Tower-shaped fermenter and application method thereof

A fermentation tank and tower technology, applied in the field of organic fertilizer fermentation treatment, can solve the problems of unsmooth blanking, enlargement, clogging power consumption, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

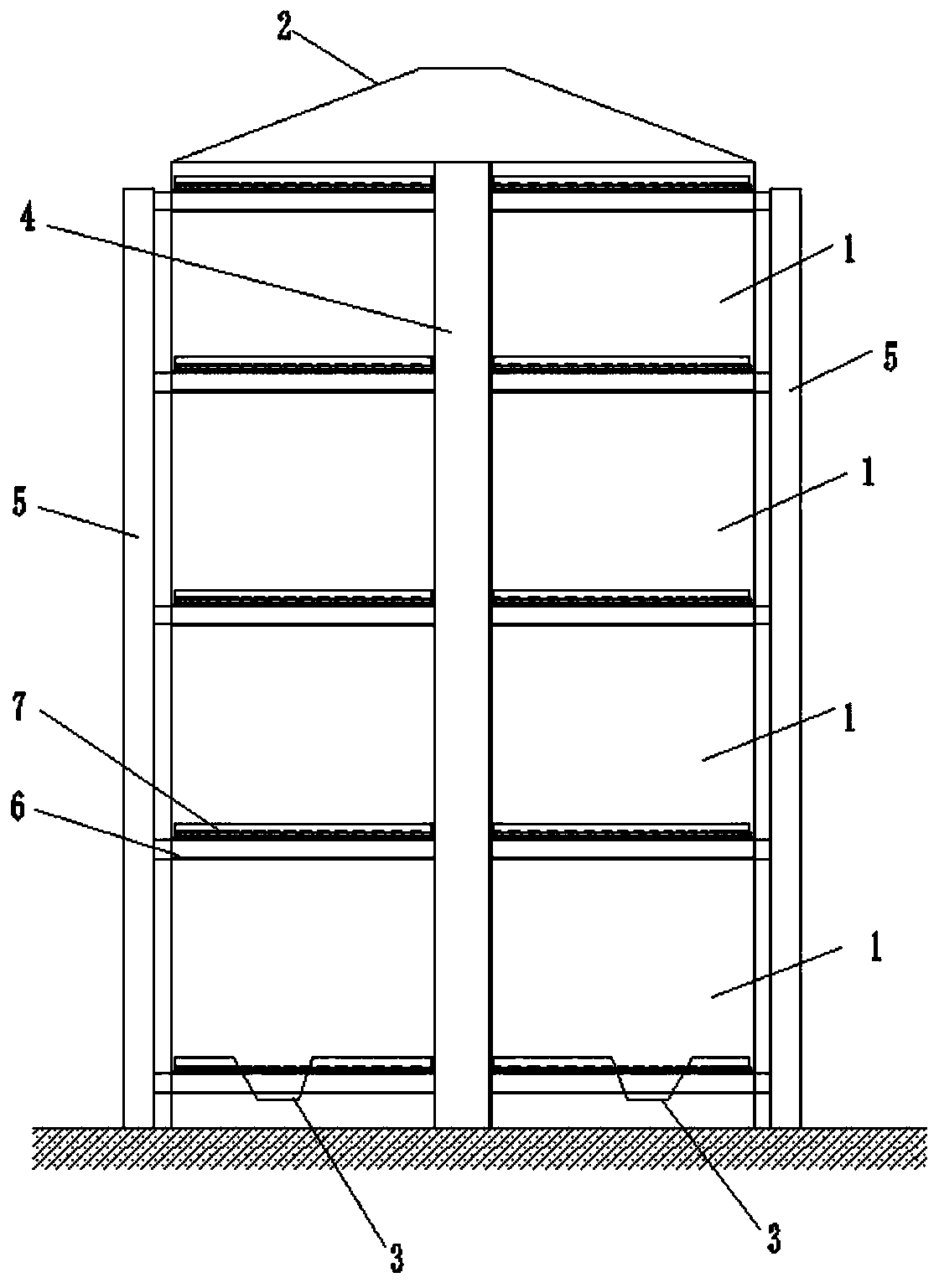

[0049] A fermenter of the present invention, such as figure 1 As shown, the tank body of the mixing tank is a vertical four-layer silo, which is spliced by stainless steel plates and steel plates to store materials, with a diameter of 8 meters to 20 meters and a height of 10 meters to 20 meters. Between the silos, riveting is used to connect the plates of the silo and sealing strips are added to prevent water seepage. Insulation cotton is added in the middle for heat preservation, and galvanized steel sheets are used on the outside for protection.

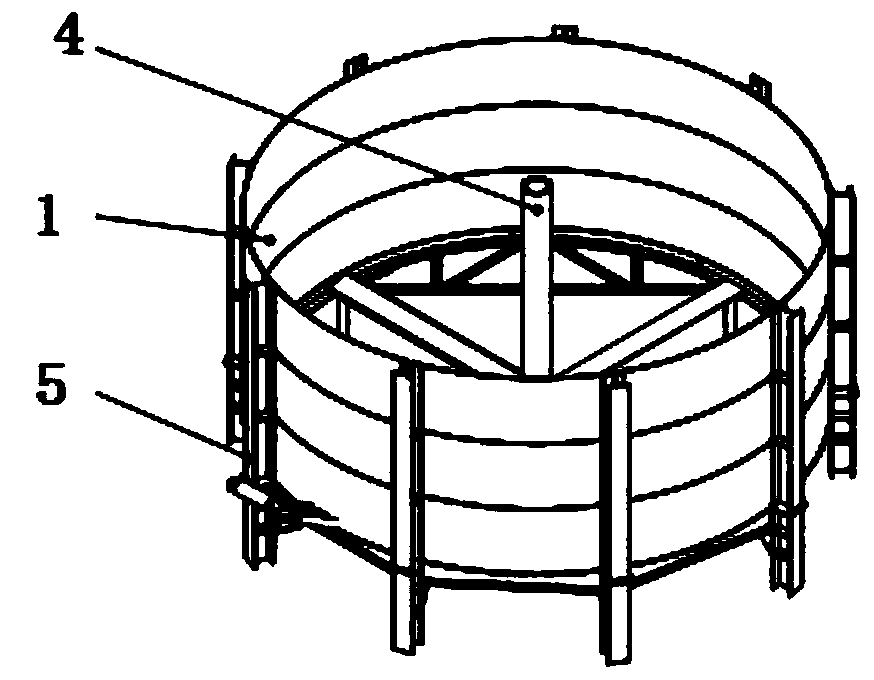

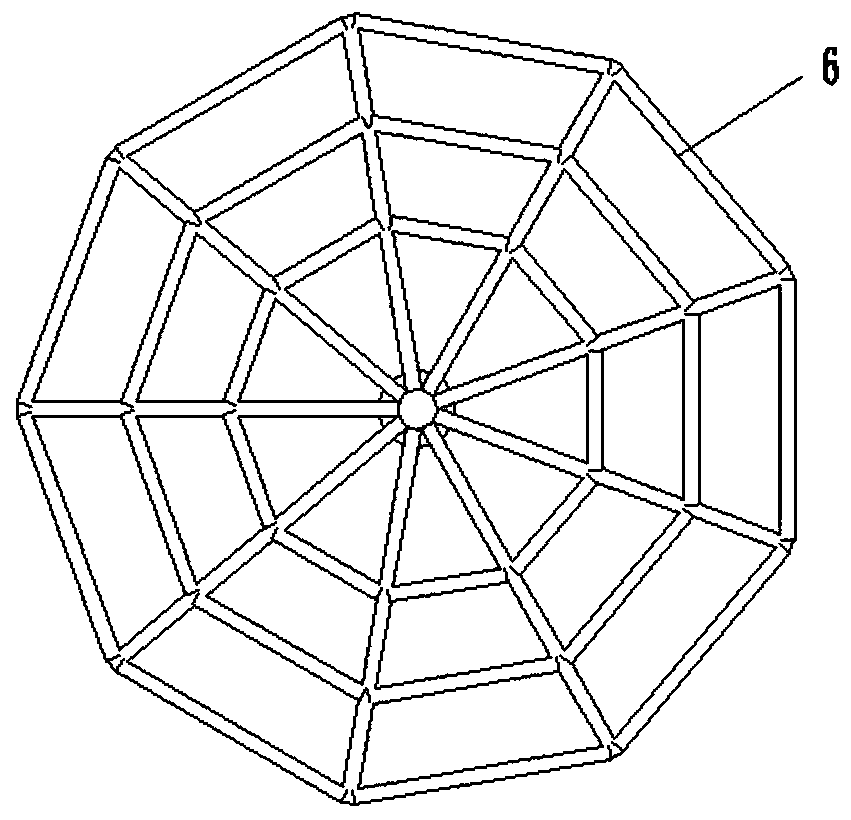

[0050] There are 3 layers of layering devices in the middle of the tank, and each layer of layering devices includes a chassis 6 and an agitating plate 7. The chassis 6 is connected by pipes from the middle and the outer column 6 on the periphery to support the materials in the warehouse. A stirring plate 7 is arranged above each chassis 6, and the edge of the stirring plate 7 maintains a gap of 5-15 centimeters with the outer wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com