Overhead line discharge breakdown fault monitoring apparatus and method

An overhead line and discharge breakdown technology, which is applied in the direction of fault location, fault detection according to conductor type, and dielectric strength test, can solve problems such as unstable operation, high cost, and false alarms of fault monitoring devices, and reduce fault finding Difficulty, the effect of saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

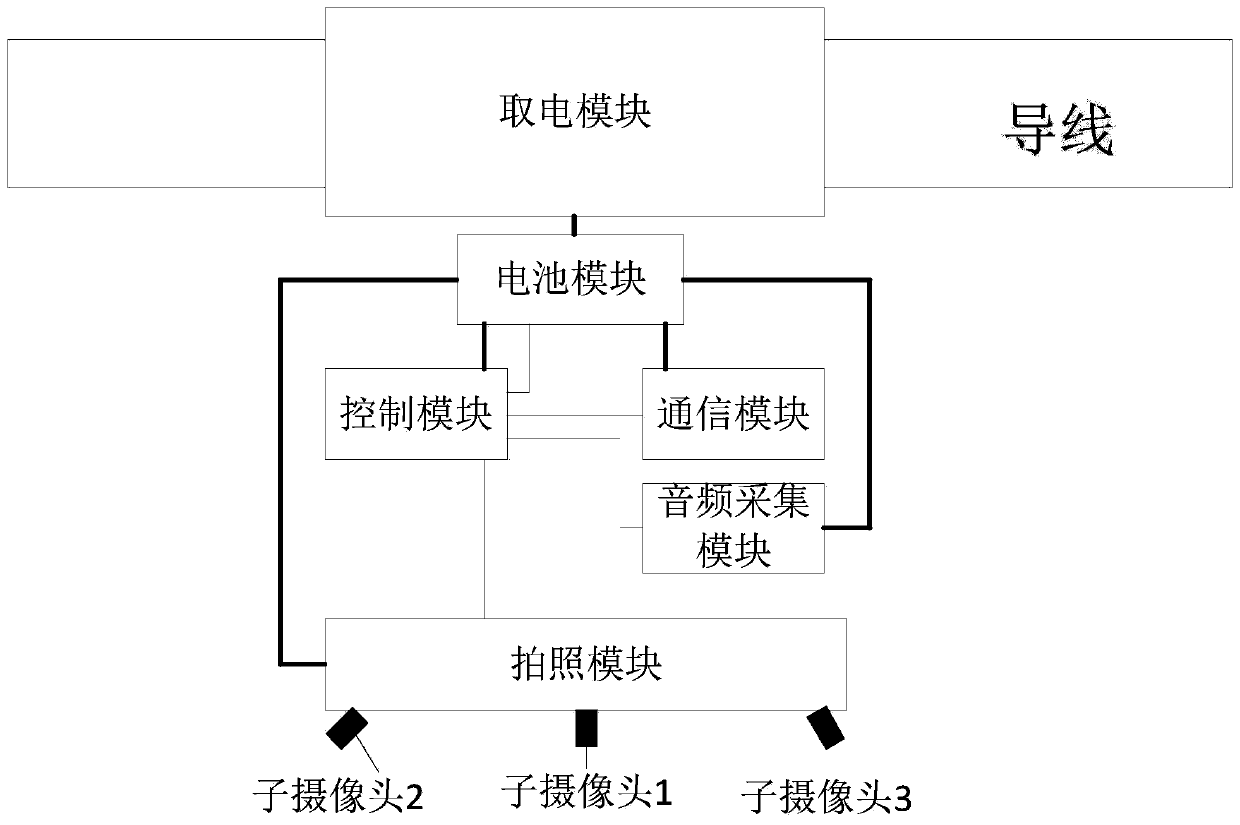

[0021] see figure 1 , this embodiment includes a power-taking module, a battery module, a control module, an audio collection module, a camera module and a communication module. The power-taking module is installed on the overhead line, and takes power from the overhead line to charge the battery module. The battery module supplies power to other modules except the power-taking module. The control module monitors the charging connection status between the power-taking module and the battery module. The acquisition module collects the ambient sound and sends it to the control module to determine the volume of the ambient sound. The camera module communicates with the control module and takes pictures under the control of the control module and transmits them to the control module. The communication module receives the information that needs to be sent provided by the control module and sent to the remote control center. The power-taking module continues to charge the battery m...

Embodiment 2

[0024] The device of this embodiment is basically the same as that of Embodiment 1, except for the camera module. The photographing module of this embodiment adopts a rotating camera. When it is necessary to take pictures, the rotating camera rotates from one side to the other, and the images taken during the rotation are synthesized into a seamless panorama photo, which can be combined with The shooting of the panorama photo is completed as in Embodiment 1.

[0025] When using the above-mentioned device to monitor the discharge breakdown fault of the overhead line, the following steps are included:

[0026] Step 1, real-time acquisition of overhead line power transmission conditions and ambient volume conditions at the monitoring location;

[0027] Step 2, when the power transmission of the overhead line is interrupted and the ambient volume reaches the preset volume decibel value, a warning message is sent to the control center;

[0028] Step 3: collect the image of the mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com