"8" hole sealing device and method for gear pump test

A technology for testing and gear pumps, which is applied in the direction of measuring devices, engine sealing, and applying stable tension/pressure to test the strength of materials. To avoid problems such as large force, to achieve the effects of avoiding shell damage, reducing sealing area, high stability and adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below.

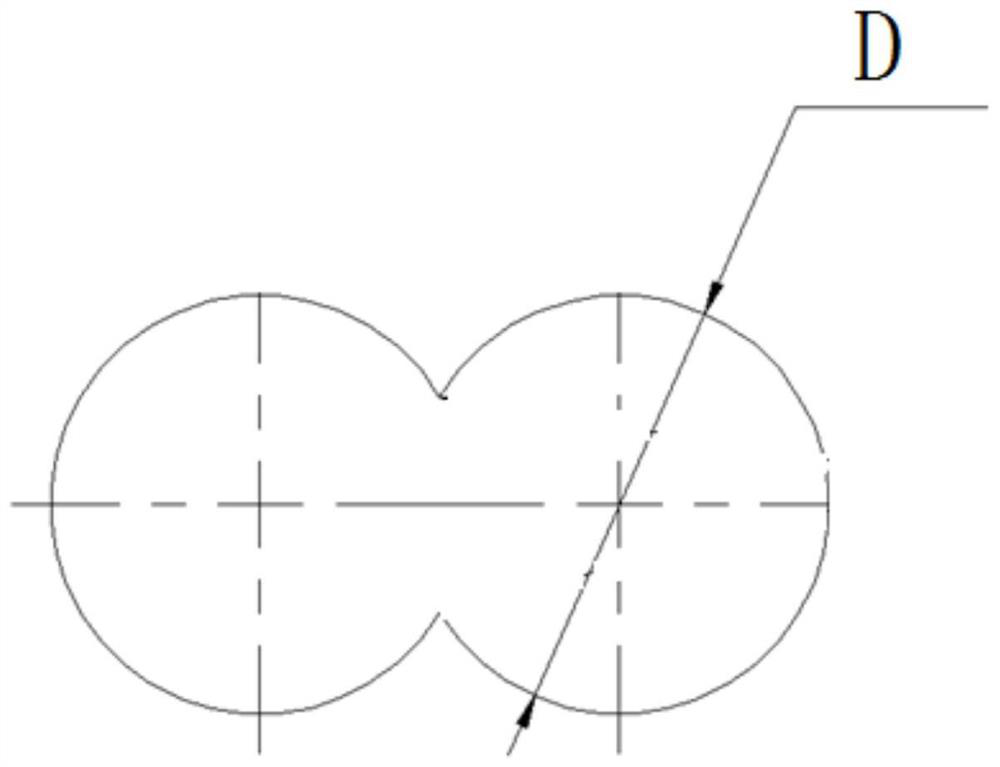

[0038] see figure 1 , The "8" type hole has two intersecting circles from its cross-section.

