Water-based extraction method for taraxacum rubber

A technology of dandelion rubber and extraction method, which is applied in the field of rubber, can solve the problems of high cost of solvent, etc., and achieve the effect of low price, simple method and high cost problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Region: Xinjiang

[0041] (1) The dried root of dandelion rubber grass is cleaned and dried at room temperature;

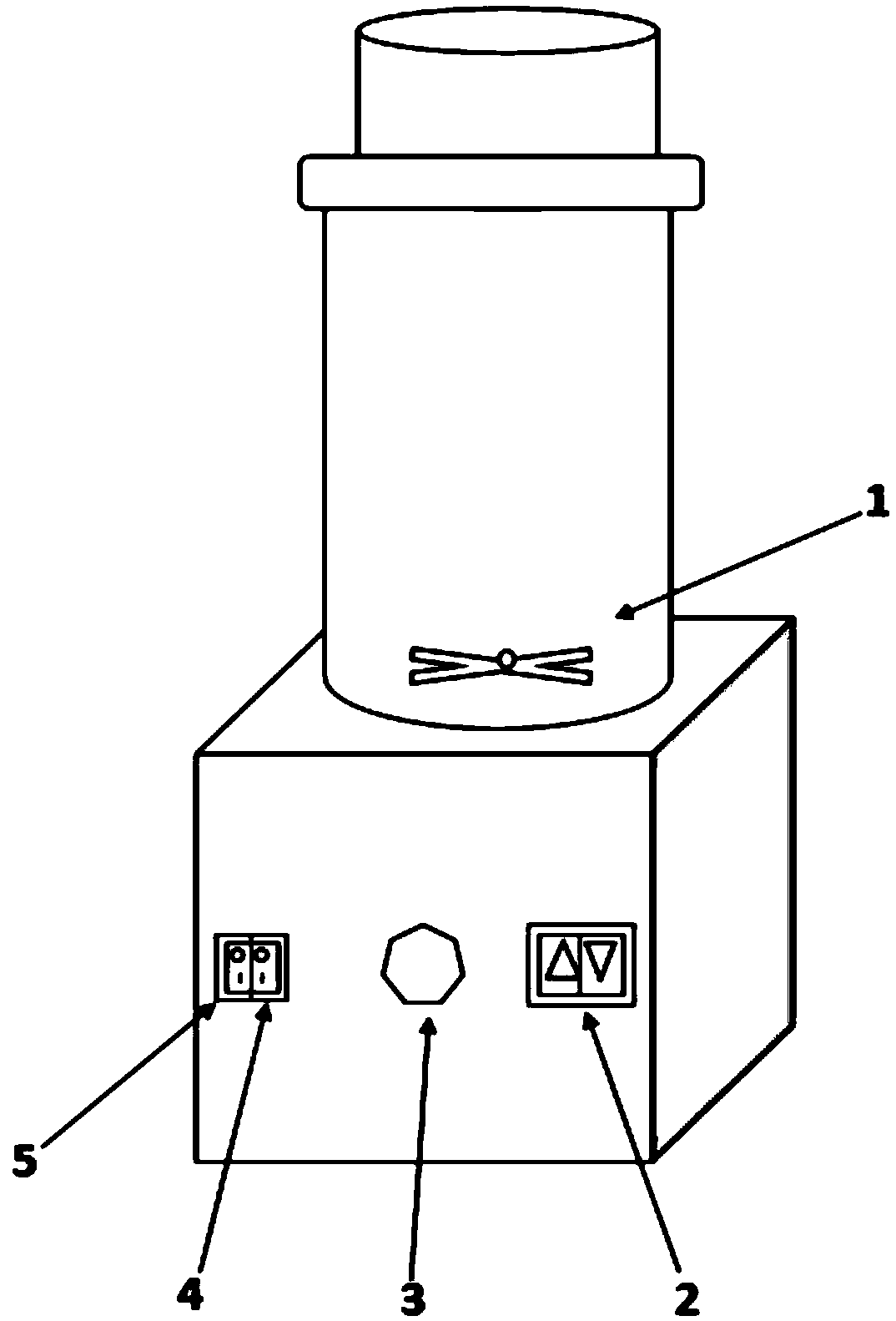

[0042] (2) The dried dandelion roots are loosened by a rolling machine to separate the glue filaments from the surrounding tissues, and gently knead continuously to peel off the outer skin to the greatest extent, and continue to roll until the mass no longer decreases and reaches a constant weight.

[0043] (3) Add water to the residue containing rubber filaments and stir at a high speed, the stirring rate is 3000rpm, the stirring time is 4 minutes, and the stirring temperature is 40°C; sedimentation and separation are repeated twice to obtain dandelion rubber. The purity of the gel was 87.4%.

Embodiment 2

[0045] Region: Hainan

[0046] (1) The dried root of dandelion rubber grass is cleaned and dried at room temperature;

[0047](2) Treat the root with a milling groove, and keep rolling until there is no more residue rolling out, and the quality reaches a constant weight; the residue containing glue silk is obtained for ball milling to further remove the residue

[0048] (3) Add water to the mixture containing rubber filaments and stir at a high speed, the stirring rate is 6000rpm, the stirring time is 3 minutes, and the stirring temperature is 60°C; sedimentation and separation are repeated 3 times to obtain dandelion rubber. The purity of the gel was 90.6%.

