Multifunctional automatic punching, laminating, tape-preparing and cutting device and automatic punching, laminating, tape-preparing and cutting method for tail edge of coiled material

An automatic punching and multi-functional technology, which is applied in winding strips, chemical instruments and methods, transportation and packaging, etc., can solve the problems that cannot meet the needs of automatic high-speed production, poor glue uniformity, high shutdown rate, etc., to achieve The effect of less waste, good consistency, and reduced waste size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

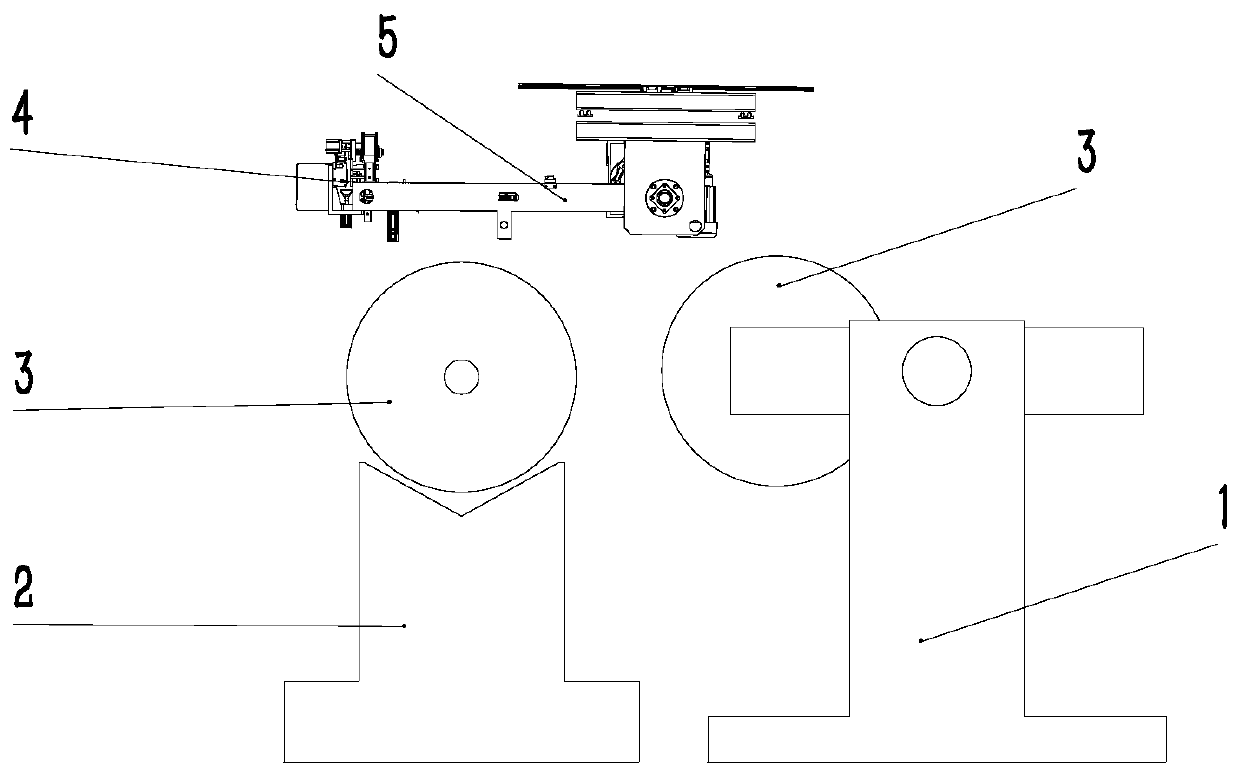

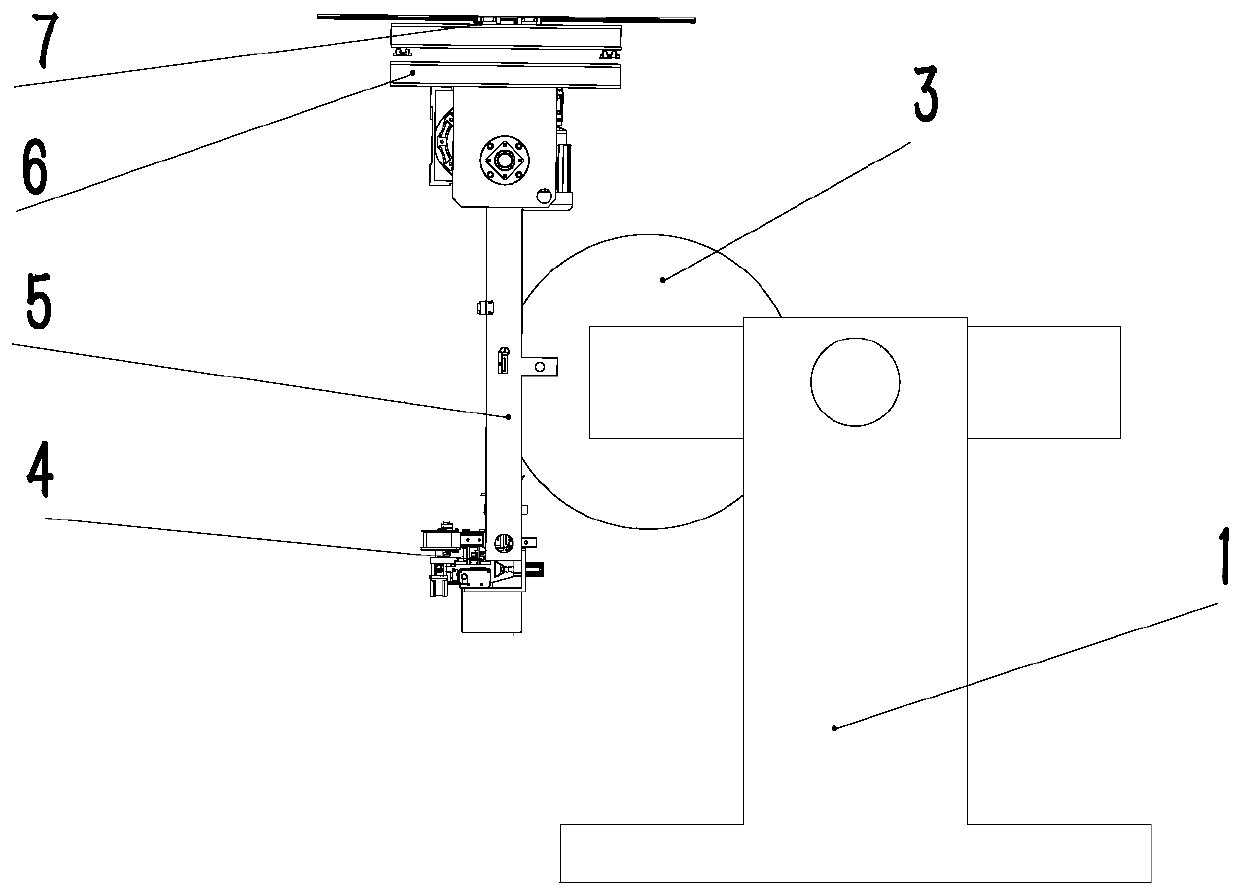

[0035] See Figure 1 to Figure 4 , the present invention has a winding module 1, a loading and unloading trolley 2 and a coiled material 3; The coiled material 3 is wound on the rotating shaft of