Oiling ship cargo hold boil-off gas treatment and recovery method

A recovery method and evaporated gas technology, applied in chemical instruments and methods, separation methods, and dispersed particle separation, etc., can solve problems such as environmental pollution, cargo damage, and failure to recover and treat cargo hold evaporated gas, so as to reduce cargo damage and avoid pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The technical solution of this patent will be further described in detail below in conjunction with specific embodiments.

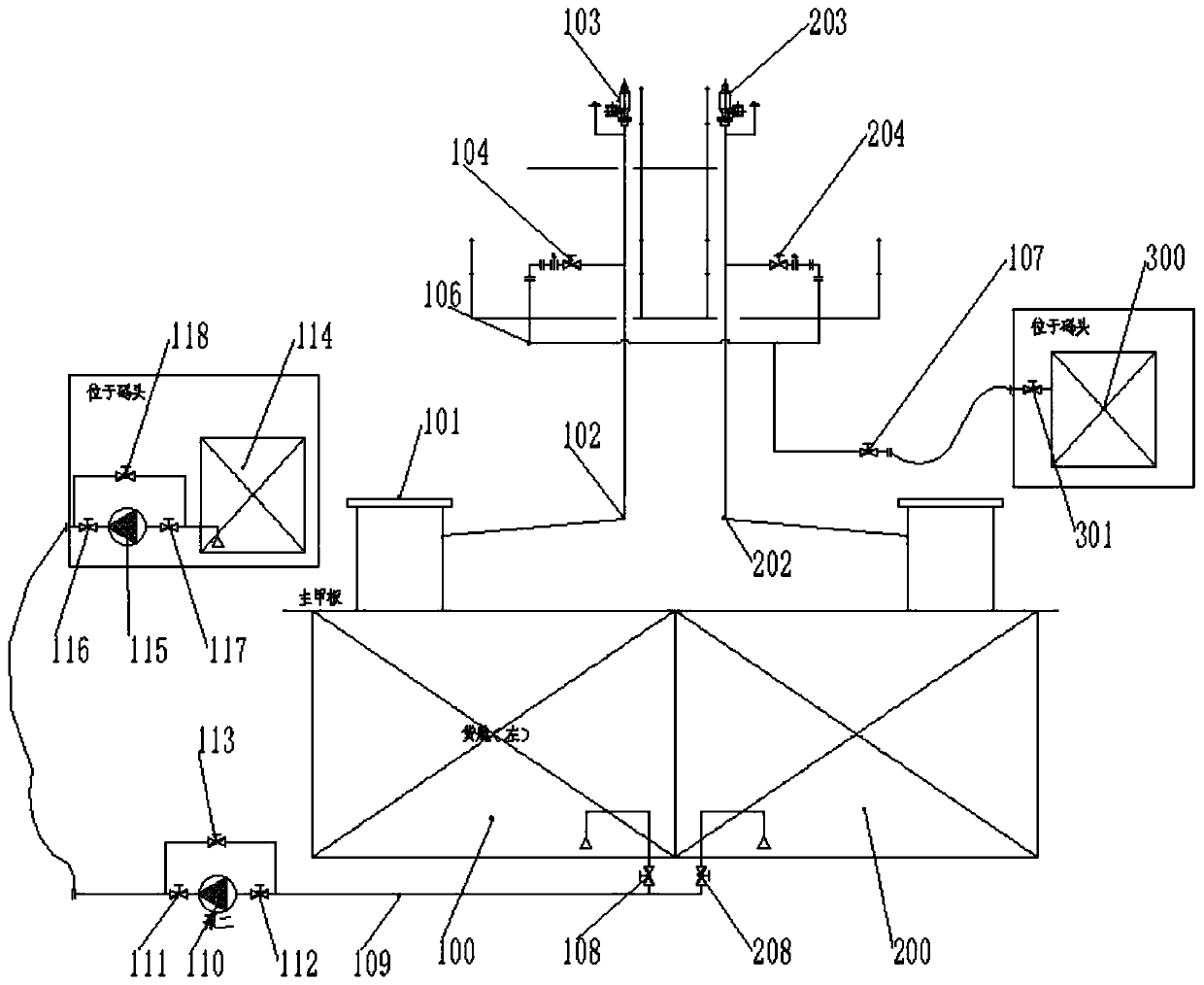

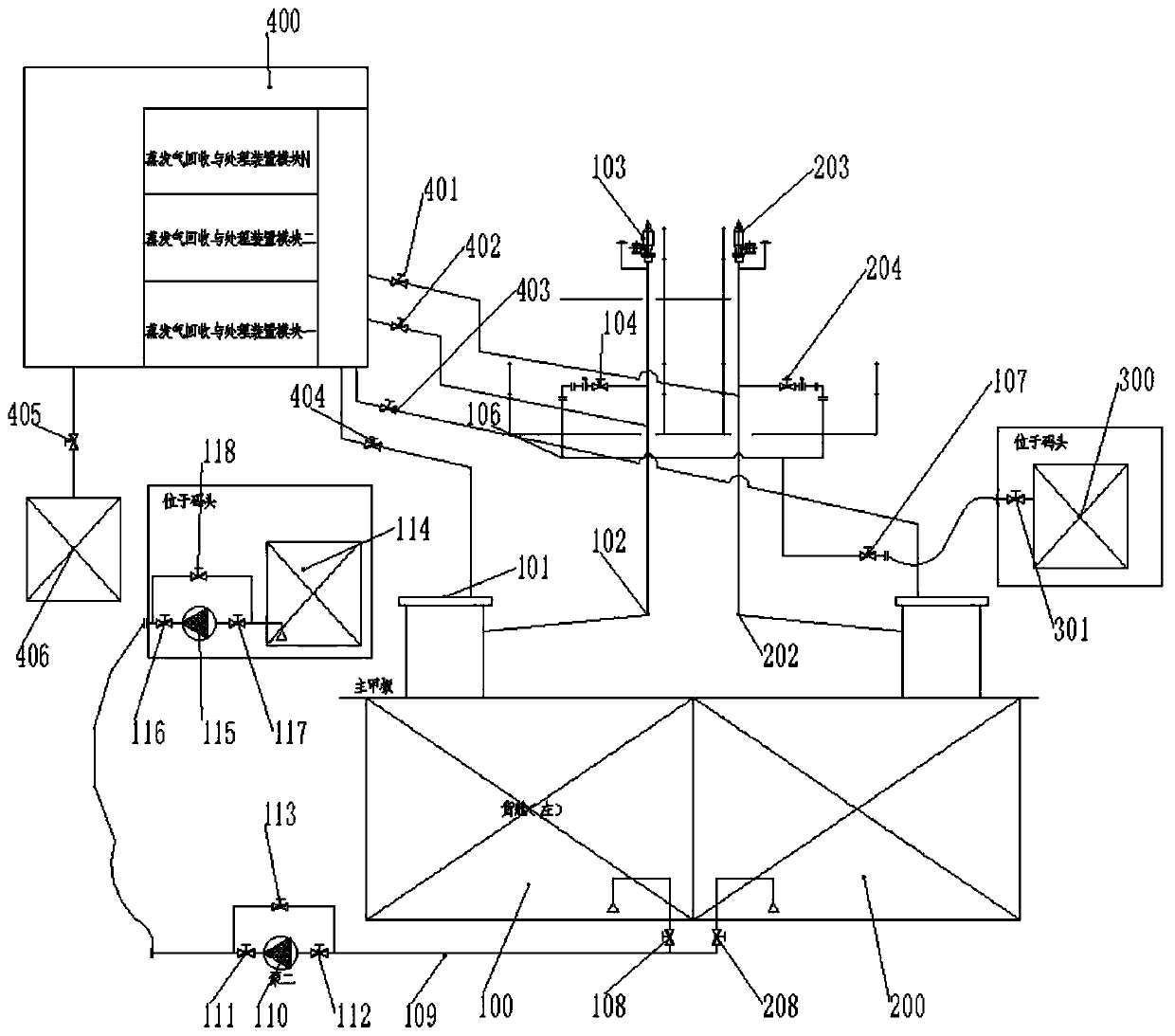

[0032] see figure 1 ,

[0033] In the prior art, the recovery and treatment technology of the evaporated gas of the oil and chemical ship, in the prior art, take two cargo holds on the oil and chemical ship as an example, for example, the cargo hold of the oil and chemical ship is left 100 and the cargo hold of the oil and chemical ship is right 200,

[0034] Cargo tank hatches 101 are provided on the top of the cargo tank 100 of the oil tanker and the right tank 200 of the tanker tank,

[0035] The hatches at the top of the cargo tank 100 of the oil and chemical ship and the right 200 of the cargo tank of the oil and chemical ship are respectively connected with a cargo tank ventilation pipe 1 102 and a cargo tank ventilation pipe 2 202 which are communicated with their respective inner cavities;

[0036] The ends of cargo hold ventilation pipe ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com