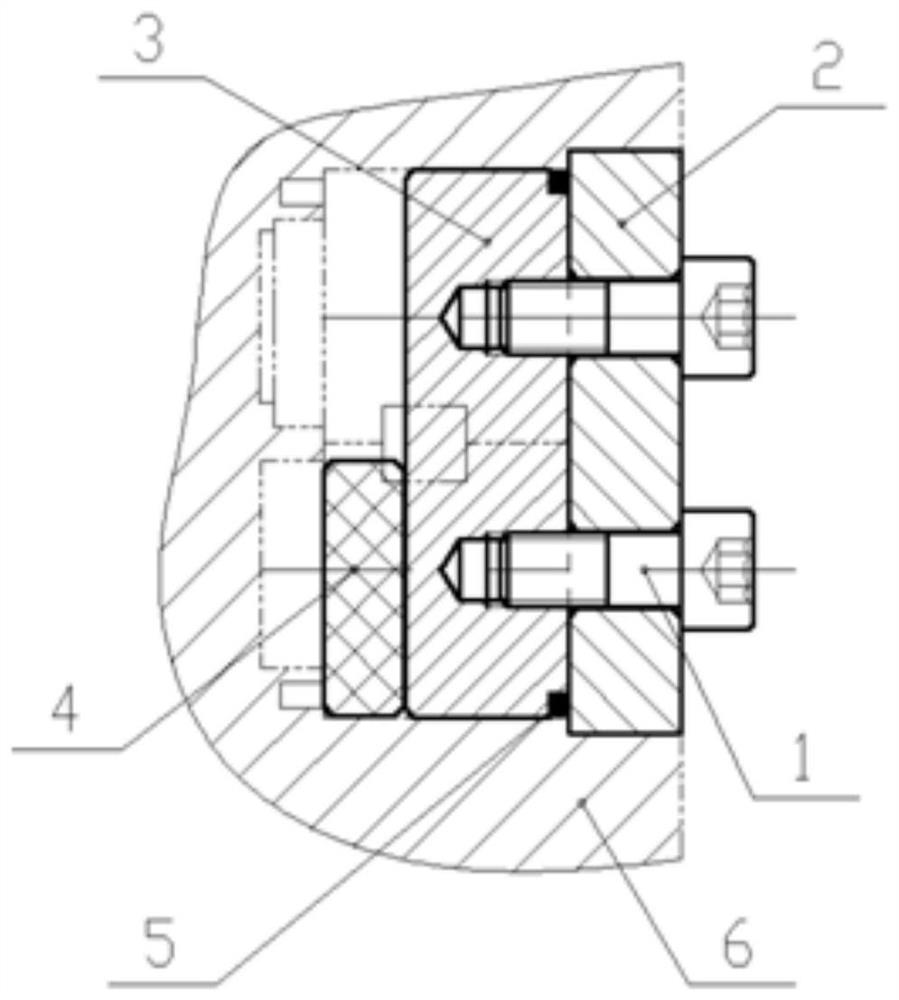

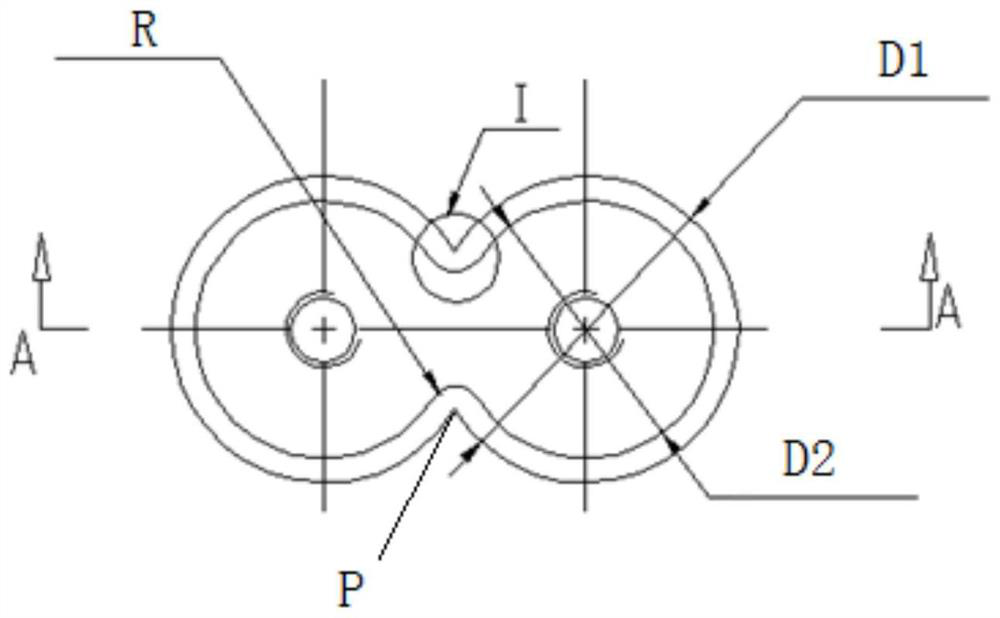

[0039] see figure 2 The "8" hole of the housing 6 is sealed by the "8" hole sealing device, the "8" hole sealing device includes a screw 1, a bottom plate 2, an "8" type plug 3, a pad 4, and a sealing Circle 5. Wherein, a spacer 4 is placed at the bottom of the "8"-shaped hole, and the "8"-shaped plug 3 is put into the "8"-shaped hole. see Figure 3-4 There is a sealing groove with a stepped structure on the edge of the outer end face of the "8" type plug 3, and a sealing ring 5 with a matching shape is placed in the sealing groove, and the bottom plate 2 covers the "8" type plug 3, and a combined seal is formed after tightening the screw 1 .

[0040] Wherein, choosing a spacer 4 with an appropriate height can ensure the installation height of the "8" type plug 3 .

[0041] For an "8" type hole, in orde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com