the winding module 1; a mechanical arm 5 is arranged above the winding module 1; a punching and glue preparation and cutting mechanism 4 is installed on one end of the mechanical arm 5, and the other end is rotatably connected to a mechanical The mechanical arm on the arm roll diameter tracking mechanism 7 is centered on the deviation correction mechanism 6, and the mechanical arm 5 is driven to rotate by a motor, cylinder or oil cylinder; the mechanical arm roll diameter tracking mechanism 7 is slidably arranged on the guide rail of the frame.

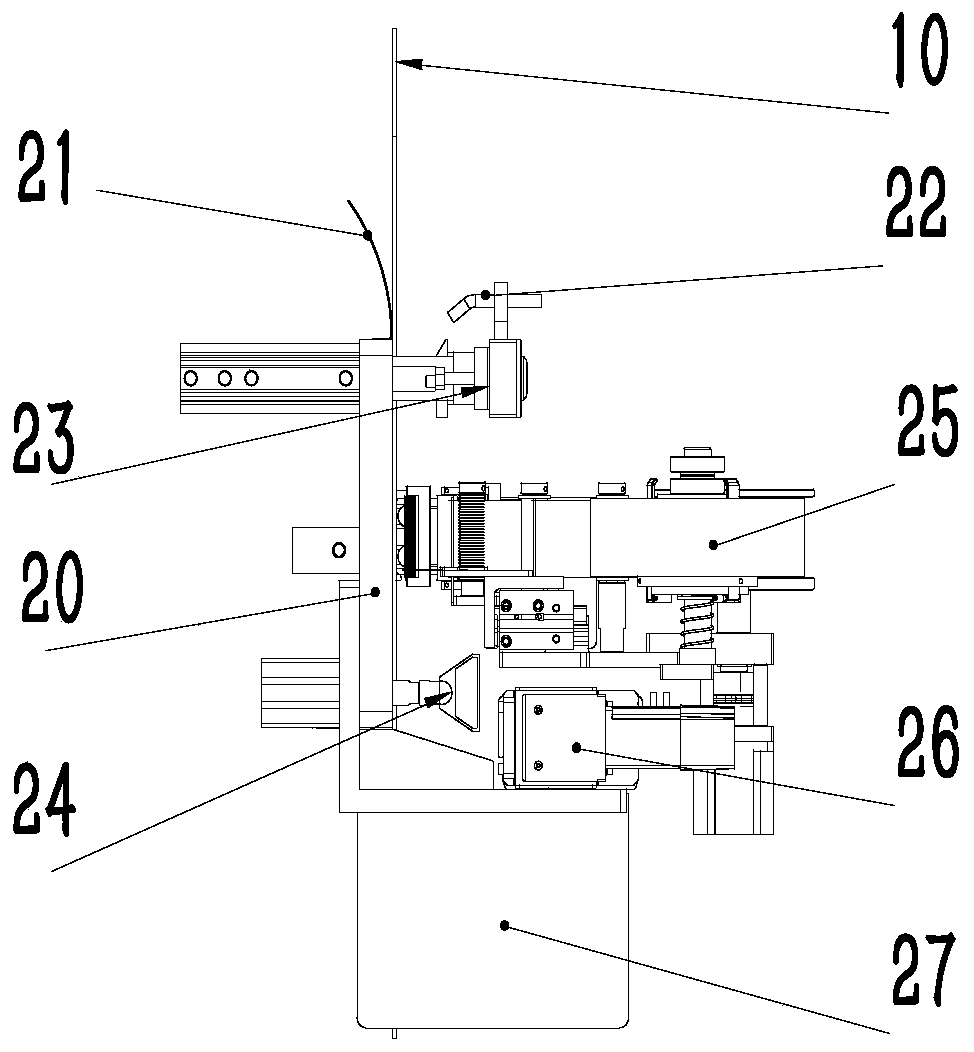

[0036] Punching and glue preparation cutting mechanism 4 comprises punching assembly 23, pressing belt assembly 24, pasting glue cutting assembly 25, linear drive assembly 26 and glue pasting head assembly 28; Punching assembly 23 and pressin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap