Online rotary ferrograph and equipment oil online monitoring method

A ferrography and rotary technology, applied in the field of ferrography analysis, can solve the problems of difficult cleaning, complicated operation process, blurred edges of abrasive grain images, etc., and achieve the effect of increasing deposition area, clear abrasive grain images, and good observation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

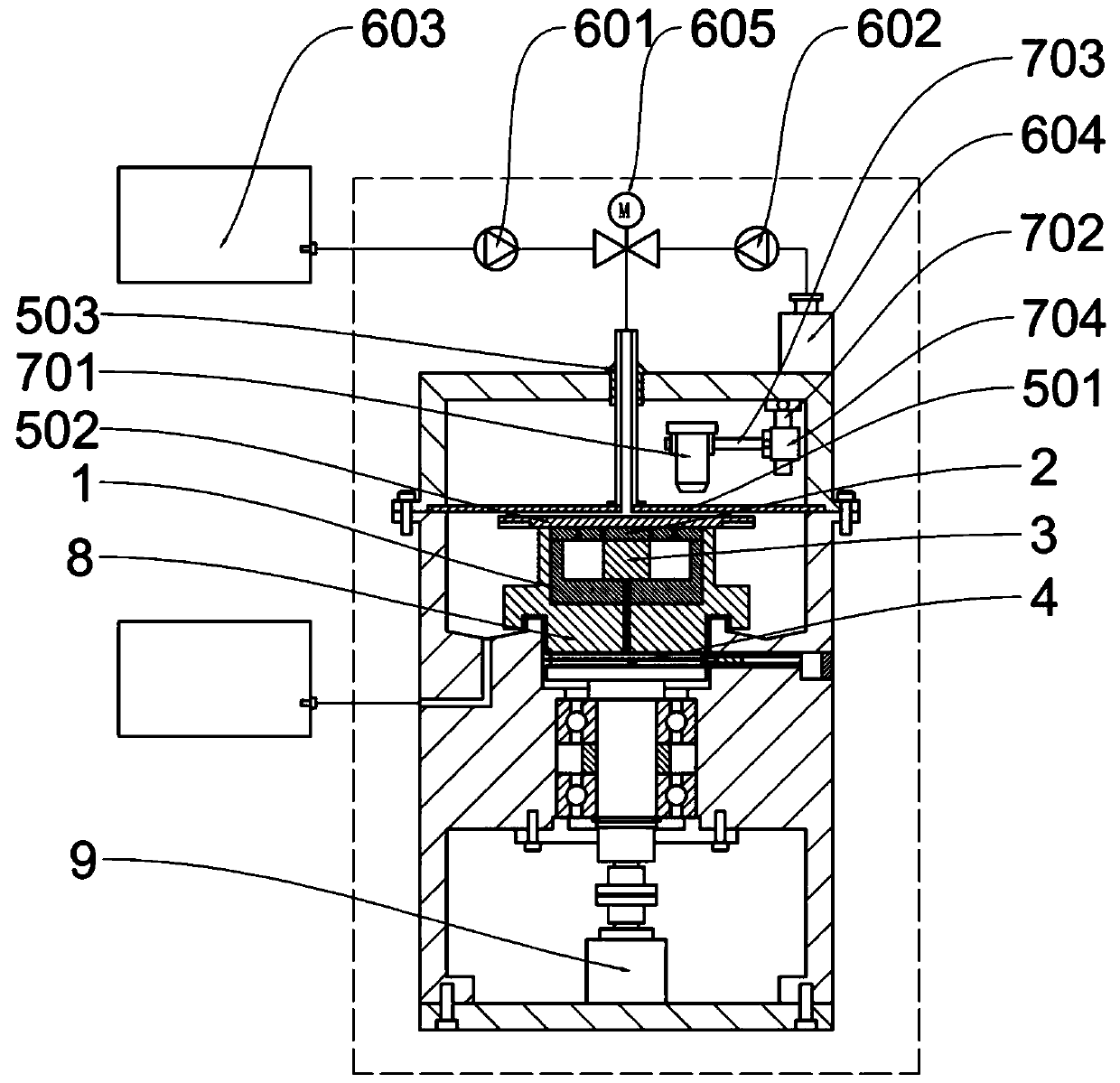

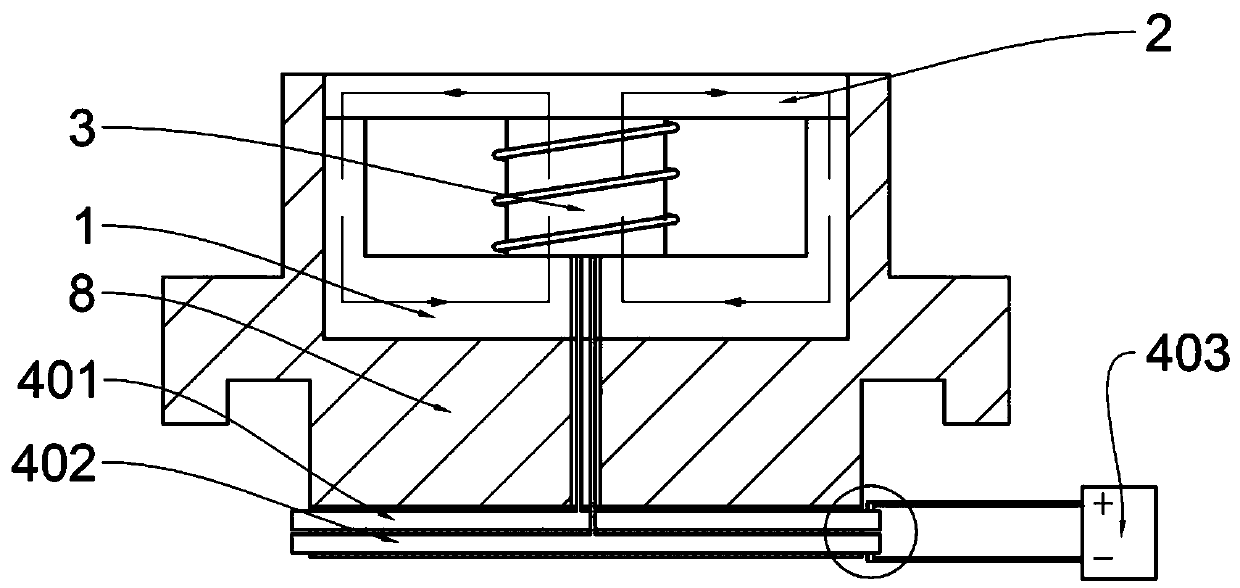

[0035] The invention provides an on-line rotary ferrography instrument, which includes an abrasive particle deposition spectrum forming module and a magnetic head module.

[0036] The magnetic head module includes a rotatable magnetic head; the magnetic head includes a cylindrical magnetic bottom block 1, a pole shoe 2 that is connected to the upper opening of the magnetic bottom block 1 and is located at the axis of the magnetic bottom block 1. An electromagnet column 3; one end of the electromagnet column 3 is connected to the bottom surface of the magnetic bottom block 1, and the other end is connected to the pole shoe 2 to form a closed magnetic circuit;

[0037] The magnetic head module also includes a magnetic head housing 8 fixedly wrapped on the outside of the magnetic bottom block 1 ; it also includes a stepping motor 9 for driving the magnetic head to rotate; the rotating shaft of the stepping motor 9 is connected to the magnetic head housing 8 .

[0038] The magneti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com