Fixing structure of hanging hole cover of cabin cover

A technology for covering hanging objects and nacelle covers, which is applied in the direction of building structures, building fastening devices, engines, etc., which can solve the problems of hidden safety hazards, difficult operation, and loss of operators, so as to reduce the risk of operators, quickly open or Closed, simple and compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

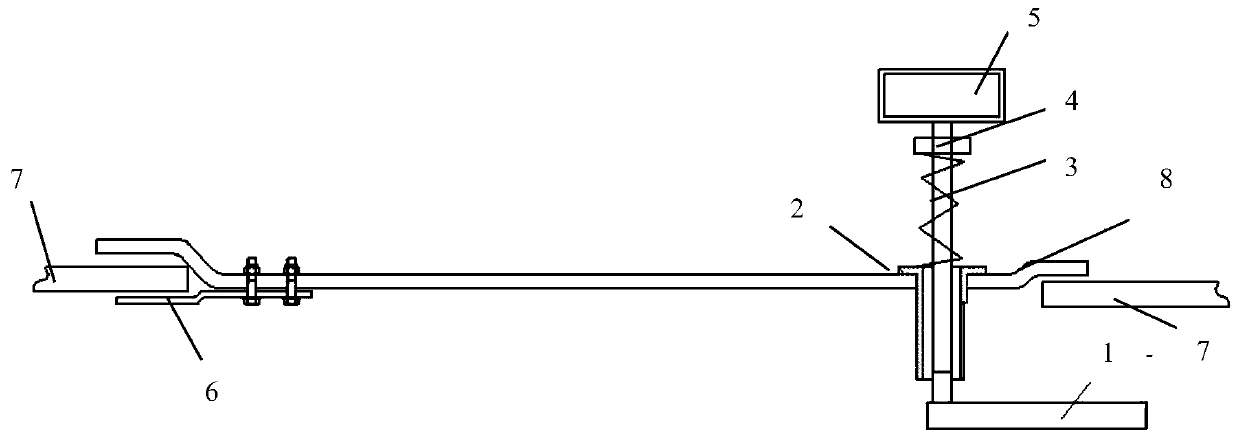

[0018] In order to better understand the purpose, structure and function of the present invention, a nacelle cover hanger hole cover fixing structure of the present invention will be further described in detail below in conjunction with the accompanying drawings.

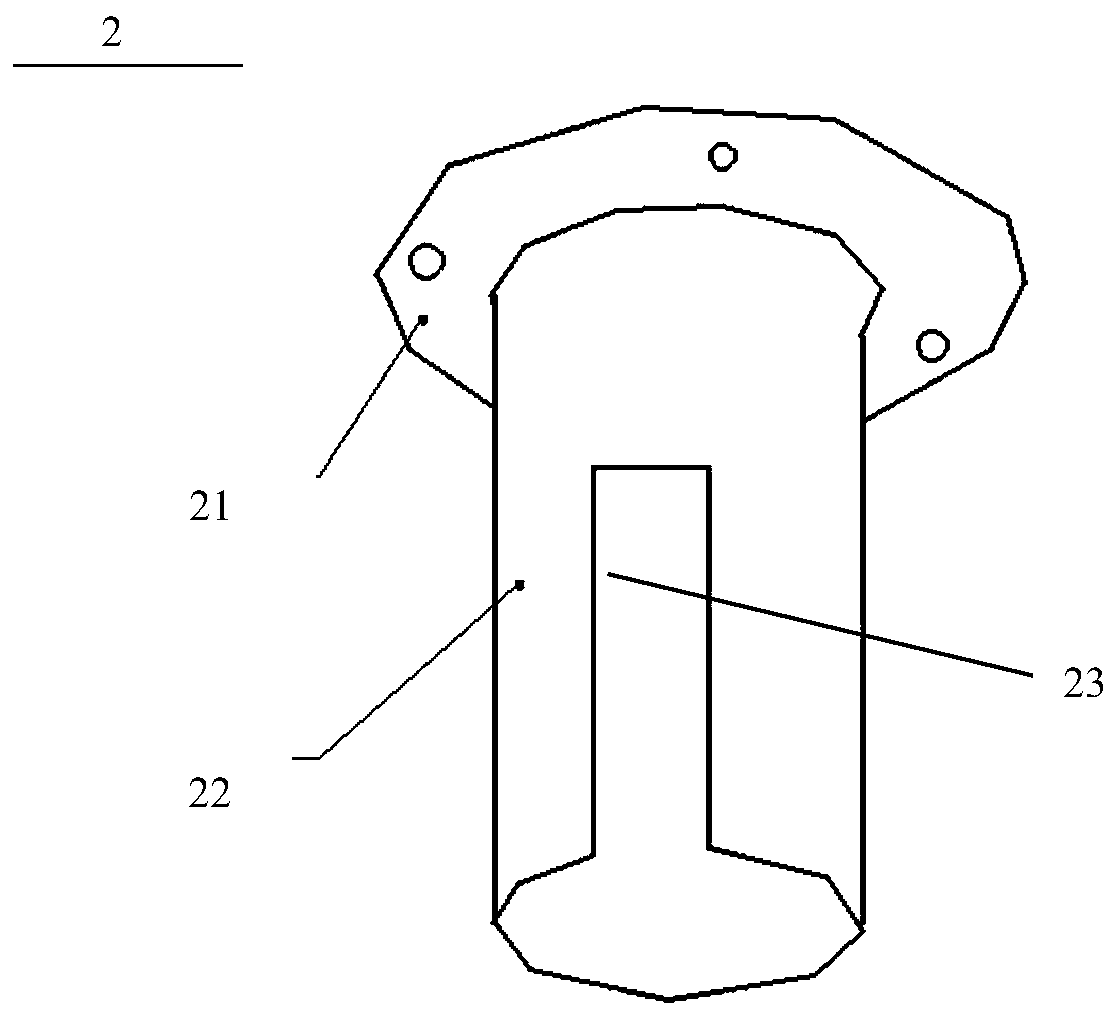

[0019] Such as Figure 1 to Figure 2 As shown, it is shown as a fixing structure for the hanging object hole cover of the nacelle cover of the present invention, including L-shaped bolts 1 and sleeves 2, wherein the sleeve 2 includes integrally formed fixing flanges 21 and cylindrical tubes 22, fixedly arranged On the edge of the inner surface of the hanging object hole cover 8, the cylindrical tube 22 is arranged near the outside of the nacelle cover, and the cylindrical tube 22 is longitudinally provided with a groove 23; the L-shaped bolt 1 includes an integrally formed stud and a chuck, and the chuck is used For fastening the nacelle cover, the L-shaped bolt 1 is sleeved in the cylindrical tube 22 of the sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com