Pallet part riveting device and method for riveting the pallet using the device

A technology for a riveting device and a plate piece, applied in the field of plate riveting device, can solve problems such as multiple positioning, and achieve the effects of reducing the replacement of molds, saving riveting time, and improving riveting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

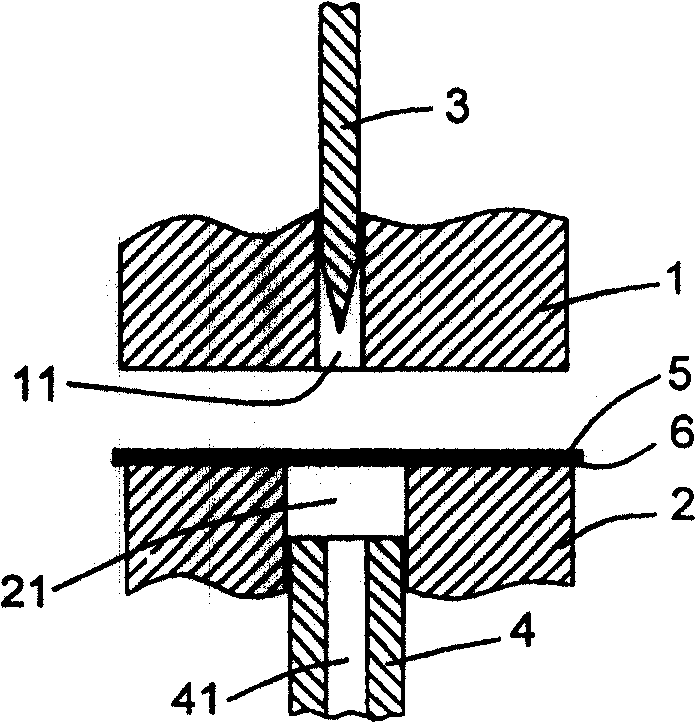

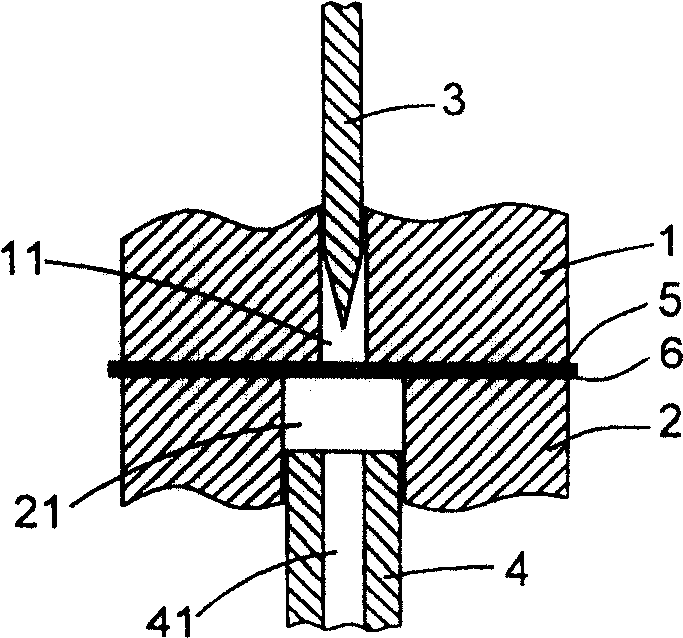

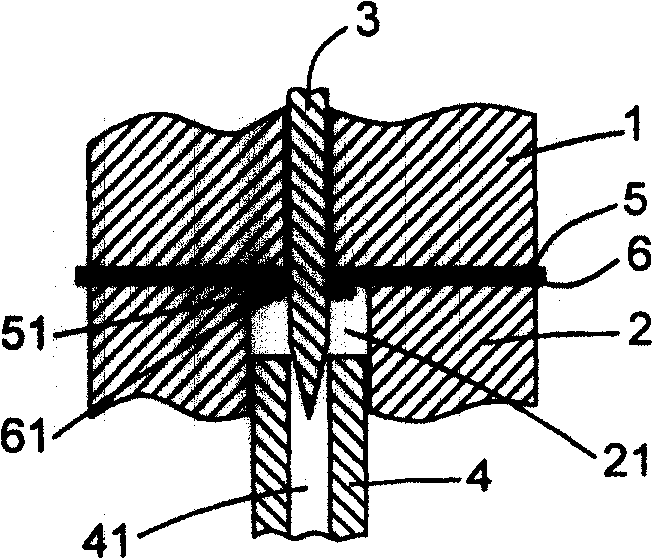

[0018] see figure 1 , is a preferred embodiment of the panel riveting device of the present invention, and the panel riveting device includes an upper mold 1 , a lower mold 2 , a punch 3 and a flange assembly 4 . The upper and lower molds 1, 2 are set up and down, and can be aligned in a separate and combined manner. There is a punching pin hole 11 inside the upper mold 1, and the punching pin 3 is movably accommodated in the punching pin hole 11. The lower-mold 2 is provided with a guide hole 21 , the guide hole 21 is aligned with the punch hole 11 , and the flanging assembly 4 is movably accommodated in the guide hole 21 . The needle head of the punching needle 3 is tapered to facilitate piercing the first plate 5 and the second plate 6 . A channel 41 is provided in the flange assembly 4 for the punching needle 3 to be inserted into.

[0019] The cross-sectional shape of the punching pin 3 , the flange assembly 4 , the punching pin hole 11 , the guide hole 21 and the chan...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap