A negative flow control excavator attachment flow control device, method and excavator

A flow control device and flow control technology, applied in the direction of earth mover/shovel, construction, etc., can solve the problems of unstable operation, fast speed, excessive rotation flow of attachments, etc., and achieve the effect of ensuring reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

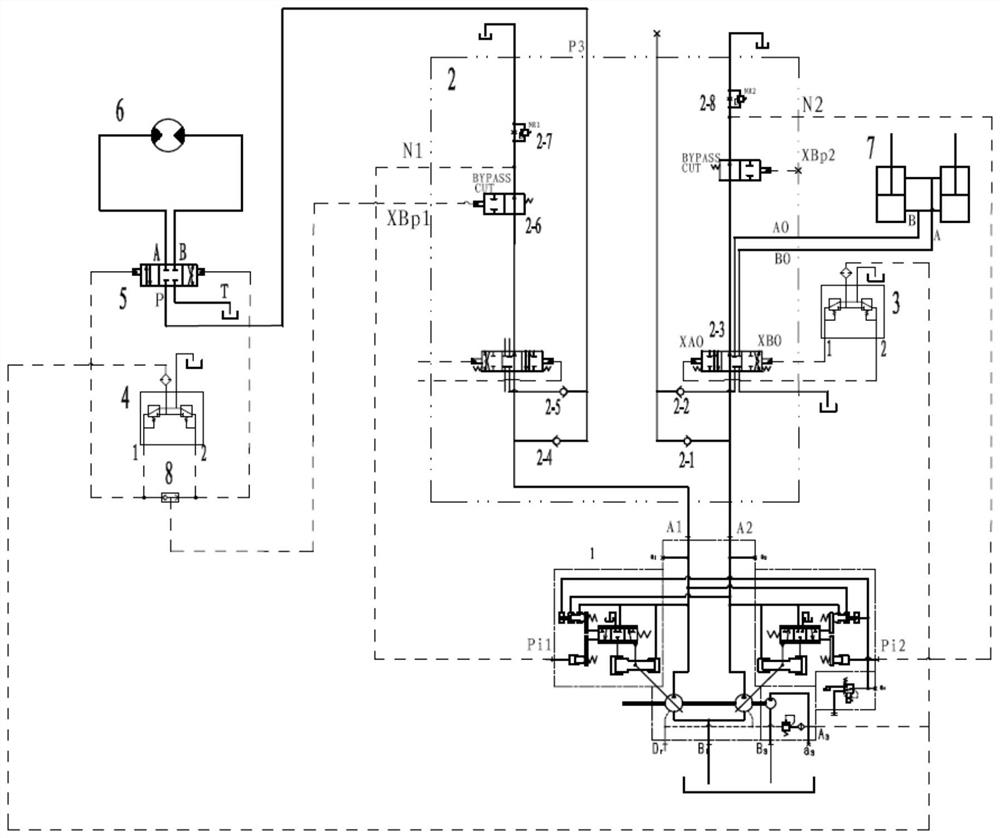

[0029] Such as figure 1 As shown, it is a simplified schematic diagram of an existing negative flow control excavator equipped with attachments, the main valve part has been greatly deleted, and only the part useful to this patent is retained.

[0030] Principle of attachment clamping oil cylinder: operate clamping pilot valve 3, input pilot pressure oil from port 1 of clamping pilot valve 3 to drive the XBO port of the first spool 2-3 of the main valve, and replace the first spool 2-3 of the main valve direction, the main pressure oil passes through the main pump A2 port, passes through the first check valve 2-1 and the second check valve 2-2 in the main valve, passes through the first spool 2-3 of the main valve to the oil port AO, and then Clamp the B port of the oil cylinder 7 through AO, push the oil cylinder to clamp, return the oil through the A port, pass through BO, and then return to the oil tank through the first spool 2-3 of the main valve, because the first spool ...

Embodiment 2

[0041] Embodiment 2 of the present disclosure provides a negative flow control excavator attachment flow control method, using the negative flow control excavator attachment flow control device described in Embodiment 1;

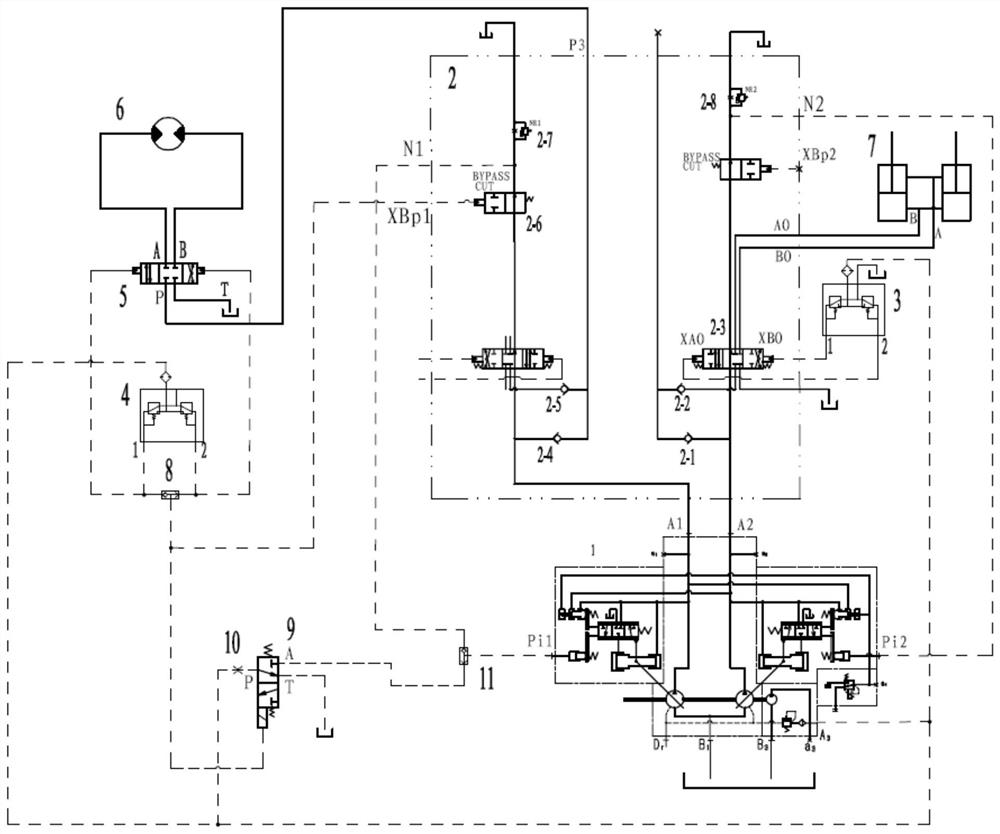

[0042] (1) Working method of attachment clamping oil cylinder: operate clamping pilot valve 3, input pilot pressure oil from port 1 of clamping pilot valve 3 to drive the XBO port of the first spool 2-3 of the main valve, and the first spool of the main valve 2-3 reversing, the main pressure oil passes through the A2 port of the main pump, passes through the first check valve 2-1 and the second check valve 2-2 in the main valve, and reaches the oil through the first spool 2-3 of the main valve. Port AO, and then through AO, enter the oil into the B port of the clamping cylinder 7, push the oil cylinder to clamp, return the oil through the A port, pass through the BO, and then return to the fuel tank through the first spool 2-3 of the main valve, because the f...

Embodiment 3

[0045] Embodiment 3 of the present disclosure provides a negative flow control excavator attachment flow control system, including the negative flow control excavator attachment flow control device described in Embodiment 1 of the present disclosure.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com