Vibration-isolation foot pad applied to air conditioner compressor

An air-conditioning compressor and compressor technology, which is applied in the direction of shock absorbers, mechanical equipment, shock absorber-spring combinations, etc., can solve the problems of low matching efficiency between testing and design, difficulty in matching and selecting foot pads, and non-adjustable stiffness, etc. problems, achieve good environmental friendliness, reduce installation and disassembly time, and improve accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

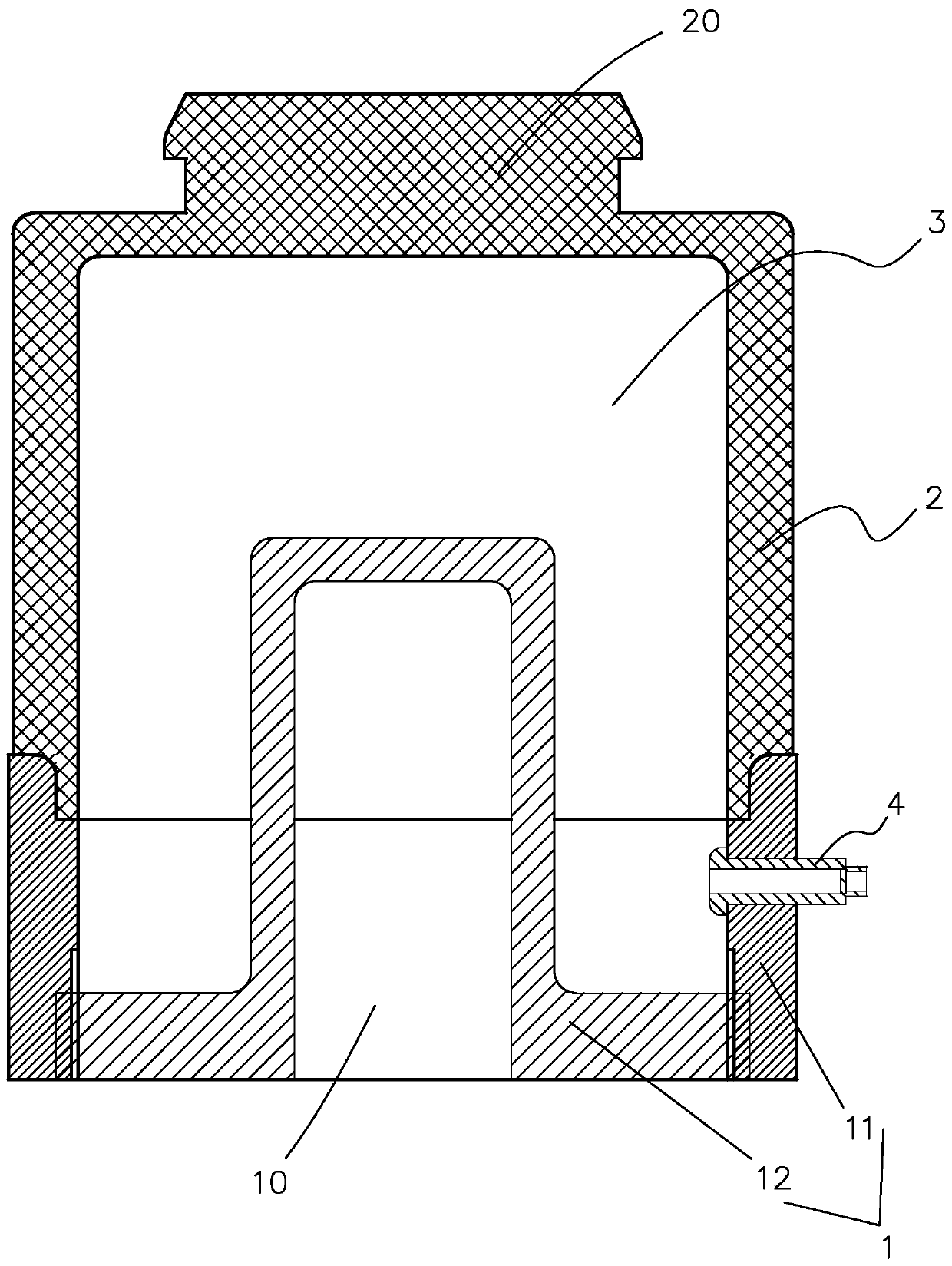

[0021] A vibration isolation foot pad for an air conditioner compressor, comprising a rigid base 1 used to connect with the bottom plate of the air conditioner, and a rubber member 2 sealed to the top of the rigid base 1 for connecting with the bottom of the compressor. A closed space 3 is formed between the piece 2 and the rigid base 1, and the side of the rigid base 1 is provided with an air nozzle 4 for inflating or deflating the closed space 3.

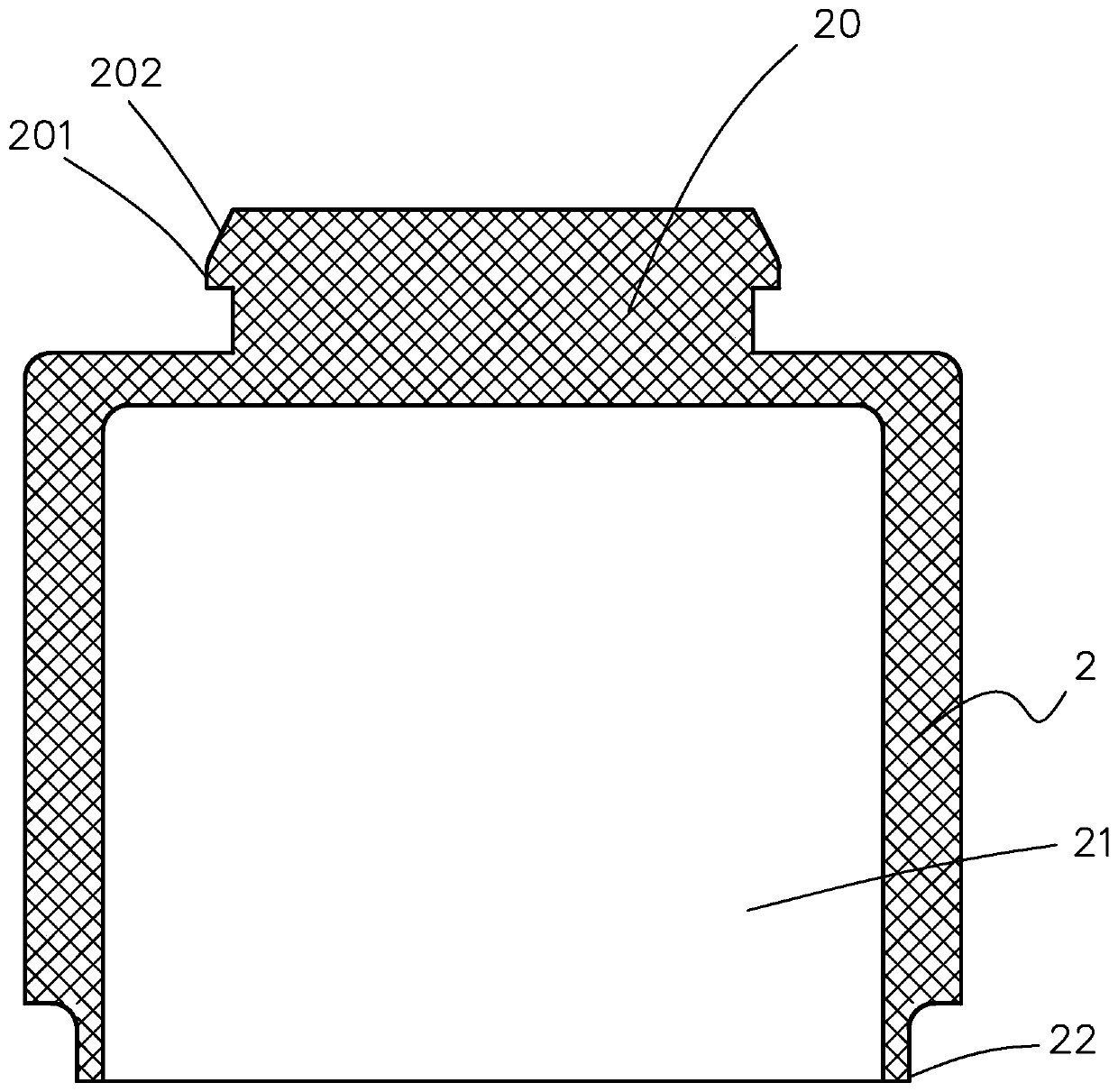

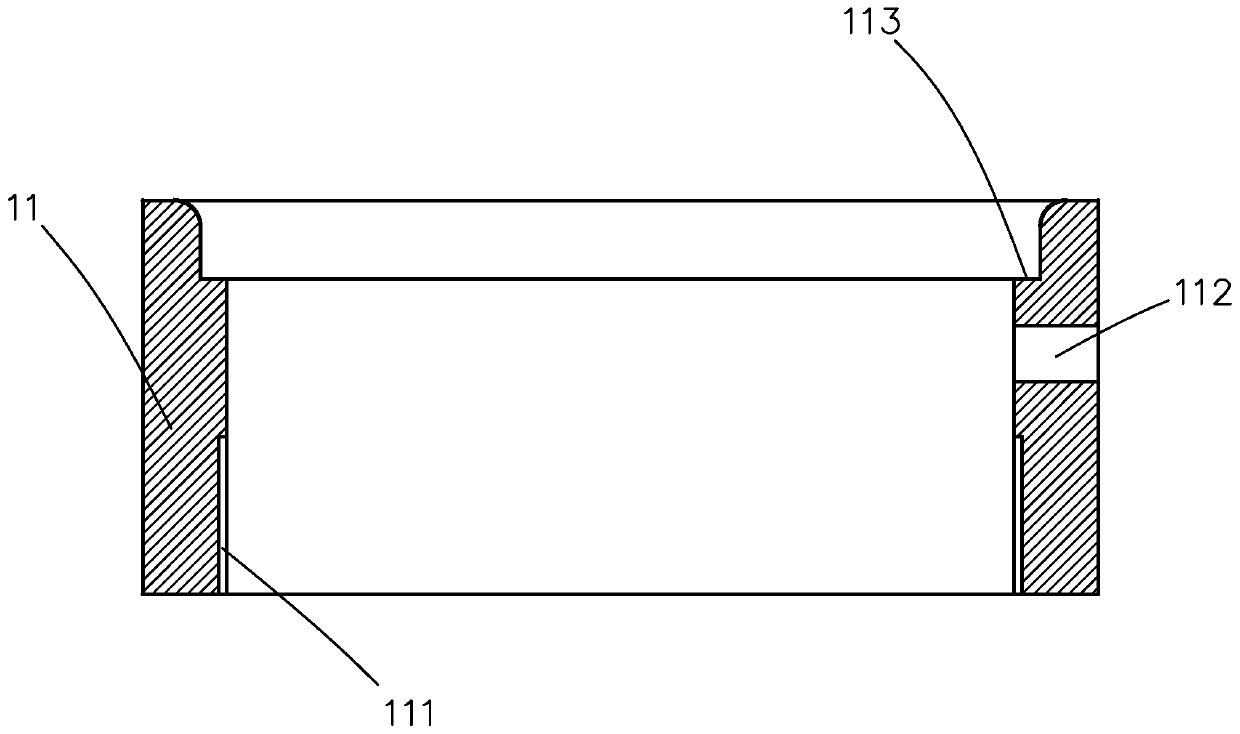

[0022] In order to optimize the connection between the vibration isolation foot pad and the compressor, and make the connection between the vibration isolation foot pad and the compressor and the bottom plate simple and reliable, the top of the rubber piece 2 is provided with a clamping protrusion 20 for connecting with the bottom of the compressor, a rigid base The bottom of 1 is provided with a connecting hole 10 for connecting with the bottom plate of the air conditioner. In order to further facilitate the connection and improve t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com