Efficient target correcting lens axis consistency calibration device and method

A verification device and consistent technology, applied in the direction of aiming devices, weapon accessories, offensive equipment, etc., can solve the problems of difficult adjustment, low installation efficiency, and long time consumption, and achieve simple installation and adjustment structure, high installation and adjustment efficiency, and installation The effect of high tuning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The preferred modes of the present invention will be further described in detail below in conjunction with the accompanying drawings.

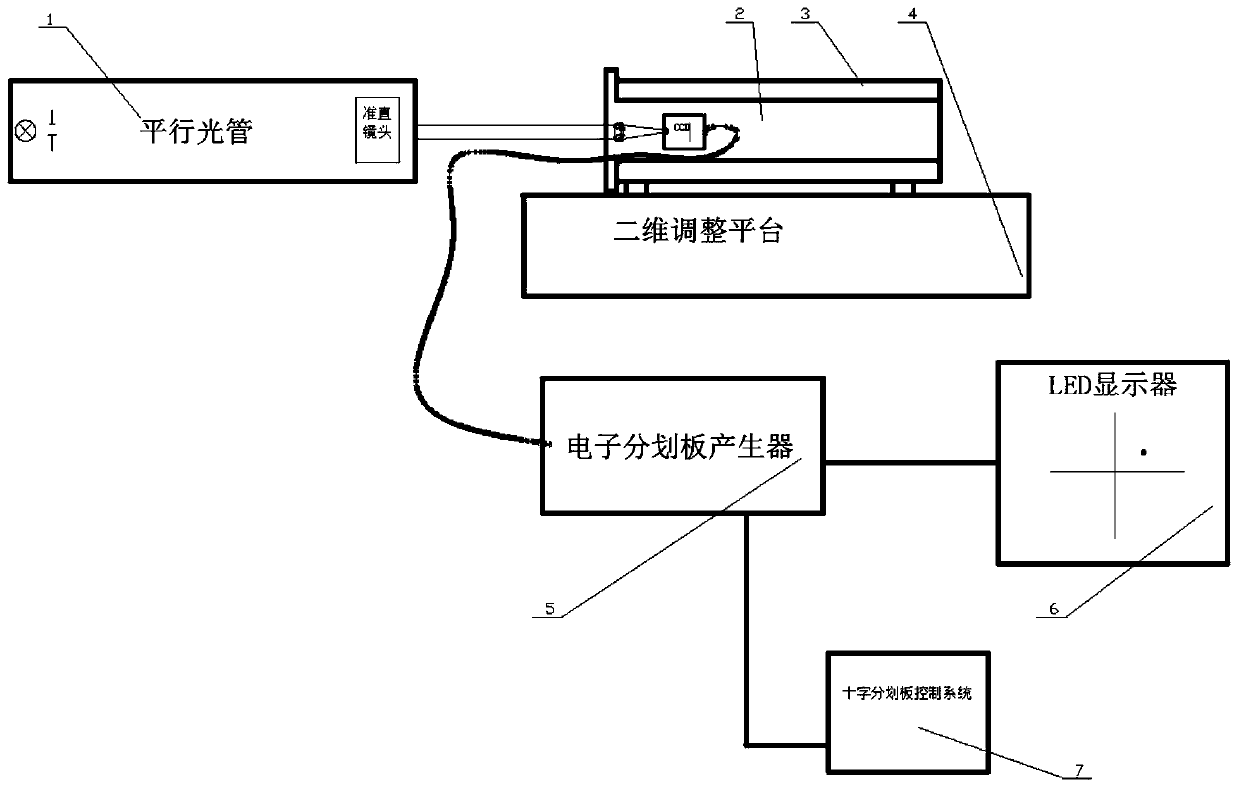

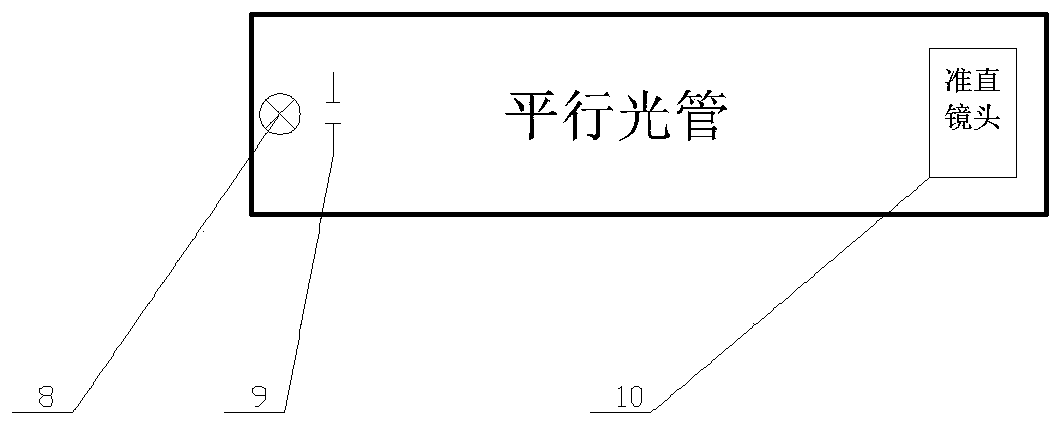

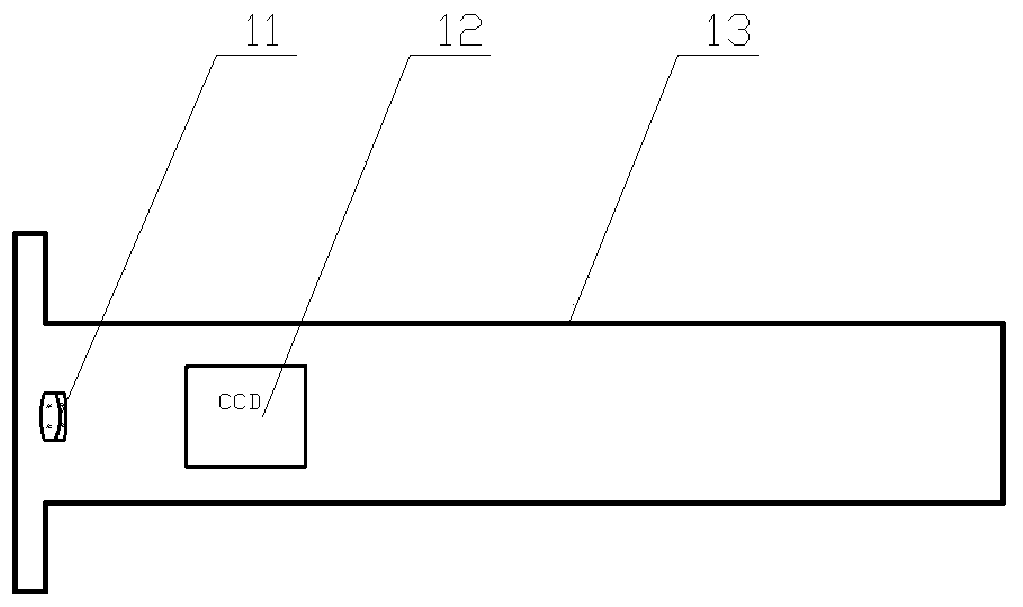

[0028] see figure 1 , figure 2 and image 3 , a high-efficiency target calibration mirror axis consistency verification device of the present invention, including a two-dimensional azimuth adjustment table 4, and a cylinder 3 installed on the adjustment table, the target calibration mirror 2 to be checked is installed inside the cylinder, and the collimator 1 The emitted parallel light fills the aperture 11 of the objective lens of the target lens to be checked. The CCD 12 inside the target calibration mirror transmits the collimator star point image to the electronic cross reticle generator 5, processes it through the computer terminal control system 6, and displays on the LED display 7:

[0029] The adjustment table is a two-dimensional azimuth adjustment table 4, including the adjustment of pitch and yaw.

[0030] In the electro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com