High-density resistivity method electrode suitable for open iron mine stope

A technology of high-density resistivity and iron ore, which is applied in the direction of re-radiation, electric/magnetic exploration, and re-radiation of sound waves, etc., can solve the problem of affecting the accuracy of data collection, the deterioration of the conductive contact between the electrode and the earth, and the inability of the electrode to be completely Insert problems such as the ground surface to ensure the accuracy of data collection and improve the effect of conductive contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

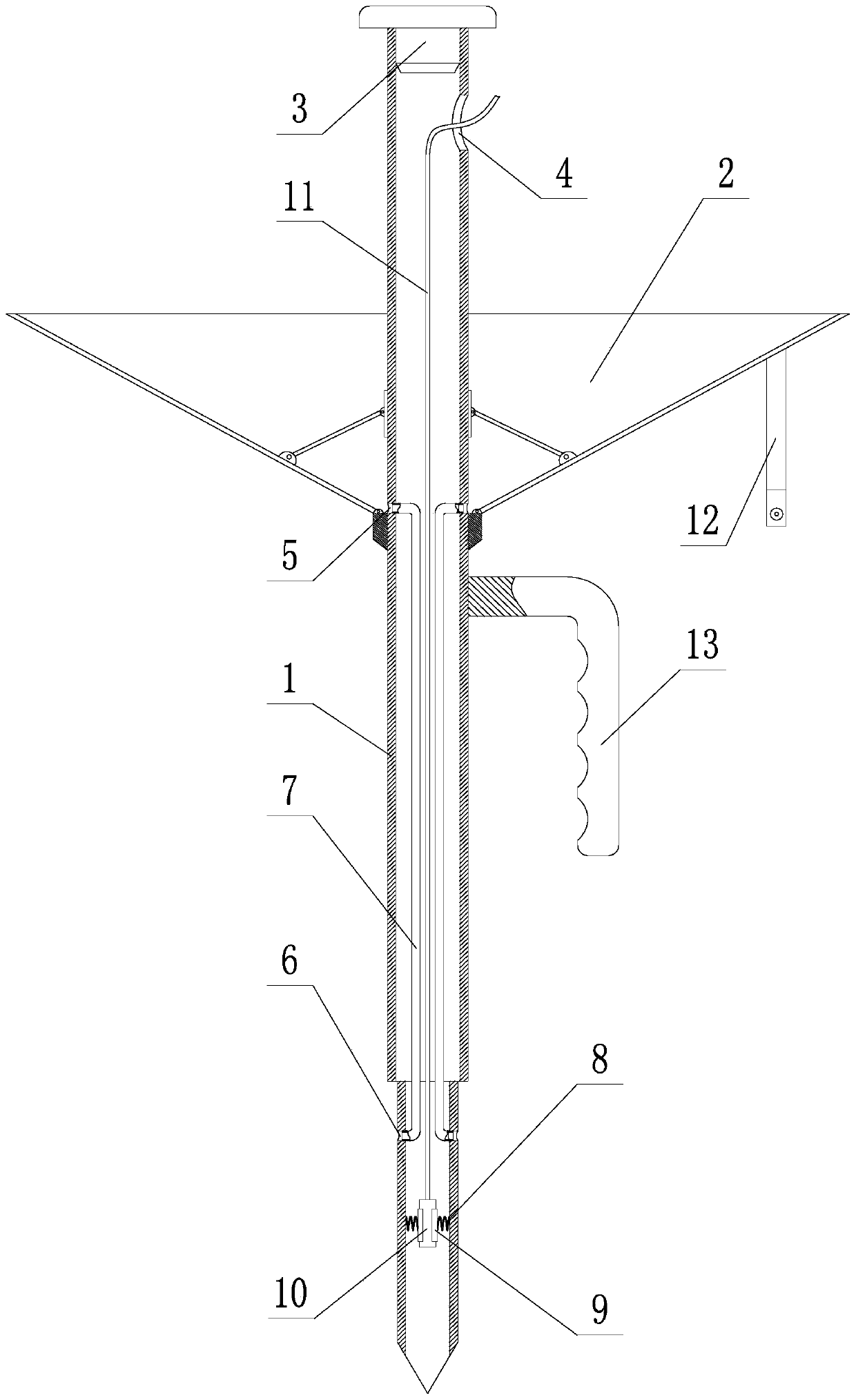

[0018] Such as figure 1 As shown, a high-density resistivity method electrode suitable for open-pit iron ore stope includes a hollow rod body 1 and a light shield 2, a hammer cap 3 is installed on the top of the hollow rod body 1, and the hollow body below the hammer cap 3 A wire outlet hole 4 is provided on the rod body 1, and the shading cover 2 is arranged on the hollow rod body 1 below the wire outlet hole 4; Pyramid structure; the shading cover 2 adopts a funnel-shaped structure, and a water injection hole 5 is opened on the hollow rod body 1 corresponding to the inner bottom of the shading cover 2, and a water outlet hole 6 is opened on the pyramid surface of the hollow rod body 1 entering the ground. 5 and the water outlet hole 6 are connected with a water guide pipe 7; a spring 8 is installed in the central channel of the hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com