Red kojic rice beer and preparation method thereof

A technology for red yeast rice and beer, applied in the field of red yeast rice beer and its preparation, can solve the problems of affecting the non-biological stability of beer, obvious thick and heavy taste of beer, affecting the coordination of taste, etc., so as to reduce the risk of infection and reduce the Residual wine body, the effect of improving the harmony of the taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] (1) a kind of red yeast rice beer mainly is made up of dry material and water, and each component is by weight percentage in described dry material:

[0037] Australian barley malt 30kg, Canadian barley malt 30kg, Munich malt 10kg, red yeast rice 30kg.

[0038] (2) the preparation method of above-mentioned red yeast rice beer, comprises the following steps

[0039] S1. Pulverization: the red yeast rice is pulverized with a flour mill, sieved with a 0.45mm grading sieve, and the sieved material is greater than 70%; the malt is mixed to obtain the total malt, and the total malt is pulverized by a double-roll pulverizer. Preferably, before the crushing of the total malt, first add 10% of the total malt weight of warm water at 40-50°C to the mixed total malt, mix and place it for 10 minutes, and then start crushing. It is required that the bark of the total malt is not broken broken.

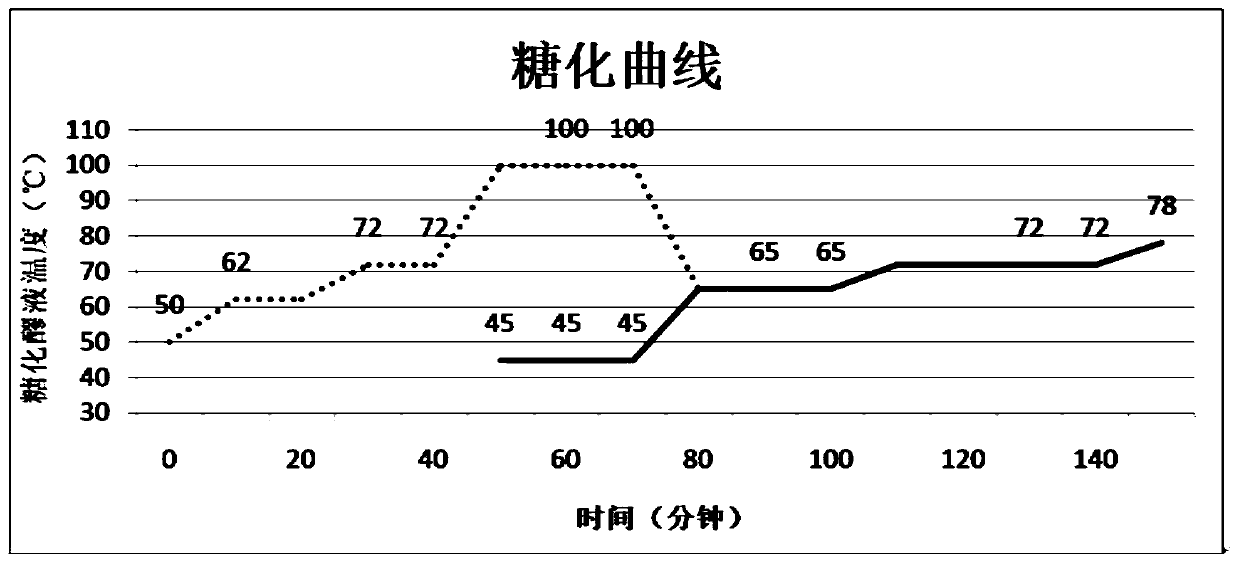

[0040] S2. Gelatinization process: mix red yeast rice with 10% total malt, mix with wat...

Embodiment 2

[0047] (1) a kind of red yeast rice beer mainly is made up of dry material and water, and each component is by weight percentage in described dry material:

[0048] 30kg of Australian barley malt, 30kg of Canadian barley malt, 9kg of crystallized malt, and 31kg of red yeast rice.

[0049] (2) The preparation method is the same as in Example 1.

Embodiment 3

[0051] (1) a kind of red yeast rice beer mainly is made up of dry material and water, and each component is by weight percentage in described dry material:

[0052] Australian barley malt 30kg, Canadian barley malt 30kg, caramel malt 8kg, red yeast rice 32kg.

[0053] (2) The preparation method is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com