Method for optimizing the repair of local casting defects on inner and outer surfaces of pump bodies

A technology for internal and external surfaces and casting defects, which is applied in the direction of detecting the appearance of fluid at the leakage point, using liquid/vacuum degree for liquid tightness measurement, sorting, etc., which can solve the inaccurate detection of the pump body and the low efficiency of the pump body detection and other problems, to achieve the effect of improving the stability of placement, improving the stability of movement, and reducing the impact of steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

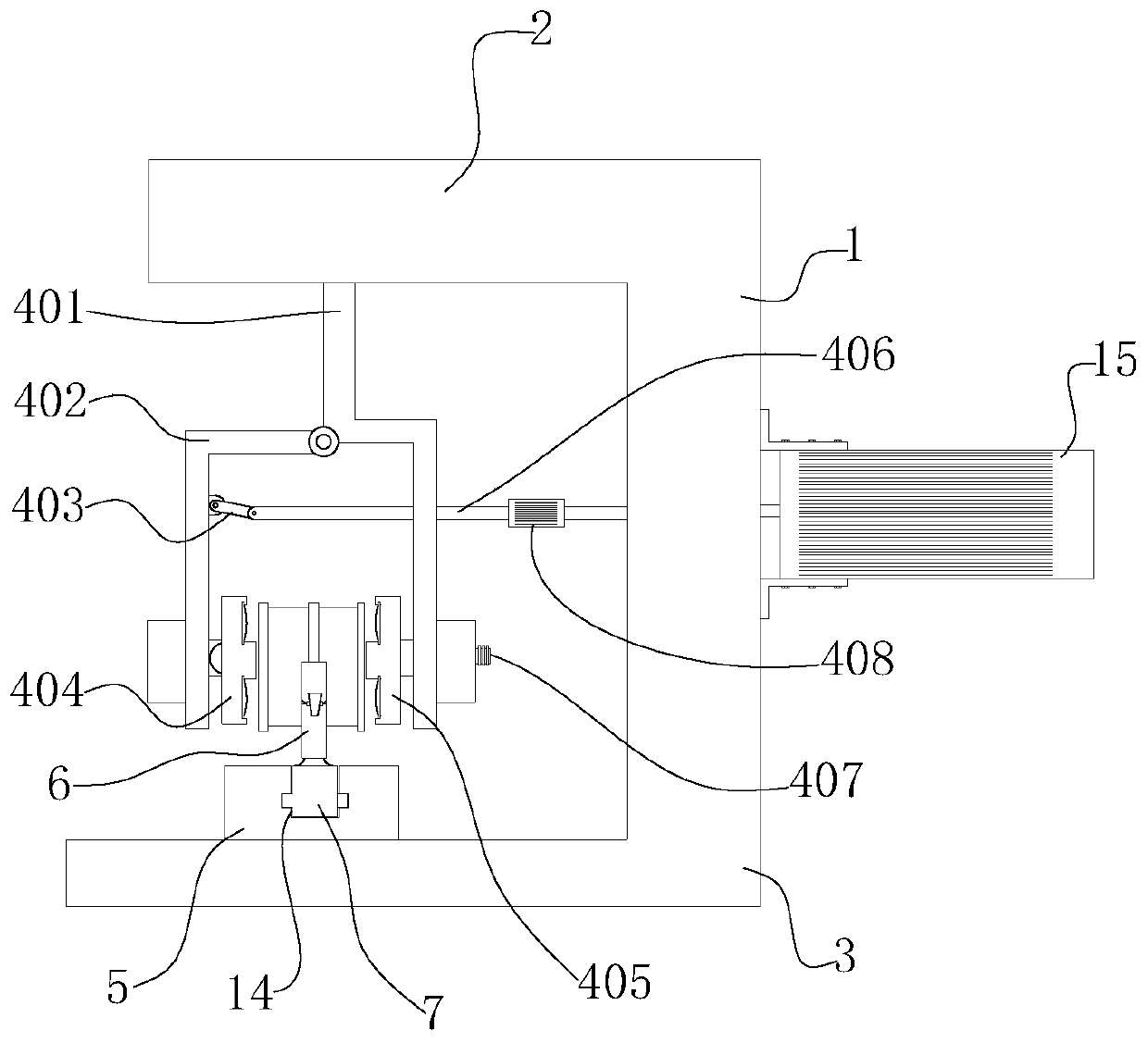

[0043] see figure 1 , figure 2 , Figure 6 and Figure 7 , is a schematic diagram of the overall structure of an optimization method for repairing local casting defects on the inner and outer surfaces of the pump, including the following steps:

[0044] S1. Appearance inspection of the pump body. The outer surface of the pump body is detected by manually rotating the pump body repeatedly, and the outer surface of the pump body is observed with the naked eye; the pump body with holes and cracks on the outer surface of the pump body is screened out.