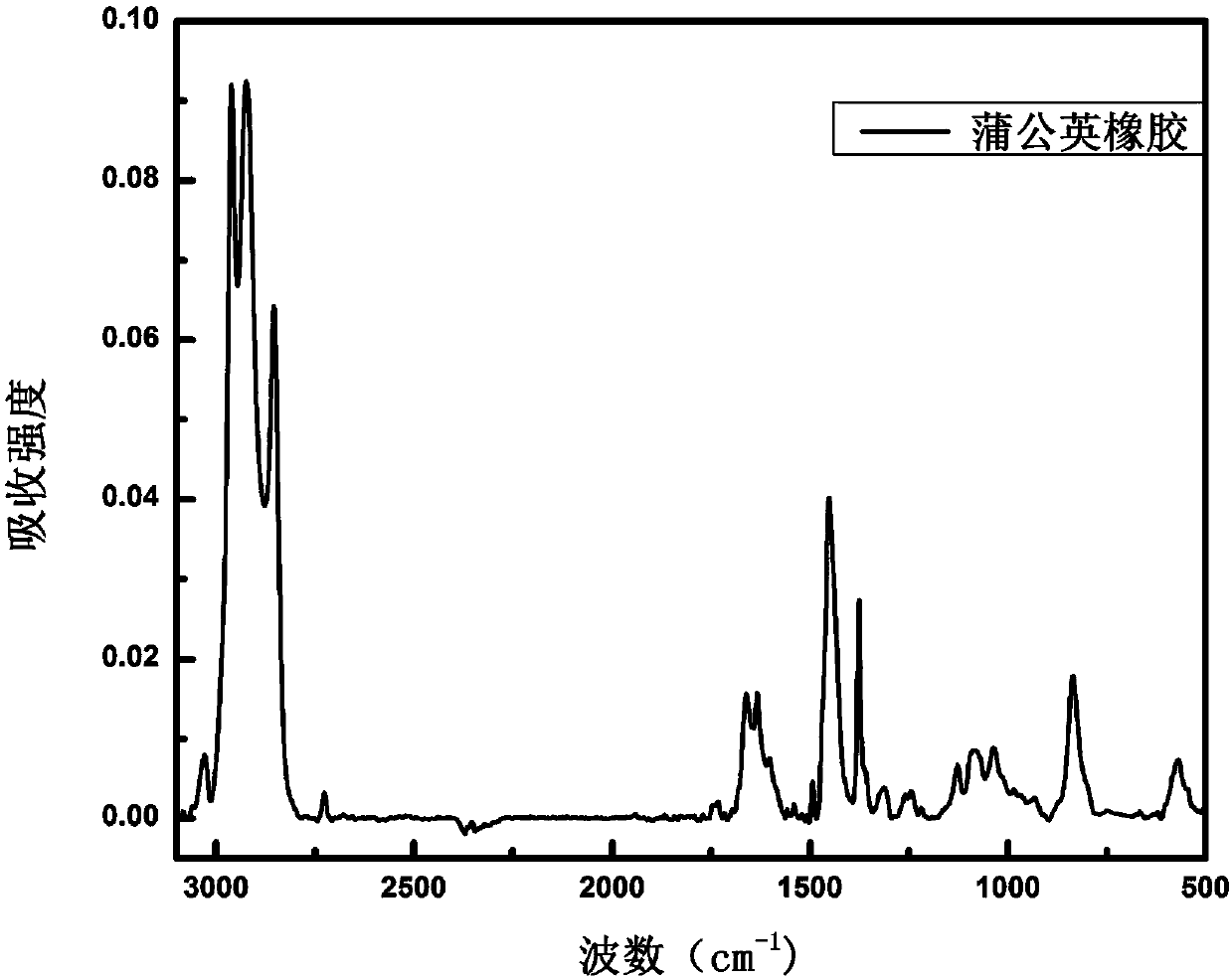

[0049] Tested by infrared, such as figure 1 As shown, the spectrum contains methylene, carbon-carbon double bond, methyl group, etc. It is found that the stretching vibration peak of the cis-polyisoprene skeleton at 835cm-1 is obvious, which proves that the product we obtained is indeed the rubber in dandelion compone...

Embodiment 3

[0051] Region: Heilongjiang

[0052] (1) The dried root of dandelion rubber grass is cleaned and dried at room temperature;

[0053] (2) Crushing the dandelion root with a blender, sieving, and removing the residue; obtaining the residue containing gum filaments and performing ball milling to further remove the residue.

[0054] (3) Add water to the residue containing rubber filaments and stir at high speed, the stirring rate is 6500rpm, the stirring time is 2 minutes, and the stirring temperature is 80°C; sedimentation and separation are repeated 5 times to obtain dandelion rubber. The purity of the gel was 88.2%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com