AGV layout method and system, electronic device and storage medium

A layout method and layout technology, applied in the field of warehousing and logistics, can solve problems such as low warehouse delivery efficiency and unreasonable AGV layout, and achieve the effect of improving delivery efficiency, improving handling efficiency, and reducing handling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

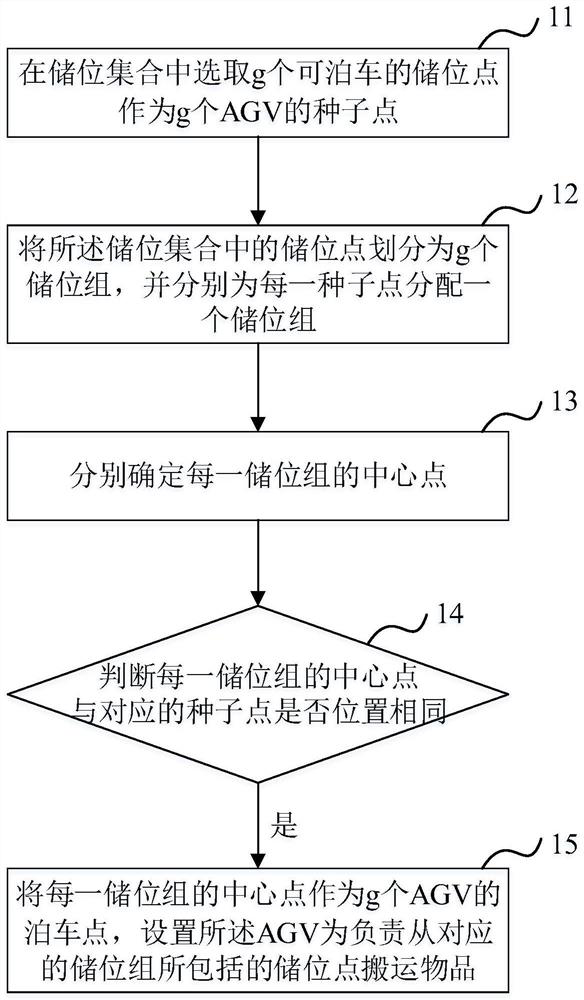

[0044] This embodiment provides an AGV layout method. Such as figure 2 As shown, the AGV layout method includes:

[0045] Step 11. Select g storage points that can be parked in the storage space set as seed points for g AGVs, where g is a positive integer.

[0046] Step 12. Divide the storage points in the storage set into g storage groups, and assign a storage group to each seed point. The cost from the storage point included in the storage location group to the corresponding seed point is the lowest, and the cost is determined according to the outbound frequency of the storage location and the distance between the storage location and the seed point.

[0047] Step 13. Determine the center point of each storage location group respectively.

[0048] Step 14, judging whether the center point of each storage group is in the same position as the corresponding seed point, and executing step 15 if the positions are the same.

[0049] Step 15. Use the central point of each stor...

Embodiment 2

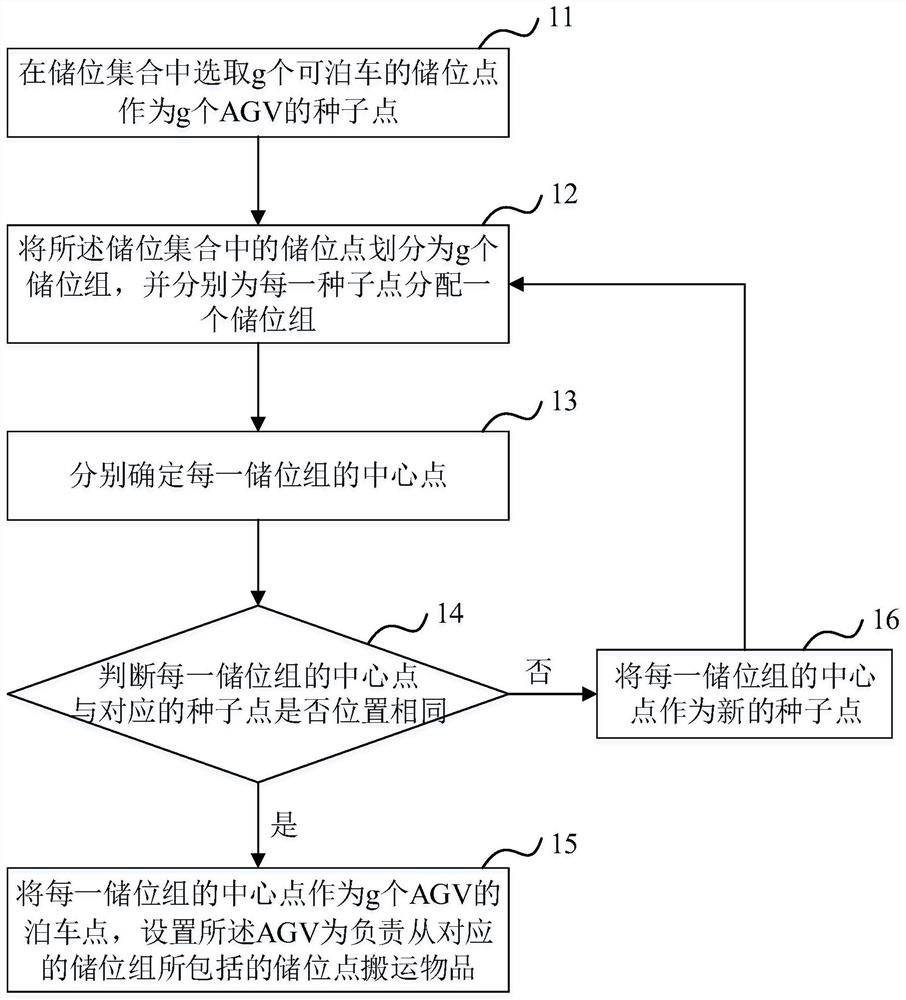

[0054] The AGV layout method of embodiment 2 is basically the same as the AGV layout method of embodiment 1, the difference is that, as image 3 As shown, the AGV layout method of the present embodiment also includes:

[0055] When it is determined in step 14 that the positions are different, step 16 is executed.

[0056] Step 16. Use the central point of each storage group as a new seed point, and then execute Step 12.

[0057] The AGV layout method of this embodiment re-divides the storage group when the center of the storage group is different from the corresponding seed point position, then determines the center point again and performs position judgment, and loops until the center point of each storage group and the corresponding seed point The position of the seed point is the same, and the storage group is finally determined and the parking point is set, so that each AGV can be fully utilized, the storage group responsible for handling is defined, and the work efficien...

Embodiment 3

[0059] The AGV layout method in Embodiment 3 is a further improvement on the AGV layout method in Embodiment 2. Such as Figure 4 As shown, the AGV layout method of the present embodiment includes:

[0060] Step 111, randomly select g storage points that can be parked in the storage space set as the seed points of g AGVs, where g is a positive integer. Of course, the present invention is not limited thereto. In other embodiments of the present invention, the g storage points that can be parked can also be selected according to specific rules, and the specific rules are determined according to actual needs.

[0061] Step 121. Calculate the cost from each storage point to each seed point in the storage location set.

[0062] Step 122: Compare the cost of the storage point to each seed point, and divide the storage point into the storage group corresponding to the seed point with the lowest cost.

[0063] Step 131. Calculate the average value of the cost from each storage poin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com