Cutting device

A technology of cutting equipment and cutting device, which is applied in the direction of shearing machine equipment, metal processing equipment, shearing device, etc., can solve the problems of low production efficiency, complicated fixing device, time-consuming and labor-intensive, etc., so as to avoid damage and reduce multiple positioning , Improve the effect of machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

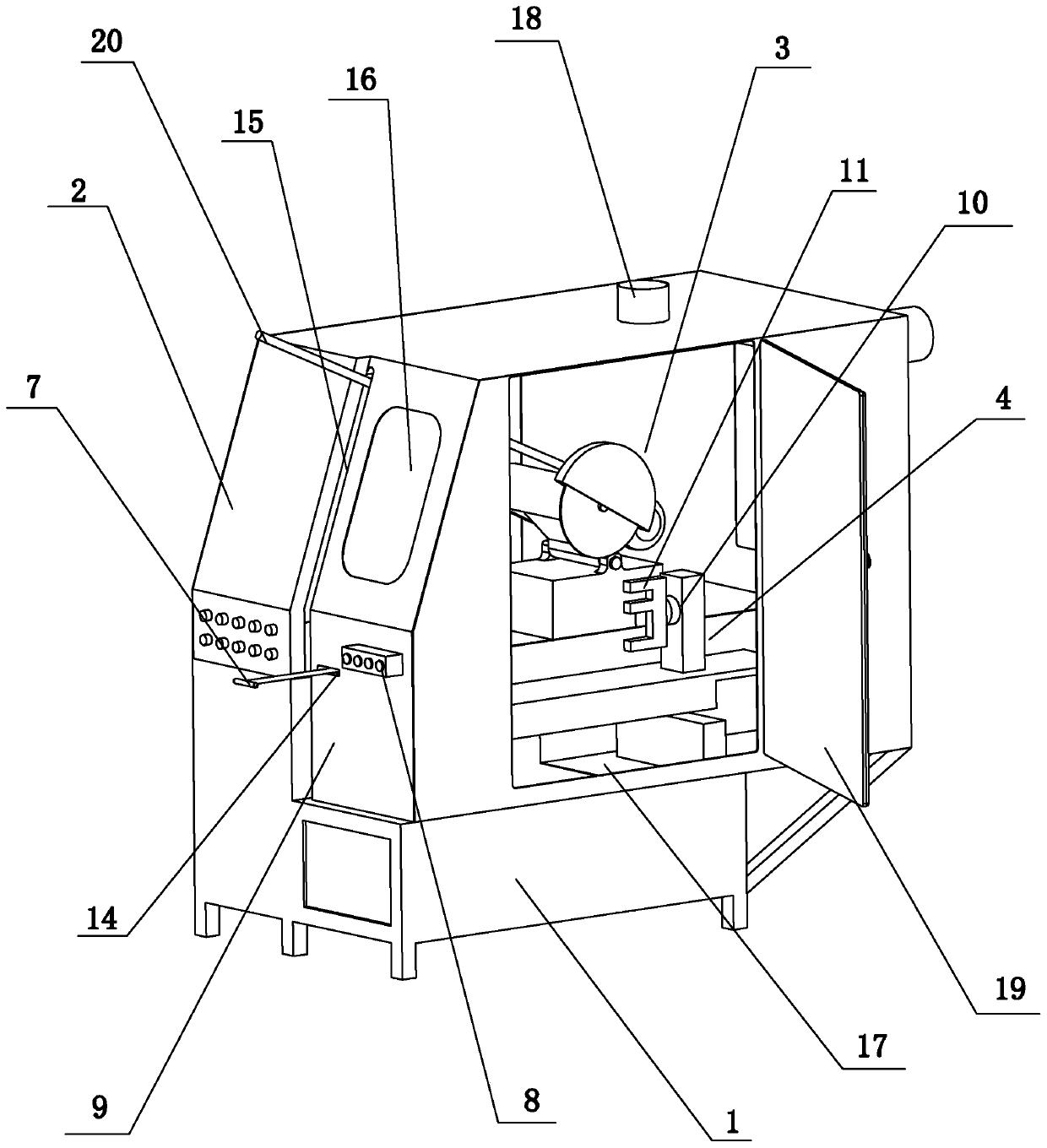

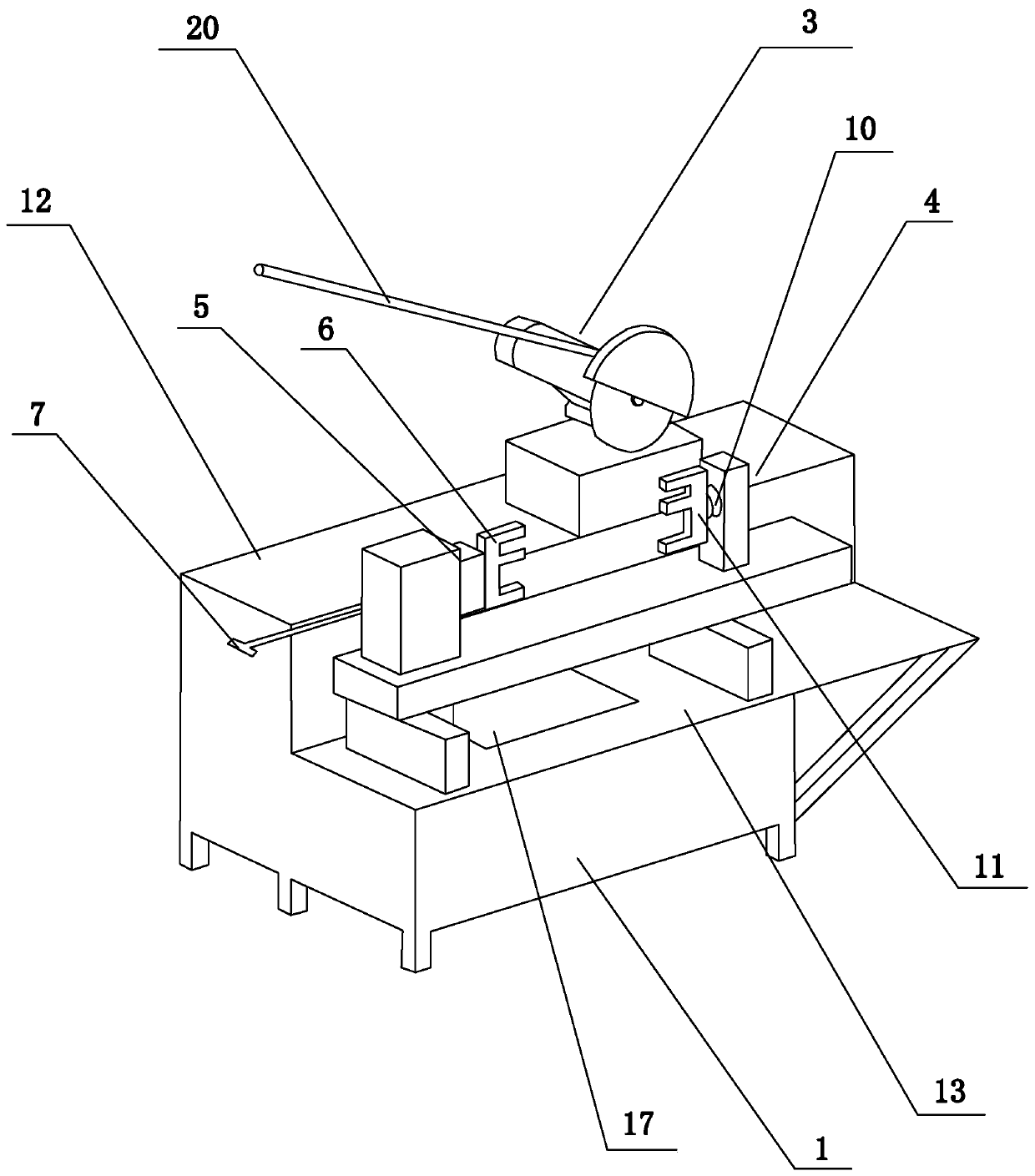

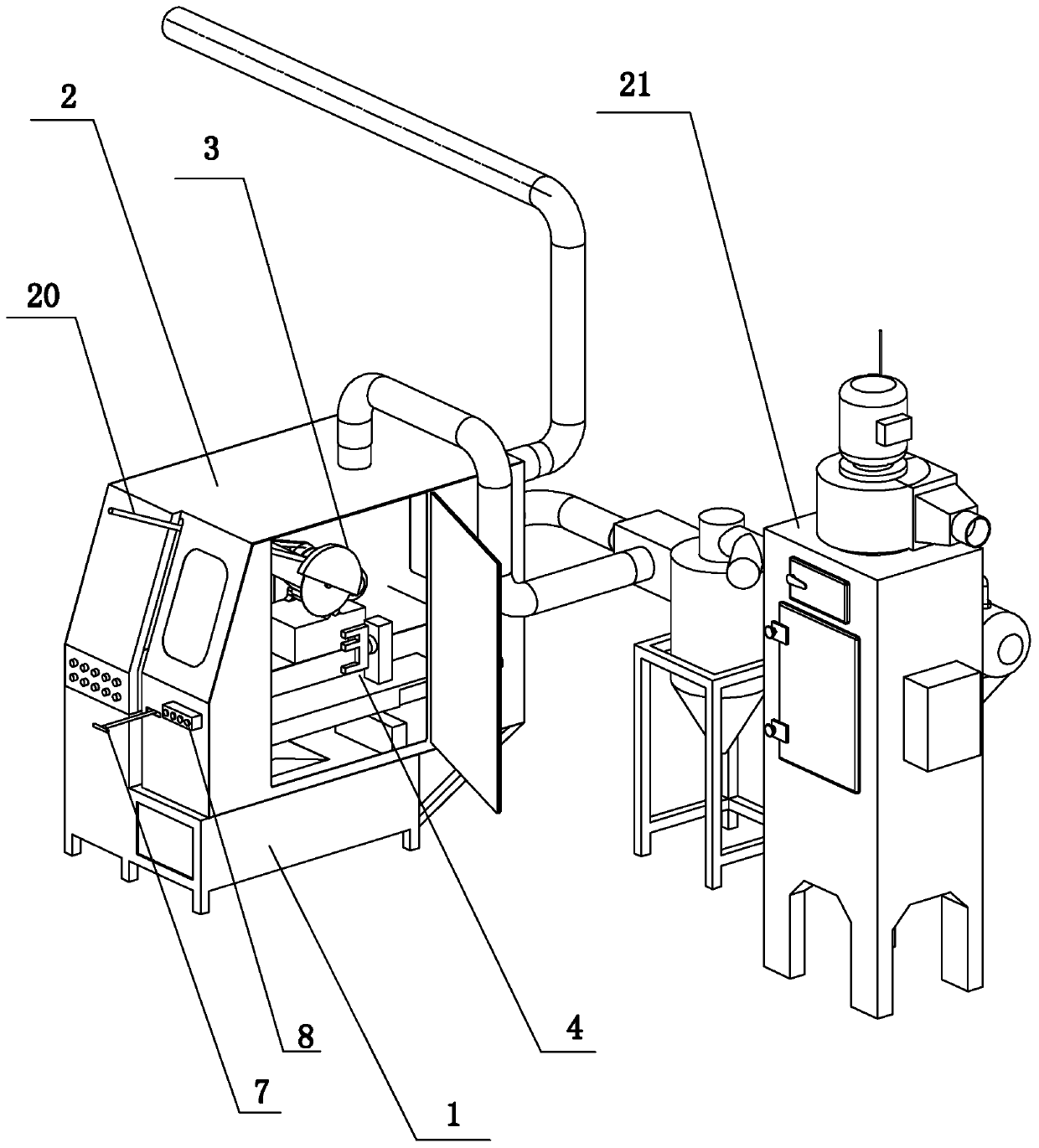

[0025] Embodiment one: see Figure 1~3 As shown, a cutting device includes a base 1, a cutting assembly 3, a clamp assembly 4 and a dust cover 2, and the cutting assembly 3 and the clamp assembly 4 are arranged around the dust cover 2 and the base 1 In the operating space formed by the combination, the cutting assembly 3 and the clamp assembly 4 are arranged in the dustproof cover 2 to ensure a clean and tidy working environment, and the arrangement of the dustproof cover 2 can also avoid the injury of the cutting waste to the staff.

[0026] see figure 2 As shown, the clamp assembly 4 includes a first clamp assembly and a second clamp assembly, and the first clamp assembly is arranged opposite to the second clamp assembly; the first clamp assembly includes a first rotating device 5, which is arranged on the The first clamp 6 on the first rotating device 5, the first pull rod 7 for controlling the horizontal movement of the first rotating device 5 and the controller 8 for co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com