Toilet bowl

A technology for toilets and pipes, which is applied in the field of sanitary ware. It can solve the problems of complex mold making process and inability to make full use of water kinetic energy, and achieve the effects of simplifying the processing process of the undercut position, shortening the product production cycle, and enhancing the flushing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the technical solution of the present invention will be further described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to the following implementation manners.

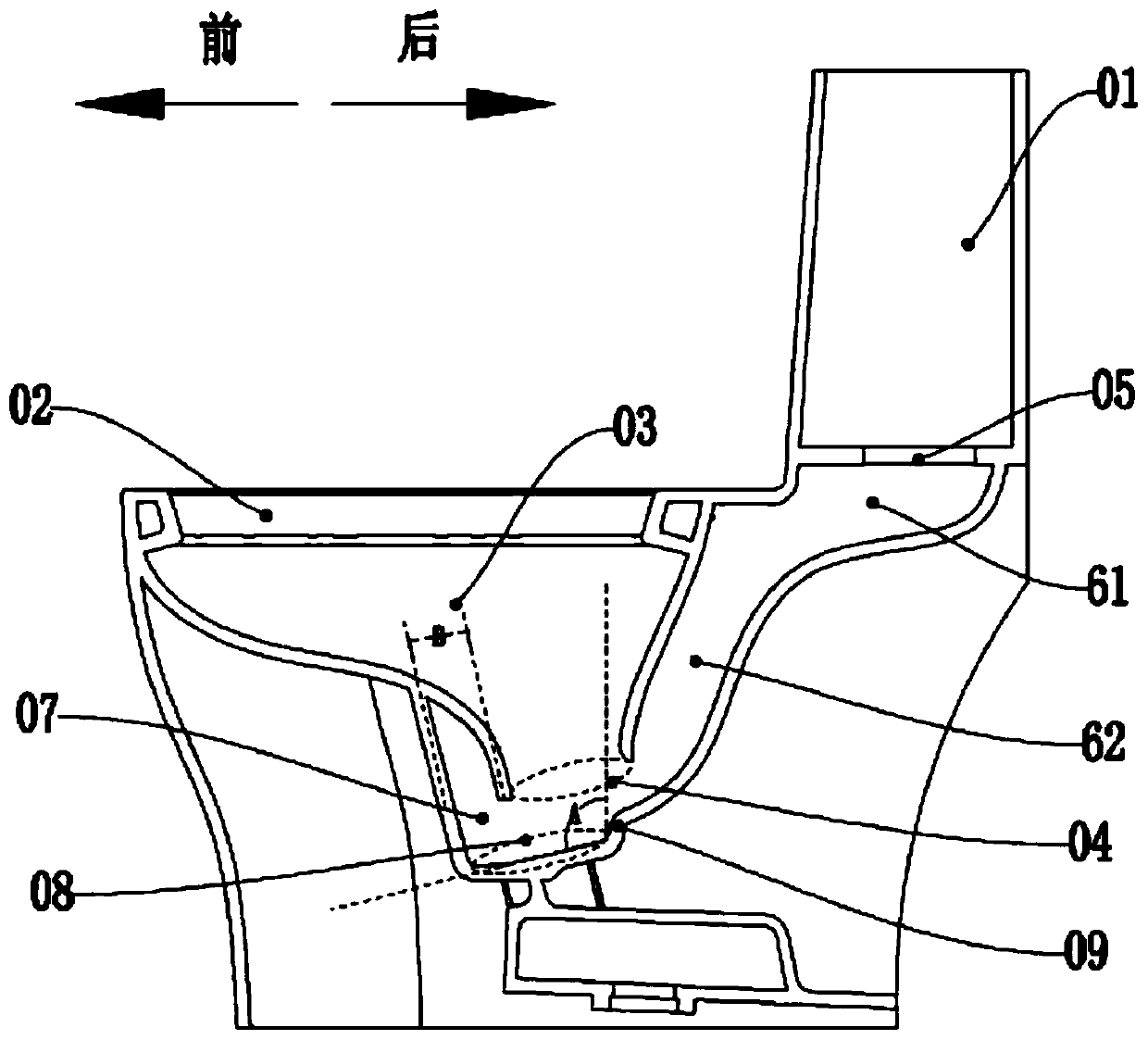

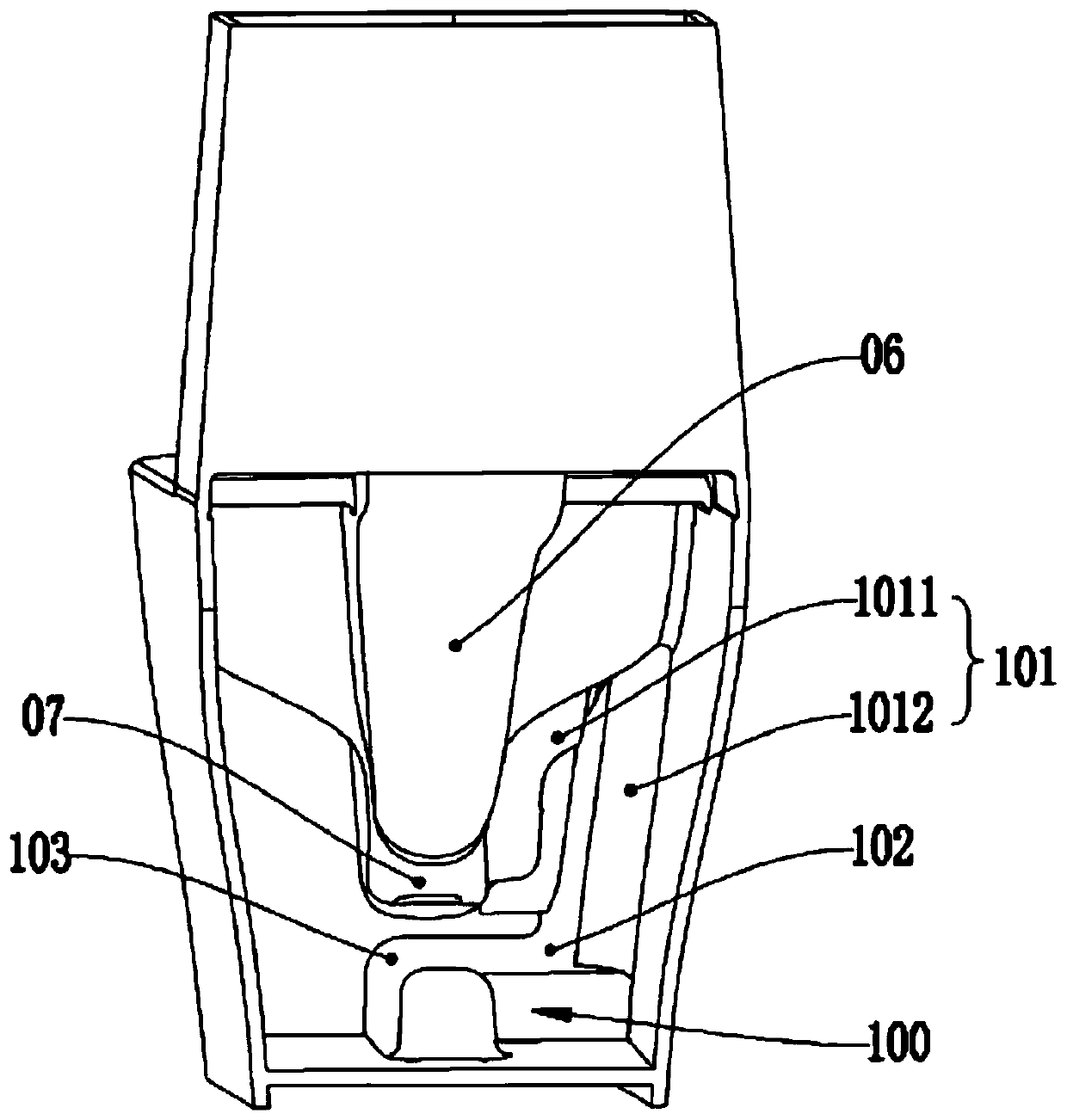

[0026] Such as figure 1 or figure 2 As shown, a toilet includes a toilet body, a water tank 01, a flushing pipeline and a water storage pipeline 100. The toilet body includes a urinal 03, a toilet seat 02 and a urinal sewage outlet 04. The starting part 61 of the flushing pipe and the vertical part 62 of the main flushing pipe, the water inlet end of the starting part 61 of the main flushing pipe communicates with the water outlet, and the water outlet end of the starting part 61 of the main flushing pipe The water inlet end of the vertical part 62 of the main flushing pipe is connected, the water outlet end of the vertical part 62 of the main flushing pipe is connected with the sewage outlet 04 of the urinal, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com