[0045] S2. Store separately, store the pump body with cavities and cracks on the surface and the pump body with a good surface in step S1 separately, and wait for the defect repair in the later stage;

[0046] S3. Inspection of the inner cavity of the pump body. Use a sealing detection device to fill the inner surface of the pump body with fluid into the flow channel of the pump body, seal it for 8 seconds, observe whether ther...

Embodiment 2

[0060] see Figure 1-7 , is a schematic diagram of the overall structure of a method for repairing and optimizing local casting defects on the inner and outer surfaces of the pump body. This embodiment has similarities with the above-mentioned embodiment 1, and the similarities will not be described in this embodiment. The specific differences in:

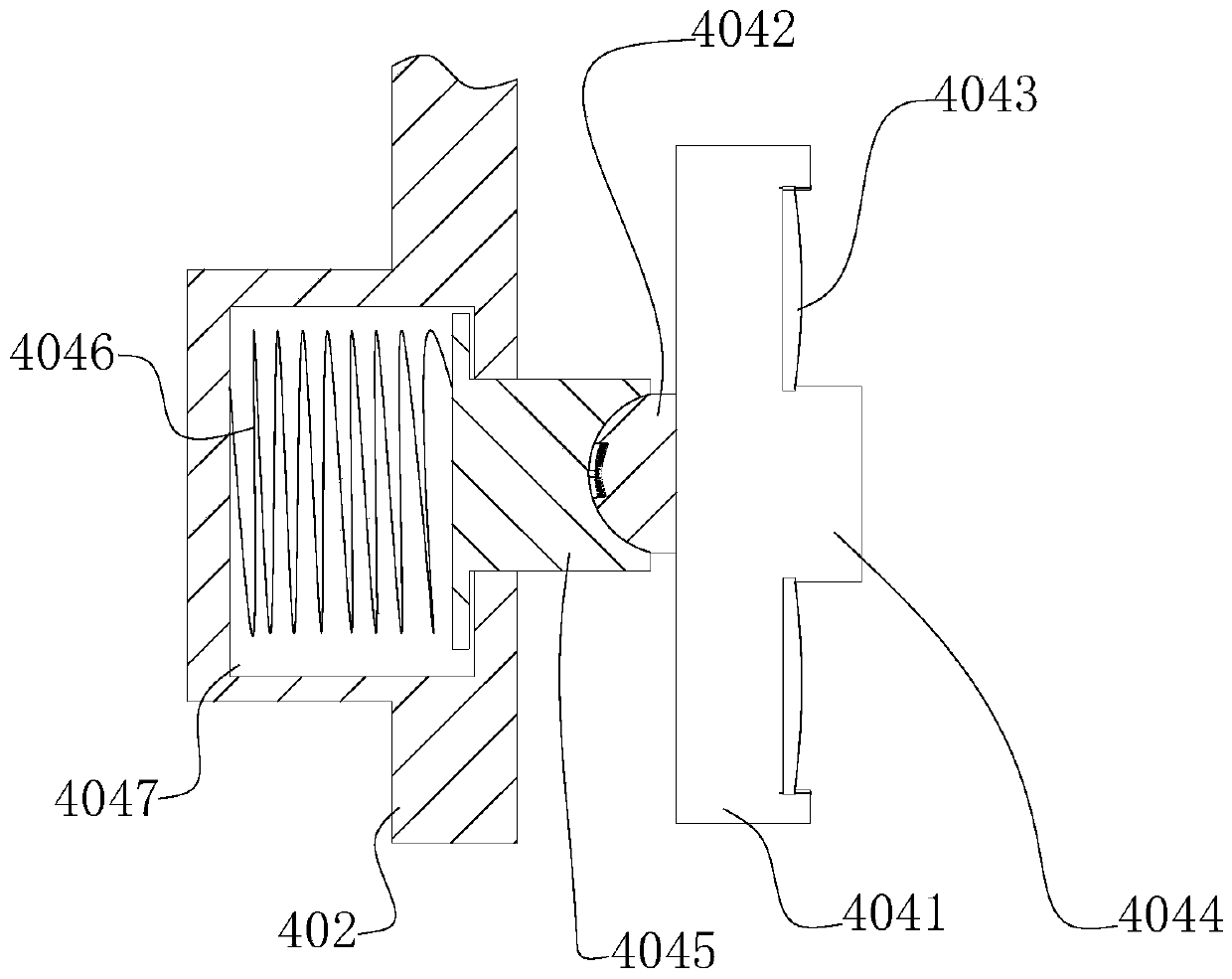

[0061] The sealing fixture 4 includes a fixed support plate 401 and a movable support plate 402, the fixed support plate 401 is fixedly installed on the bottom end of the top support plate 2, the fixed support plate 401 is set as a square plate, and the middle of the fixed support plate 401 is provided with a through circle holes, the second sealing disk 405 is fixed at the bottom of the fixed support plate 401 at equal intervals;

[0062] The outer wall of the fixed support plate 401 is hinged with a movable support plate 402 close to the bottom end of the top support plate 2, so that the movable support plate 402 and the fixed s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com