Automatic valve block feeding mechanism

A technology of automatic feeding and valve block, used in conveyors, conveyor objects, rotary conveyors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

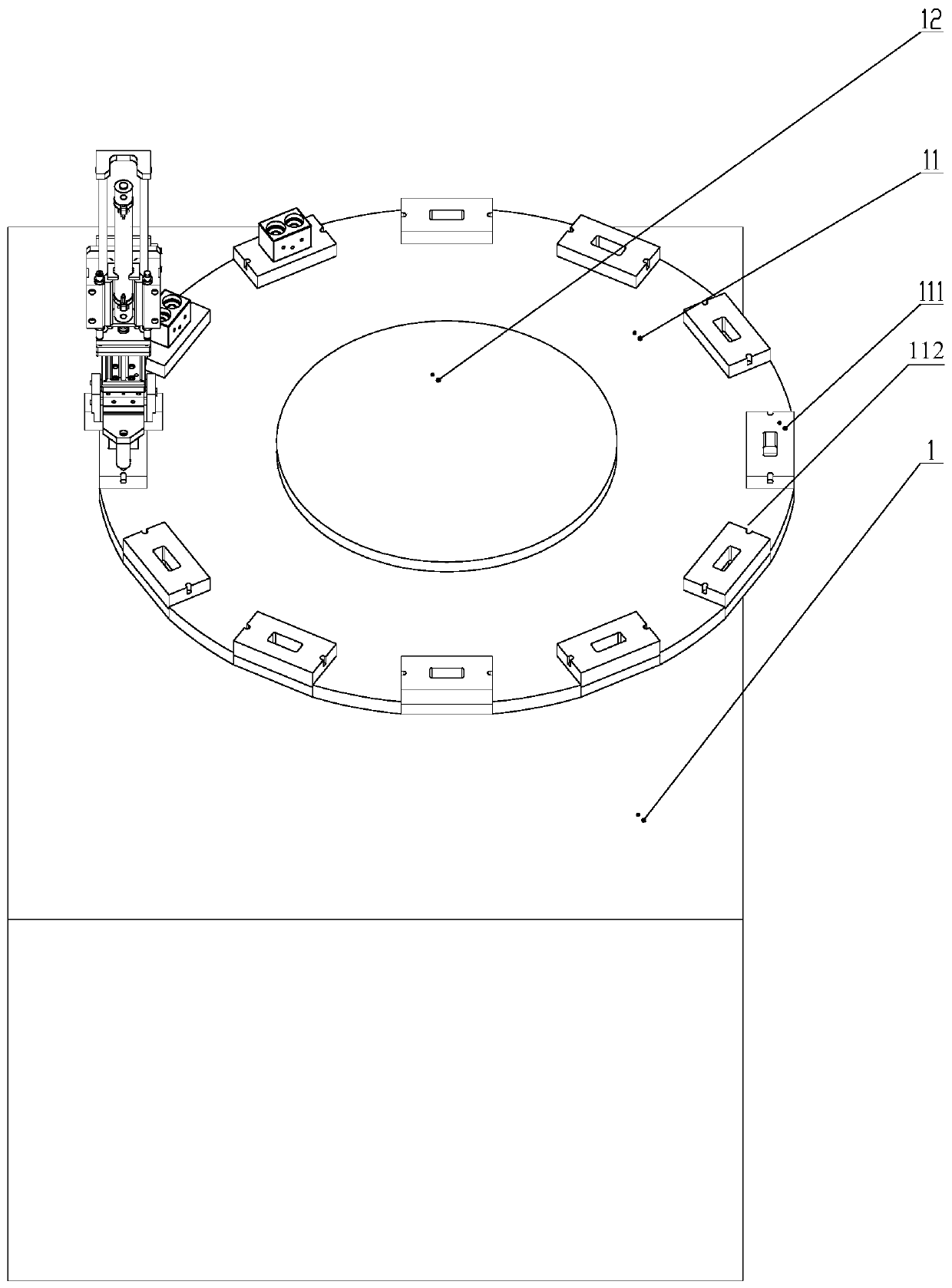

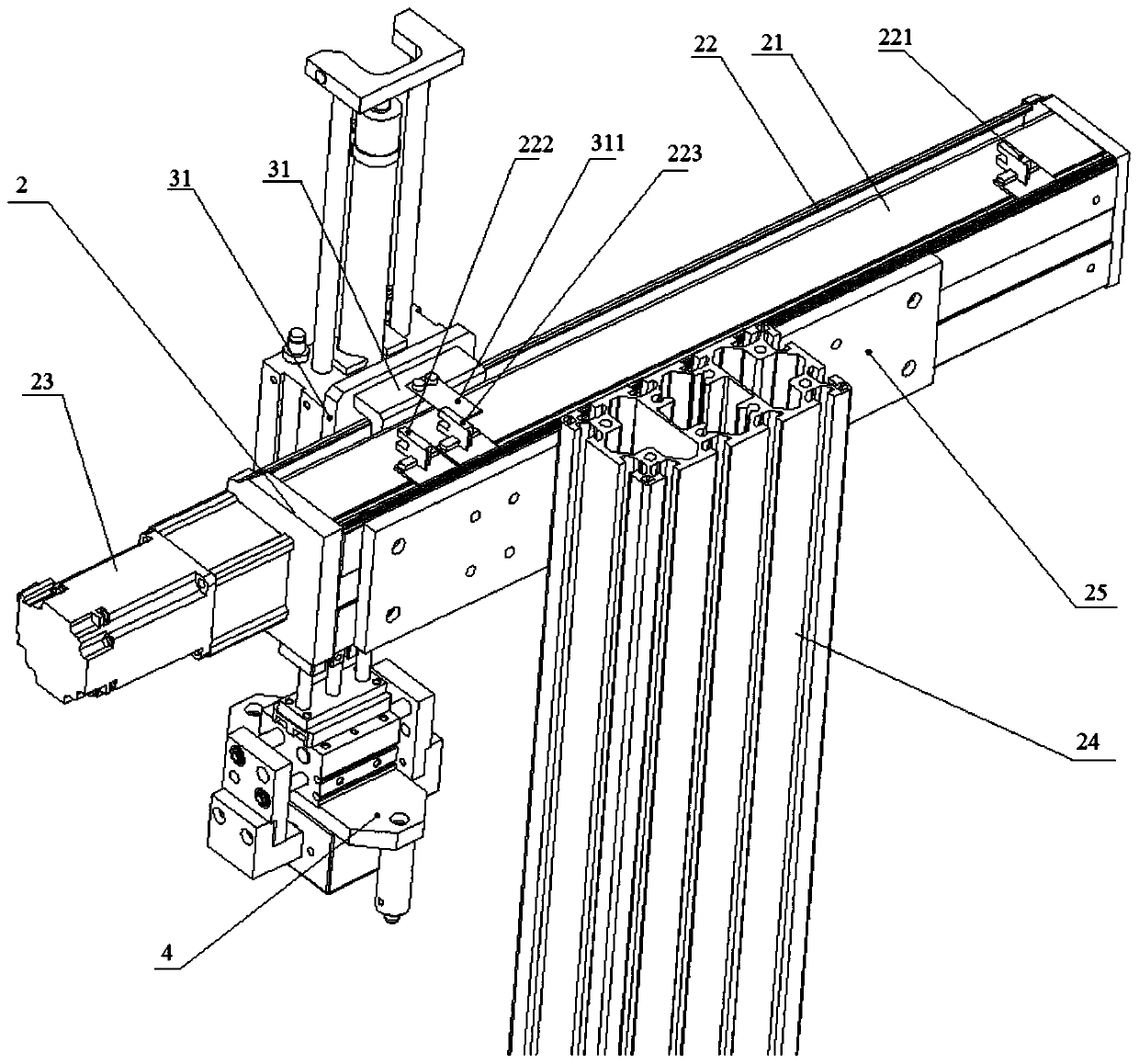

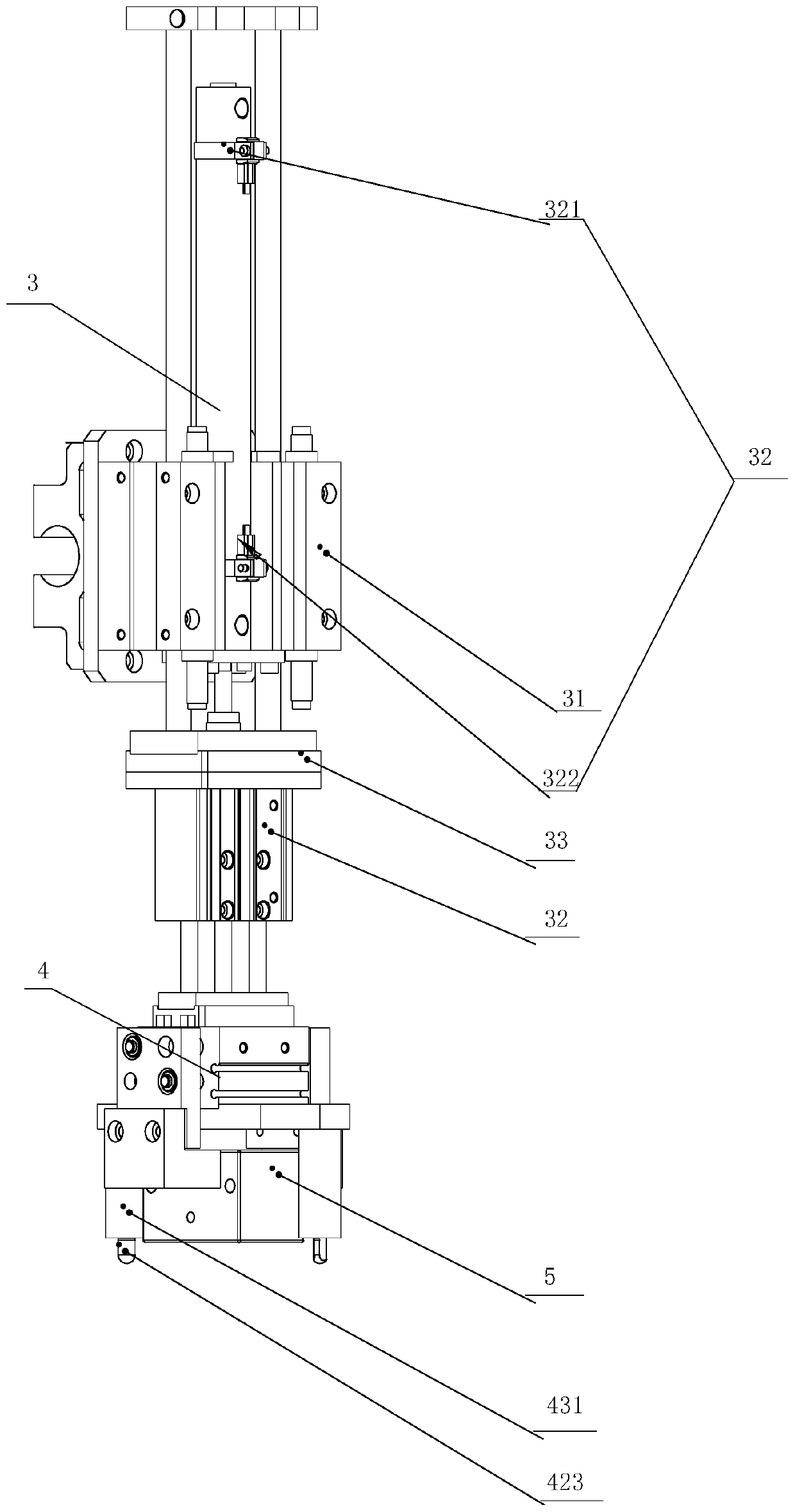

[0022] Figure 1 to Figure 4 A valve block automatic feeding mechanism shown includes a workbench 1, an advancing mechanism 2, a lifting mechanism 3 and a clamping mechanism 4, and the workbench 1 includes a rotating disk 11, a central fixed disk 12 and The angle divider assembly arranged in the workbench 1, the angle divider assembly drives the rotating disk 11 to rotate around the central fixed disk 12 fixed on the workbench 1, the forward mechanism 2 includes a forward and backward movement module 21 and a front and rear movement module 21 on the slide rail 22, the slide rail 22 is distributed with a front limit sensor 221, a rear limit sensor 222 and a discharge level...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com