Novel submersible slag slurry pump

A slurry pump, a new type of technology, applied in the direction of pumps, pump devices, pump components, etc., can solve the problems of low mesh density of the protective cover, low water pressure of the slurry pump, easy blockage of the slurry pump, etc. Larger, faster pumping speed, better pressure-holding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

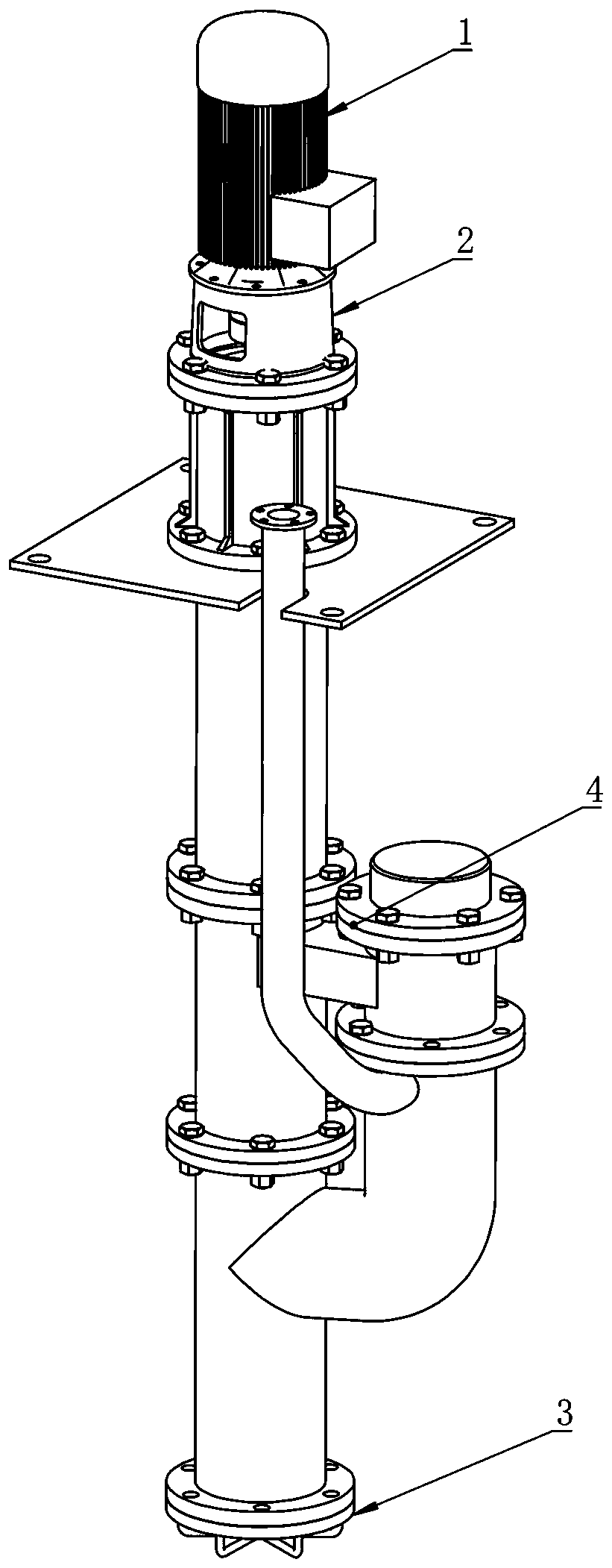

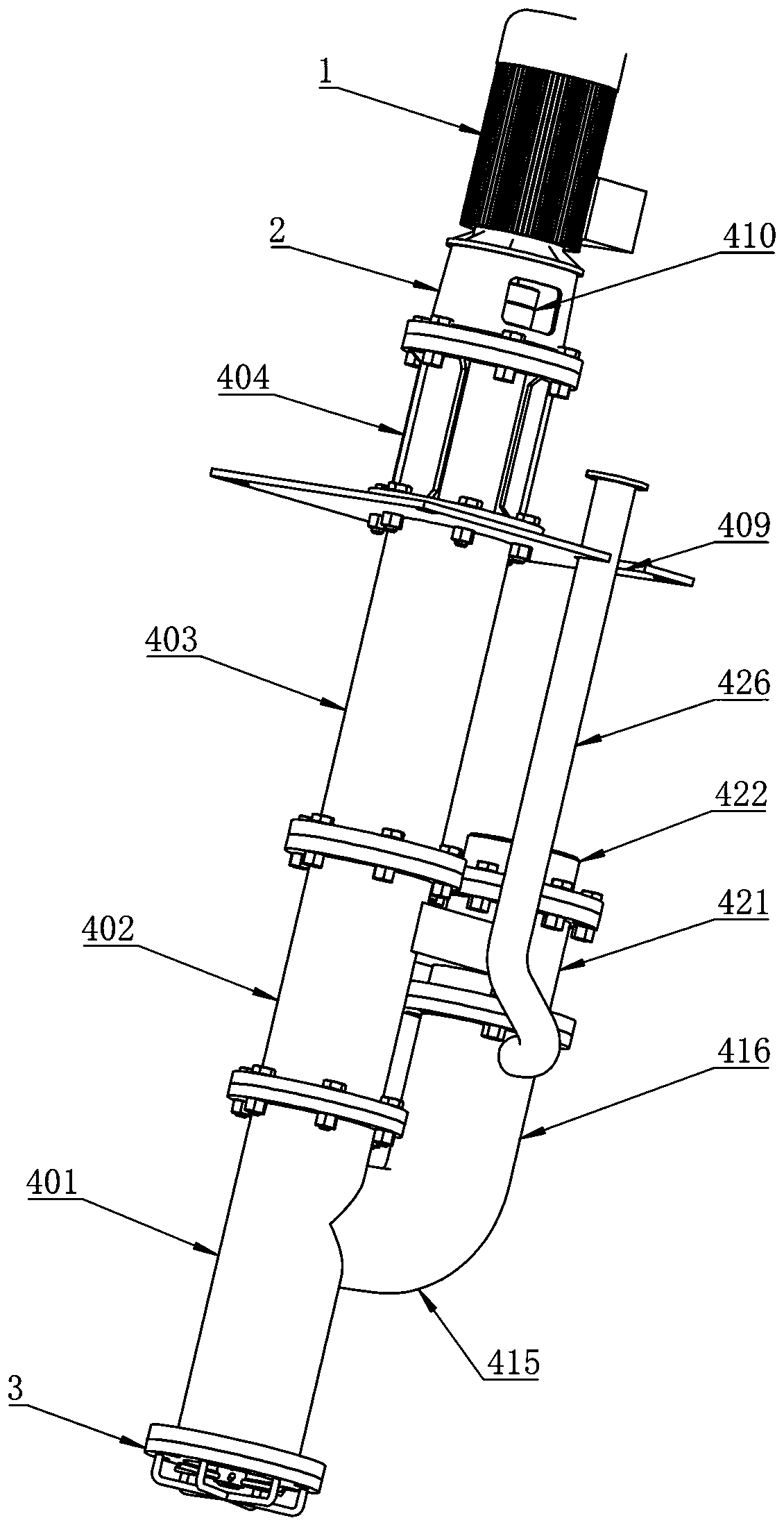

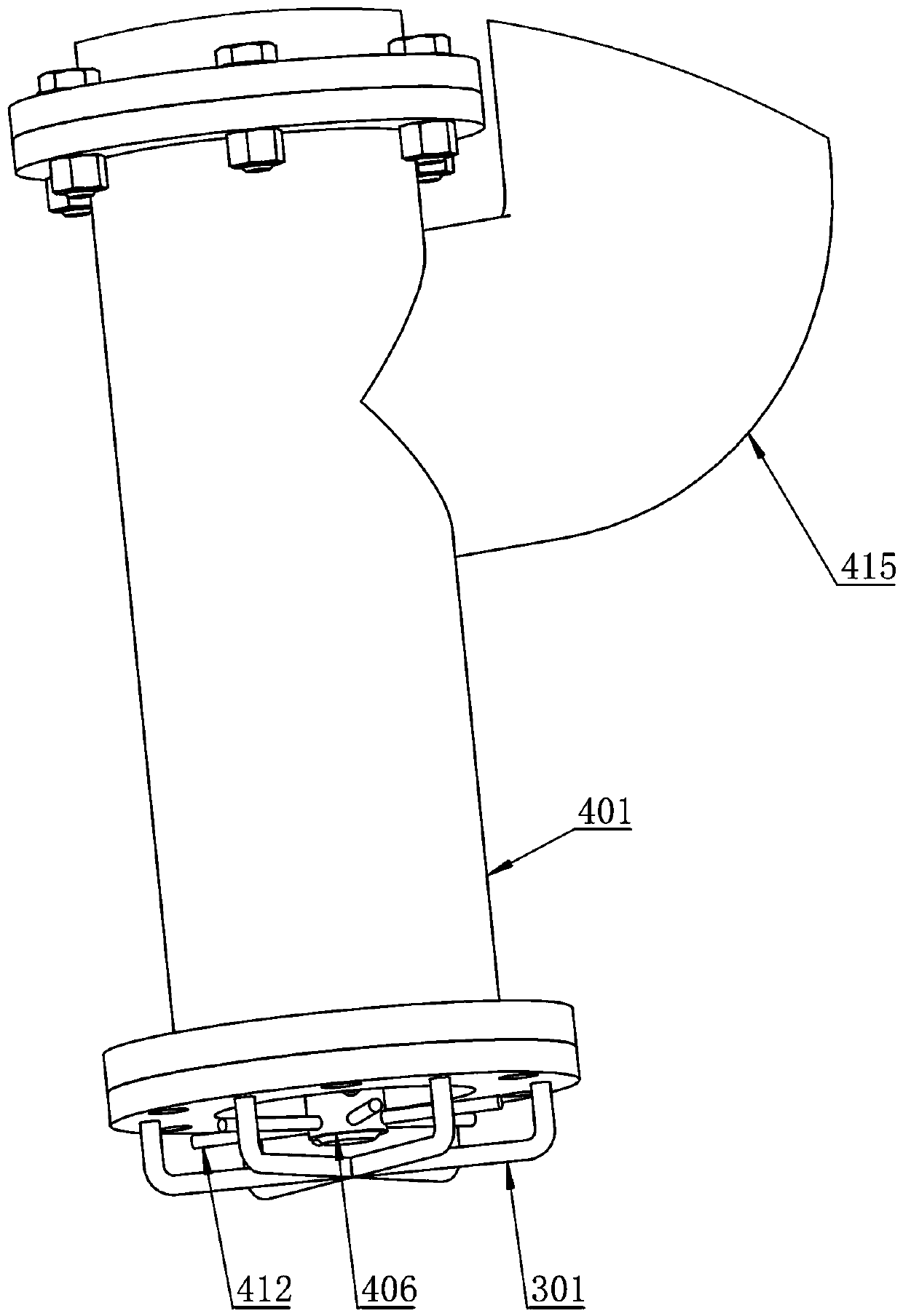

[0039] Specific implementation mode one: combine Figure 1-7As shown, a new type of submersible slurry pump is characterized in that: it includes a motor 1, a bell 2, a protective cover 3 and a pressurized anti-blocking pumping device 4; The top of the pumping device 4; the protective cover 3 is fixedly arranged at the bottom of the pressurized and anti-blocking pumping device 4; the pressurized and anti-blocking pumping device 4 includes a pumping main pipe 401, an active driving pipe 402, and a space support Pipe 403, connecting pipe 404, mechanical seal assembly 405, main shaft 406, transmission shaft 407 and belt 408; the active drive pipe 402 is fixedly connected to the top of the pump liquid main pipe 401 by flange; the spaced support pipe 403 is fixedly connected by flange At the top of the active drive tube 402; the flange of the connecting tube 404 is fixed on the top of the spaced support tube 403; the top of the connecting tube 404 and the motor 1 are fixed by the b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com