Method and device for detecting output gas flow of gas storage tank

A gas flow and gas storage tank technology, which is applied in the method of container discharge, volume/mass flow generated by mechanical effect, container filling method, etc. Portability and other issues can reduce the occupied space and weight, improve the accuracy of flow detection, and reduce manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

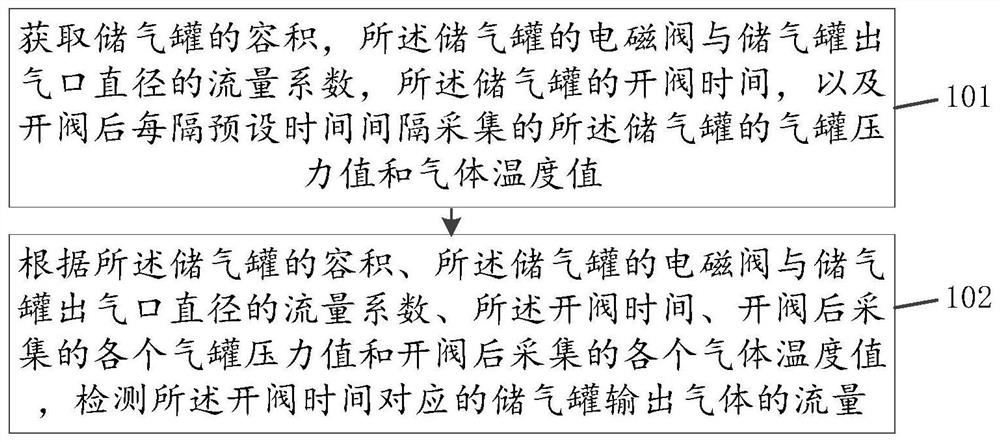

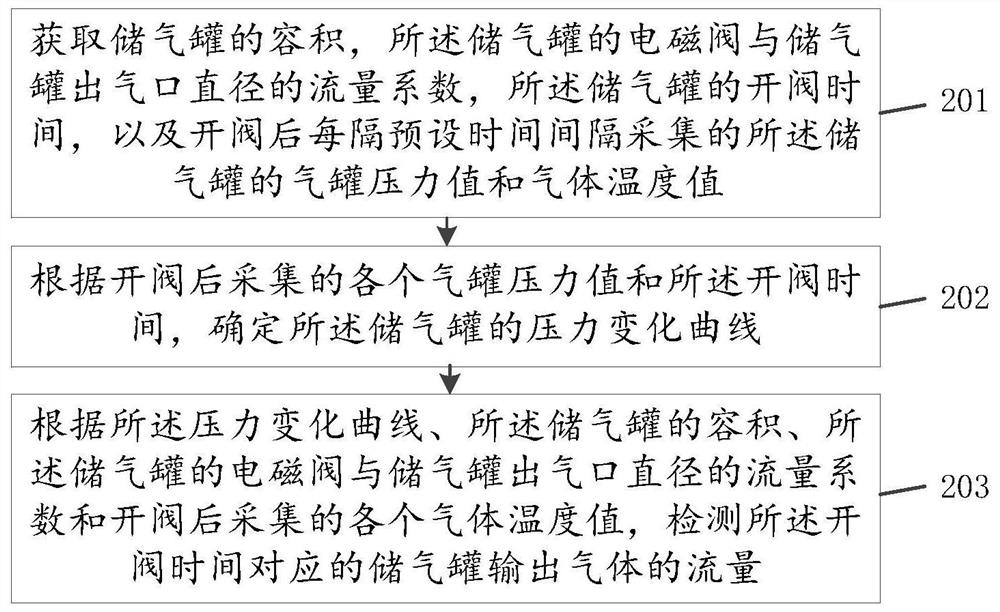

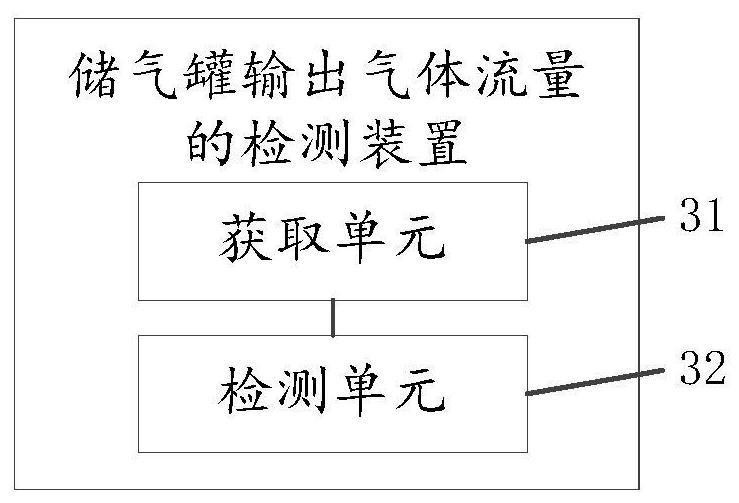

Method used

Image

Examples

Embodiment Construction

[0025] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other.

[0026] As the background technology, at present, there are usually two ways to detect the output gas flow rate of a gas storage tank such as an oxygen generator, one is to detect the gas flow rate through a flow sensor, and the other is to use a combination of a pressure sensor and a spring. However, using a flow sensor to detect the gas flow will increase the manufacturing cost of the gas storage tank. In addition, using a combination of sensors and springs to detect the gas flow will cause the spring to be installed in the gas storage tank. The components of the gas storage tank are added, resulting in a complicated internal structure of the gas storage tank, which takes up more space and is not ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com