Leakage prevention and stoppage tool for loess layer and using method of leakage prevention and stoppage tool

A loess layer and tool technology, which is applied in earth-moving drilling, wellbore/well components, sealing/packing, etc., can solve problems such as affecting drilling time efficiency, environmental pollution, etc., to solve drilling annulus leakage, avoid environmental pollution, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

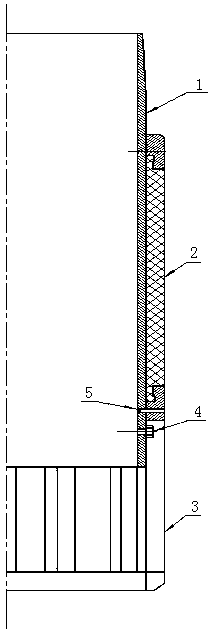

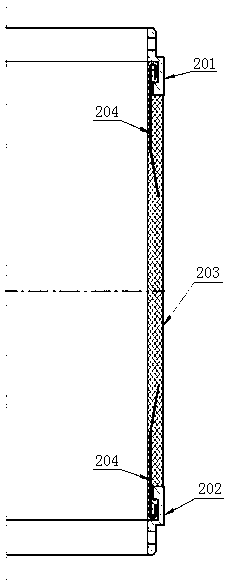

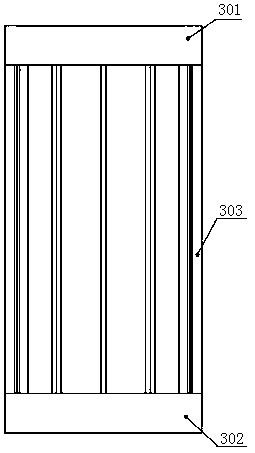

[0032] The first embodiment of the present invention relates to a loess layer leak prevention and plugging tool, as shown in Figure 1, at least including a pipe body 1 and a rubber sleeve assembly 2, a sliding Cover 3, as shown in Figure 2, the rubber cartridge assembly 2 at least includes a rubber cartridge 203, the two ends of the rubber cartridge 203 are respectively provided with an upper steel ring 201 and a lower steel ring 202, and the upper steel ring 201 is fixed On the upper part of the pipe body 1, the lower steel ring 202 is fixed on the lower part of the pipe body 1, and the lower steel ring 202 and the pipe body 1 are positioned by the shear pin 5; the sliding sleeve 3 can slide upward along the pipe body 1, After pushing the lower steel ring 202 to cut off the shear pin 5, continue to slide upward under pressure and squeeze the rubber tube 203, so that the rubber tube 203 is compressed in the axial direction, expanded in the radial direction, and contacts with th...

no. 2 approach

[0036] This embodiment relates to a leak-proof and plugging tool for loess layers, which includes a pipe body 1, and a rubber sleeve assembly 2 and a sliding sleeve 3 that are sequentially sleeved on the pipe body 1 from top to bottom, such as figure 2 As shown, the rubber cartridge assembly 2 includes an upper steel ring 201, a lower steel ring 202, a rubber cartridge 203 and a spring leaf 204, and the upper steel ring 201 and the lower steel ring 202 are respectively arranged on the upper and lower sides of the rubber cartridge 203. Both ends, and the upper steel ring 201 and the pipe body 1 are fixed with bolts, the lower steel ring 202 and the pipe body 1 are positioned by the shear pin 5, and the lower steel ring 202 and the sliding sleeve 3 are in gapless contact. The sliding sleeve 3 can slide upward along the pipe body 1, push the lower steel ring 202 to cut the shear pin 5, and then continue to slide upward under the action of pressure to form enough pressure on the r...

no. 3 approach

[0043] This embodiment provides a loess layer leak prevention and plugging tool, such as figure 1 As shown, it includes a pipe body 1 and a rubber sleeve assembly 2 and a sliding sleeve 3 that are sequentially sleeved on the pipe body 1 from top to bottom. The pipe body 1 is also provided with a limit bolt 4, such as figure 2 As shown, the rubber cartridge assembly 2 includes an upper steel ring 201, a lower steel ring 202, a rubber cartridge 203 and a spring leaf 204, and the upper steel ring 201 and the lower steel ring 202 are respectively arranged on the upper and lower sides of the rubber cartridge 203. Both ends, and the upper steel ring 201 and the pipe body 1 are fixed with bolts, the shear pin 5 is set between the lower steel ring 202 and the pipe body 1, and there is no gap between the lower steel ring 202 and the sliding sleeve 3 , the sliding sleeve 3 can slide up and down along the pipe body 1, and the sliding sleeve 3 is limited by the stop bolt 4 when it goes d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com