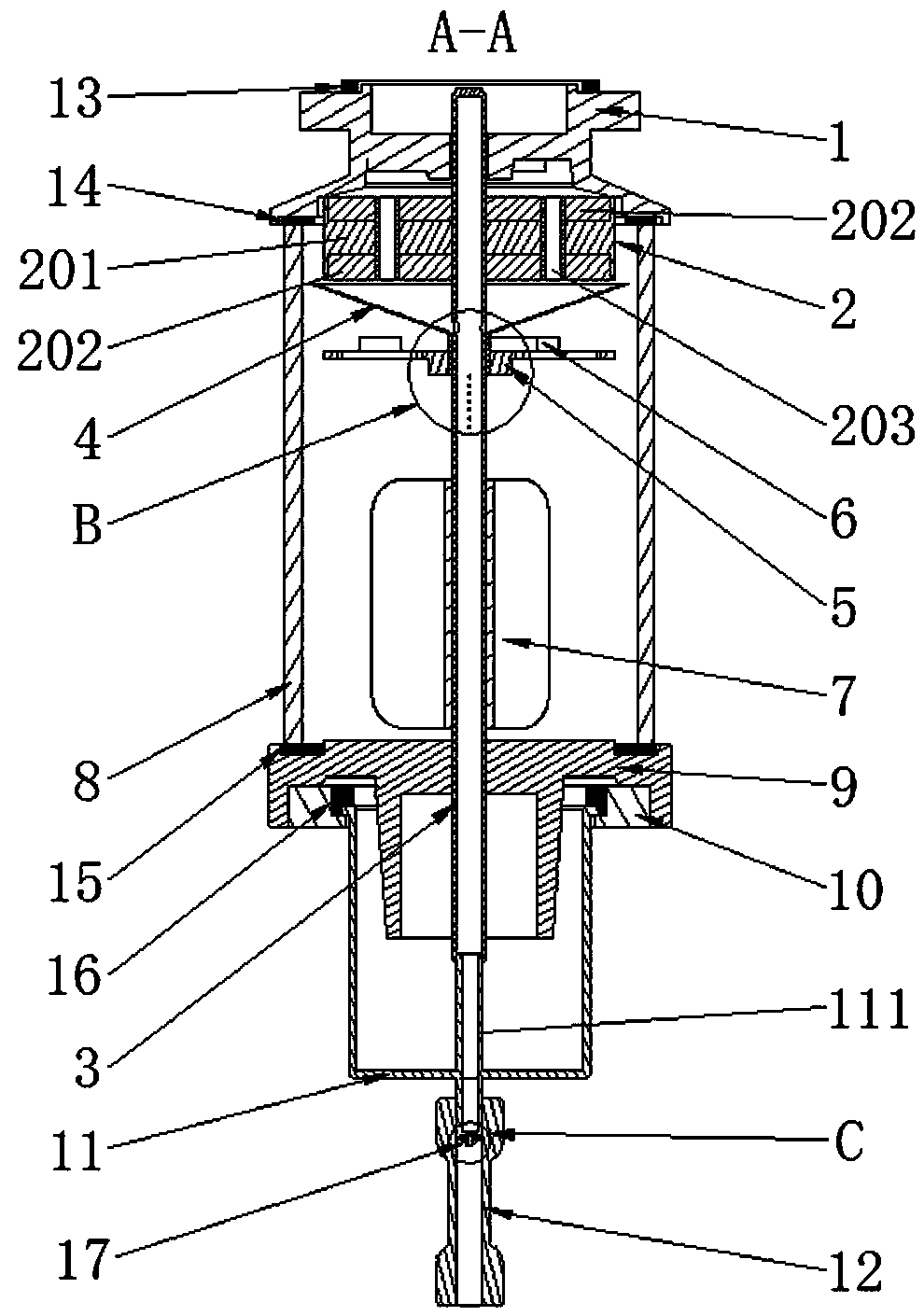

[0042] see Figure 1-11 , a transformer respirator, comprising a silica gel bottle 8, an upper cover 1 fixed to the upper end of the silica gel bottle 8 for connecting an oil conservator, a lower cover 9 fixed to the lower end of the silica gel bottle 8, and a lower cover fixed to the lower cover 9 below the oil seal cup 11; the upper cover 1 is provided with a number of vent holes 101 vertically connected to the oil conservator and the silicone bottle 8, and the vent holes 101 are used for the ventilation ducts of the silica gel bottle 8 and the oil conservator Connected; the lower cover 9 is provided with a number of vertical through oil holes 901 communicating with the oil seal cup 11; the middle part of the silicone bottle 8 is vertically provided with a hollow breathing tube 3, and the upper end of the breathing tube 3 Go out upwards an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com