Furnace top sealing structure of suspended type heat treatment furnace

A heat treatment furnace and sealing structure technology, applied in the direction of furnace crown/roof, furnace, furnace components, etc., can solve the problems of poor temperature uniformity in the furnace cavity, decreased reliability of the production line, easy failure of lubricating oil and electric control systems, etc. To achieve the effect of suppressing the overflow of furnace gas and smooth transition action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

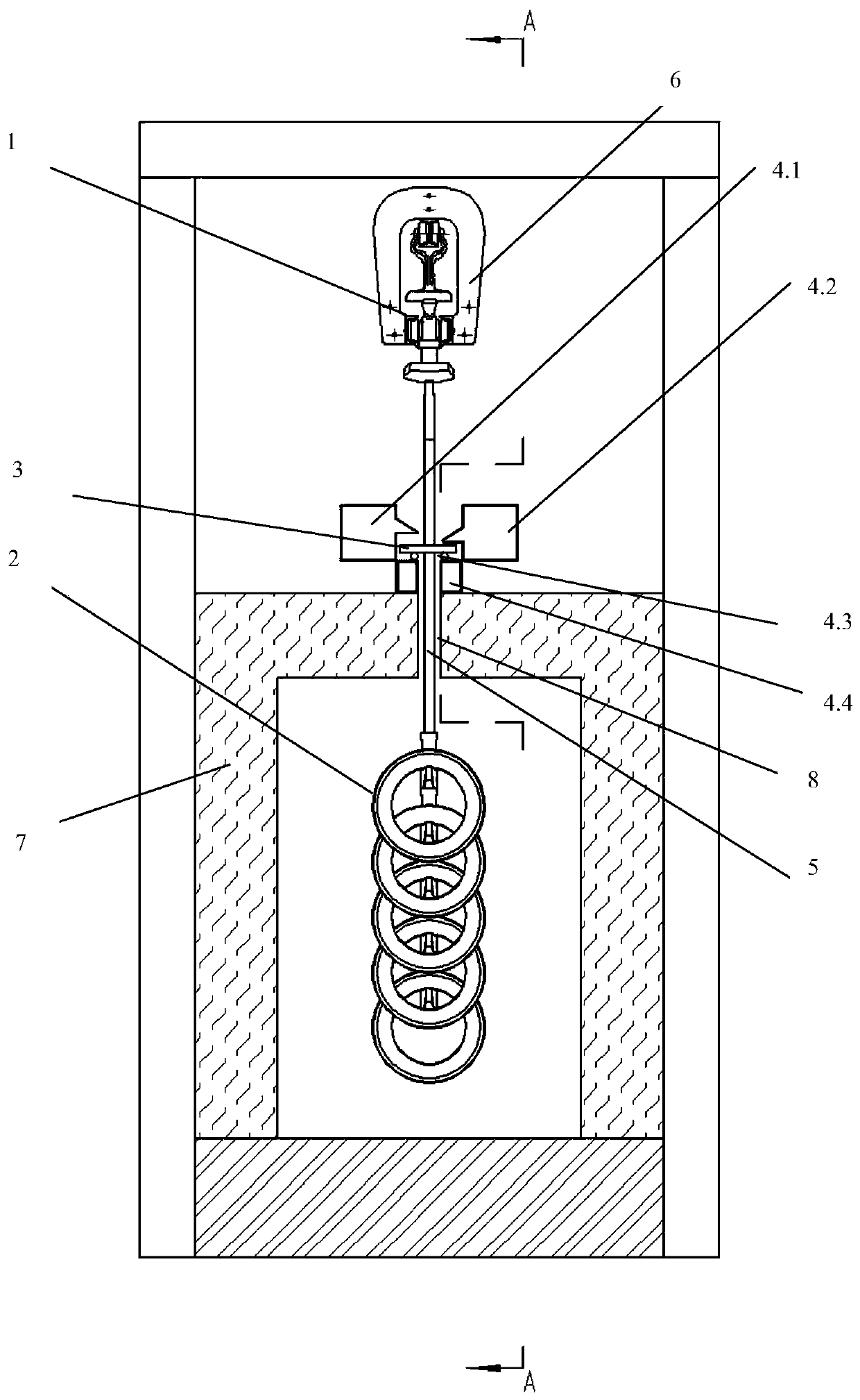

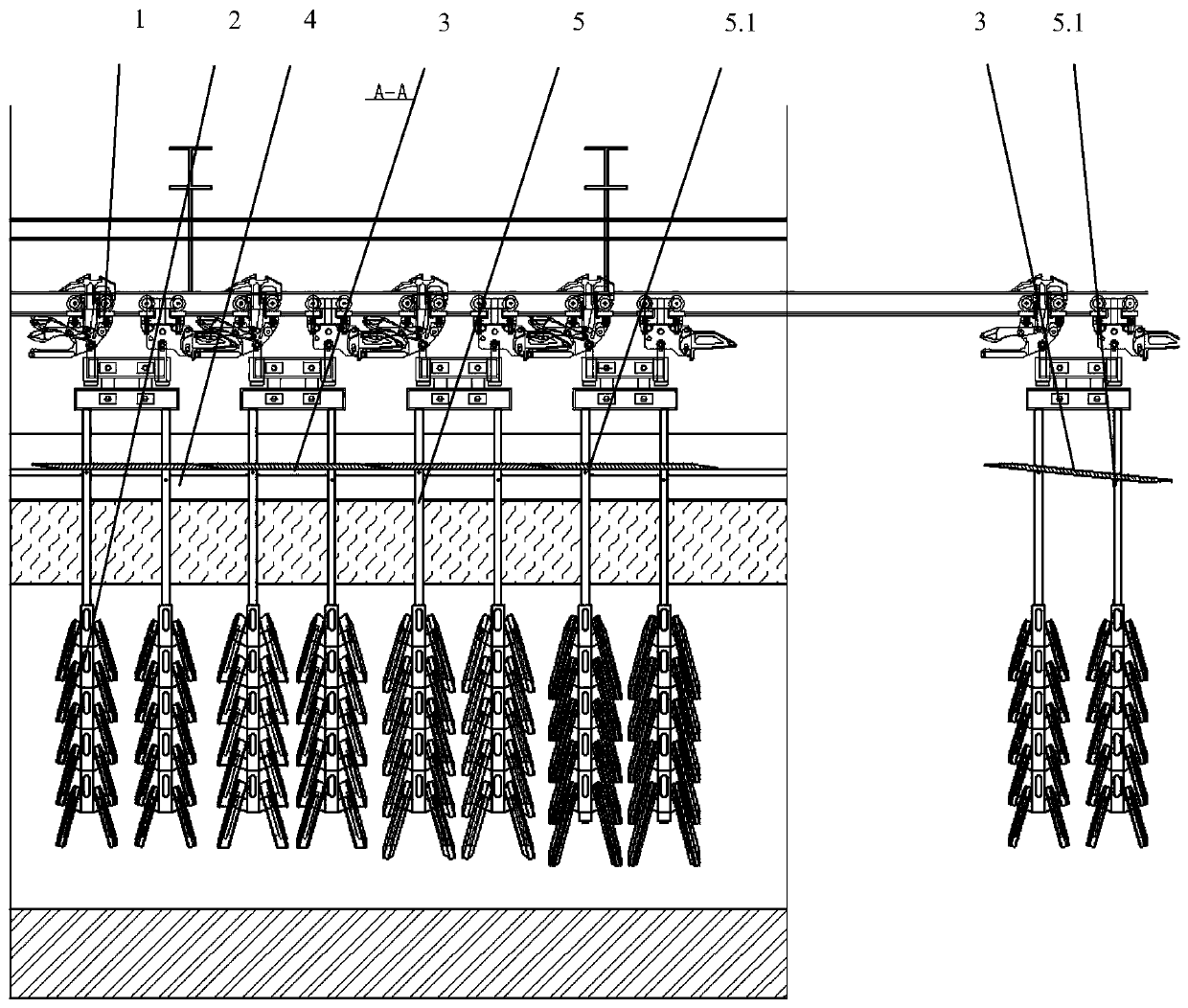

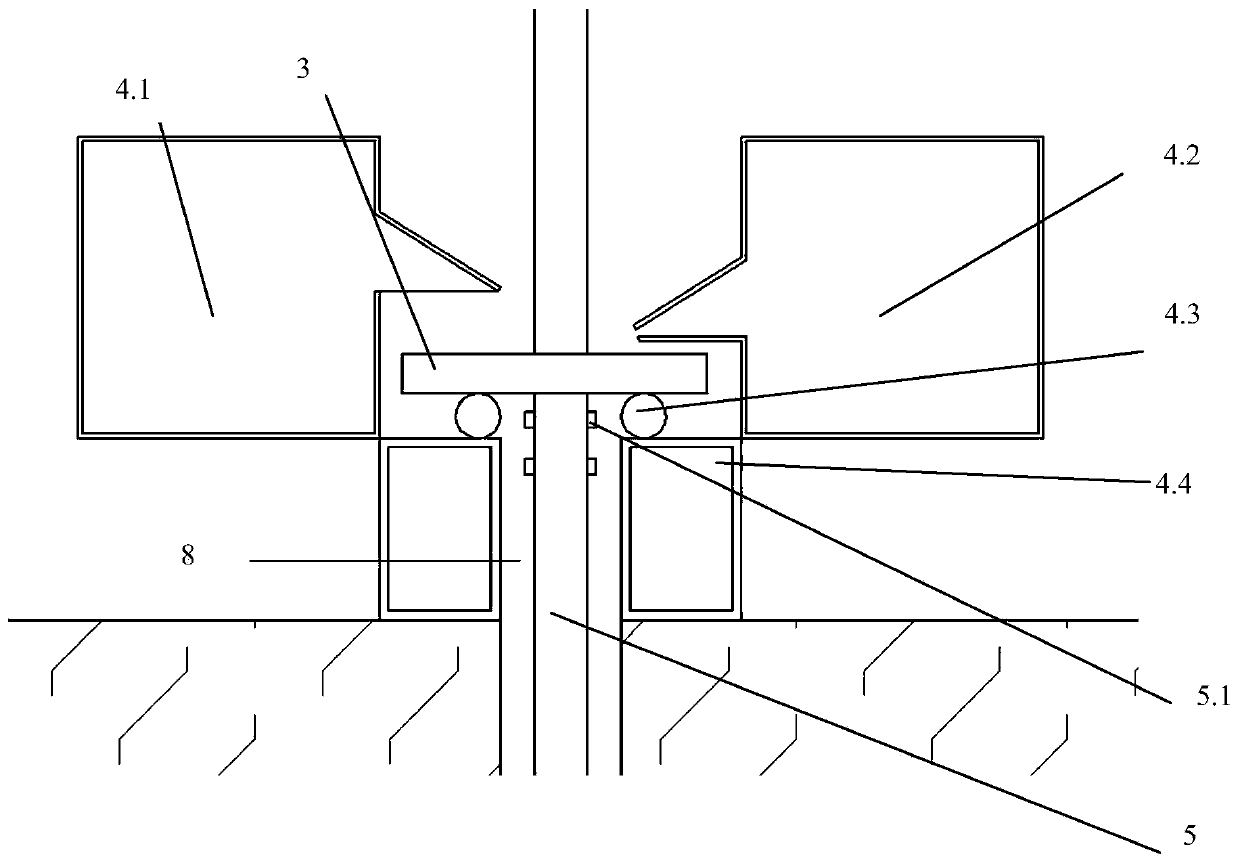

[0018] The roof sealing structure of the suspension heat treatment furnace provided by the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0019] Such as figure 1 — Figure 5 As shown, the suspended heat treatment furnace in the roof sealing structure of the suspended heat treatment furnace provided by the present invention mainly includes a circulating accumulation trolley track 6, multiple accumulation trolleys 1, a furnace body 7, at least one suspender 5 and A positioning tail rod 9; multiple groups of accumulating trolleys 1 are arranged on the circular accumulating trolley track 6 in a manner that can move along the circulating accumulating trolley track 6; At a certain part, a long seam 8 is formed in the middle of the top surface along the moving direction of the accumulating trolley 1; the upper ends of multiple suspenders 5 or one suspender 5 and a positioning tail bar 9 are connected to a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com