Novel anti-deformation device for steel cylinder cutting

An anti-deformation, steel cylinder technology, used in shearing devices, accessories of shearing machines, metal processing equipment, etc., can solve the problems of large diameter changes, difficult to accurately control, inaccurate cutting, etc., to achieve smooth end surface of steel cylinders, Improve the cutting accuracy and use a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings.

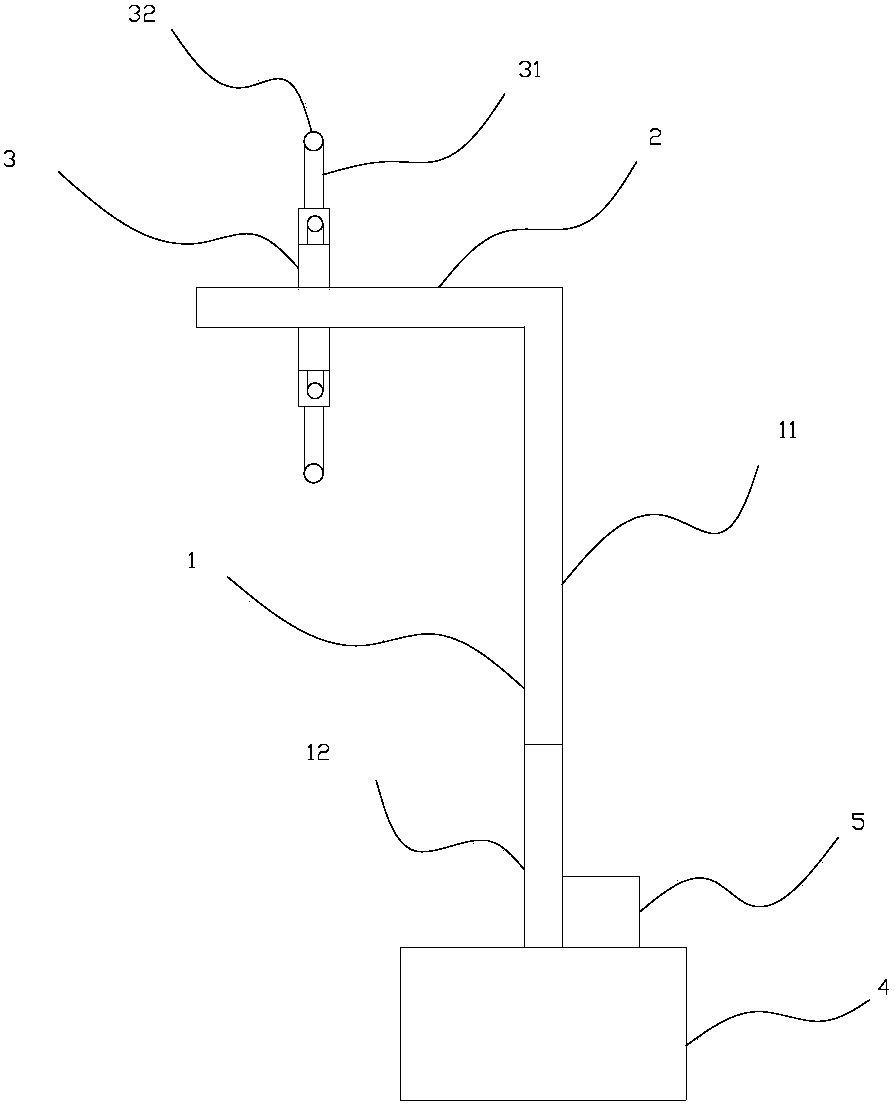

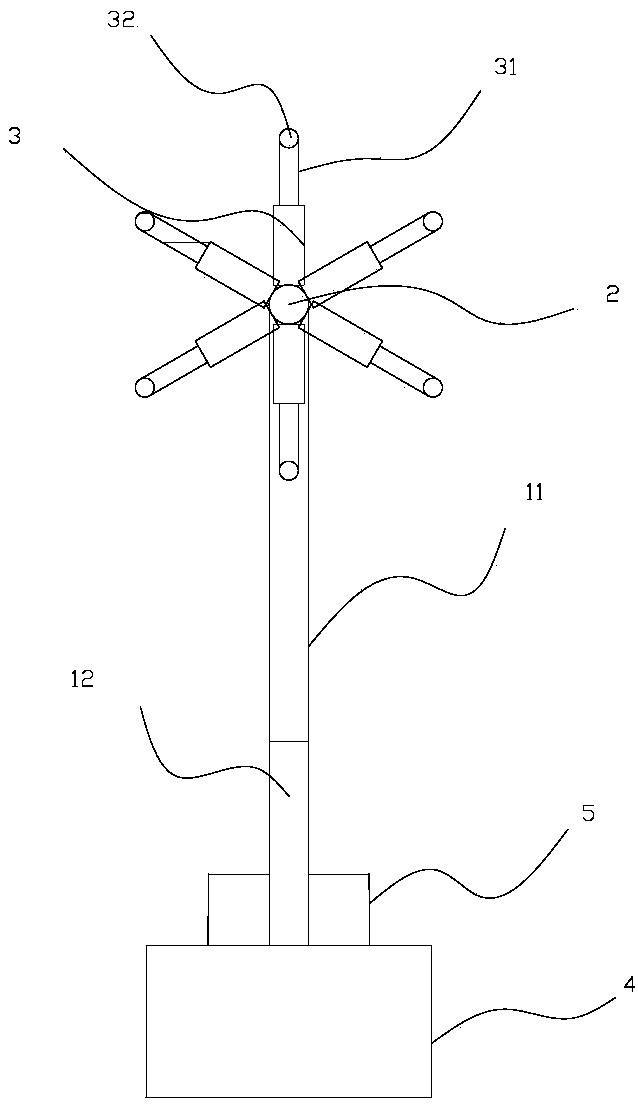

[0019] Such as Figure 1-3 As shown, the present invention includes an inverted L-shaped support bar, the support bar includes a vertical bar 1 and a cross bar 2, and the radial direction of the cross bar 2 is provided with some uniformly distributed cylinders 3, and the piston of the cylinder 3 The end of the rod one 31 is provided with a ball 32;

[0020] Some of the cylinders 3 are connected to the same motor 5, so that the cylinder one 3 works simultaneously under the drive of the motor 5;

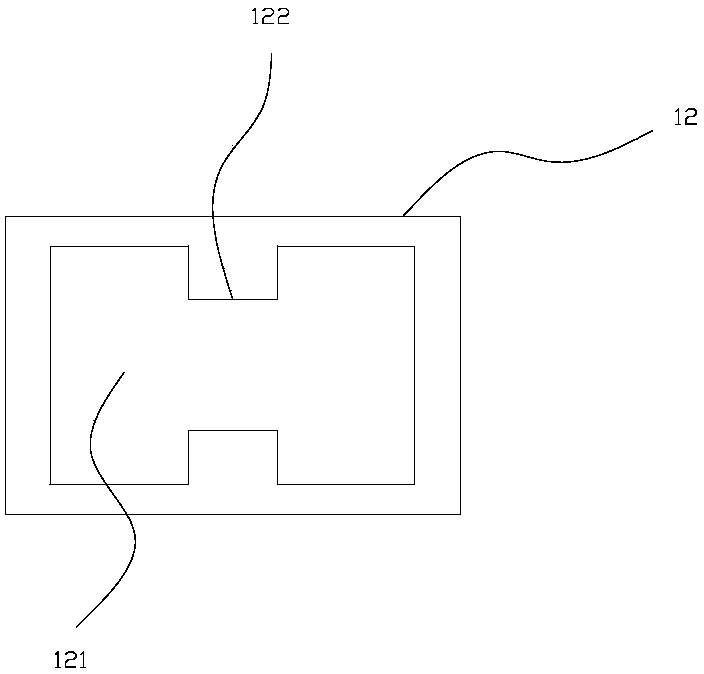

[0021] The vertical rod 1 includes an upper rod 11 and a lower rod 12, the top of the lower rod 12 is provided with a groove 121 extending downward, and the two opposite side walls of the groove 121 are provided with symmetrical slideways 122 , the rod wall of the upper rod 11 fits in the groove 122 and can slide in the groove 122;

[0022] A cylinder 2 is arranged in the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap