Pressure measurement device for wing elasticity shrinkage similarity model of large-size transport plane

A technology similar to model and transport aircraft, applied in the field of wind tunnel test, can solve the problems of inability to directly install the pressure measuring tube, large deformation, difficult to achieve, etc., and achieve the effect of simple and convenient processing method, light weight and simple installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The structure of the present invention will be further described below with reference to the accompanying drawings.

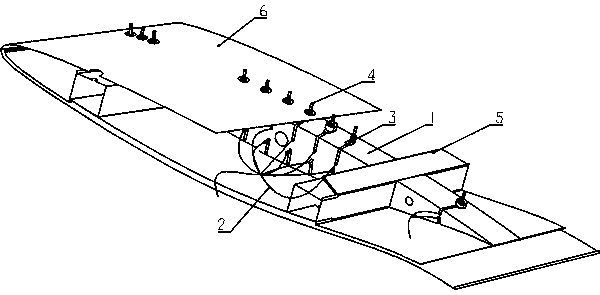

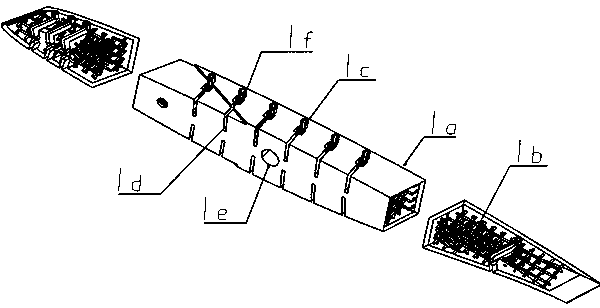

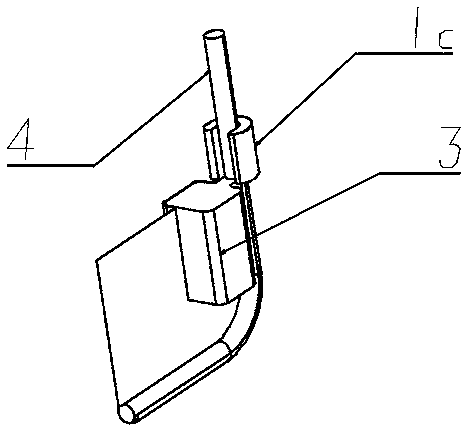

[0014] figure 1 , 2 , 3 show the schematic diagram of the structure of the pressure measuring device of the wind tunnel test model similar to the elastic ratio of the wing. In the figure, the pressure measuring device used for the similar model of large transport aircraft wing elastic reduction includes pressure measuring hose bracket 1, pressure measuring hose 2, top block 3, pressure measuring steel pipe 4, spar 5 and skin 6. The upper and lower surfaces of the pressure measurement hose bracket 1 are attached to the skin 6 and bonded to the skin 6 and the spar 5 by resin glue. The pressure measurement steel pipe 4 is connected to the pressure measurement hose 2, and the pressure measurement steel pipe 4 is built into the pressure measurement In the pressure measuring pipe groove 1d of the pipe bracket 1, the pressure measuring steel pipe 4 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com