Vibration damping device, suspension and suspension stiffness control method

A vibration damping device and mounting technology, which is applied to power plants, jet propulsion devices, internal combustion propulsion devices, etc., can solve the problems of inability to apply amplitude, poor impact effect, and inability to actively adjust the stiffness of the mounting device, and achieve rapid The effect of the active vibration reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

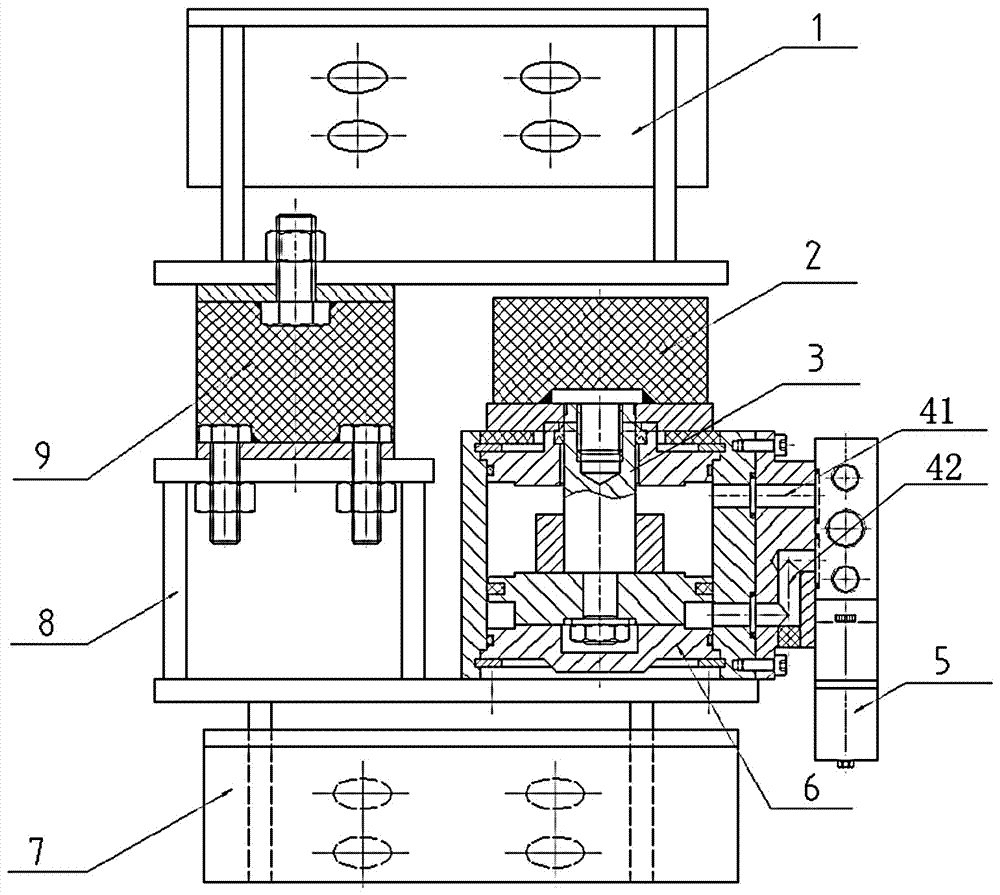

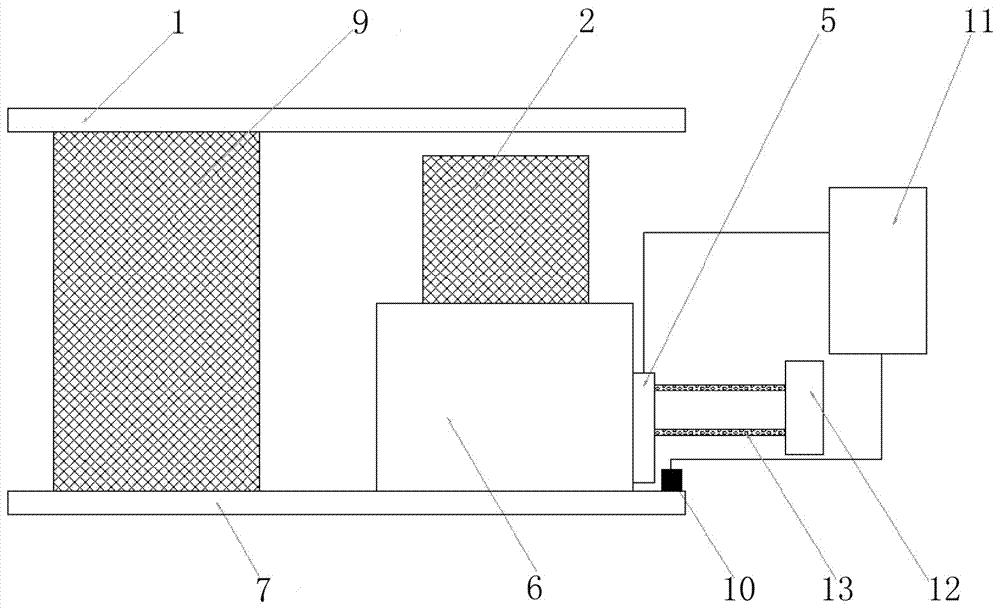

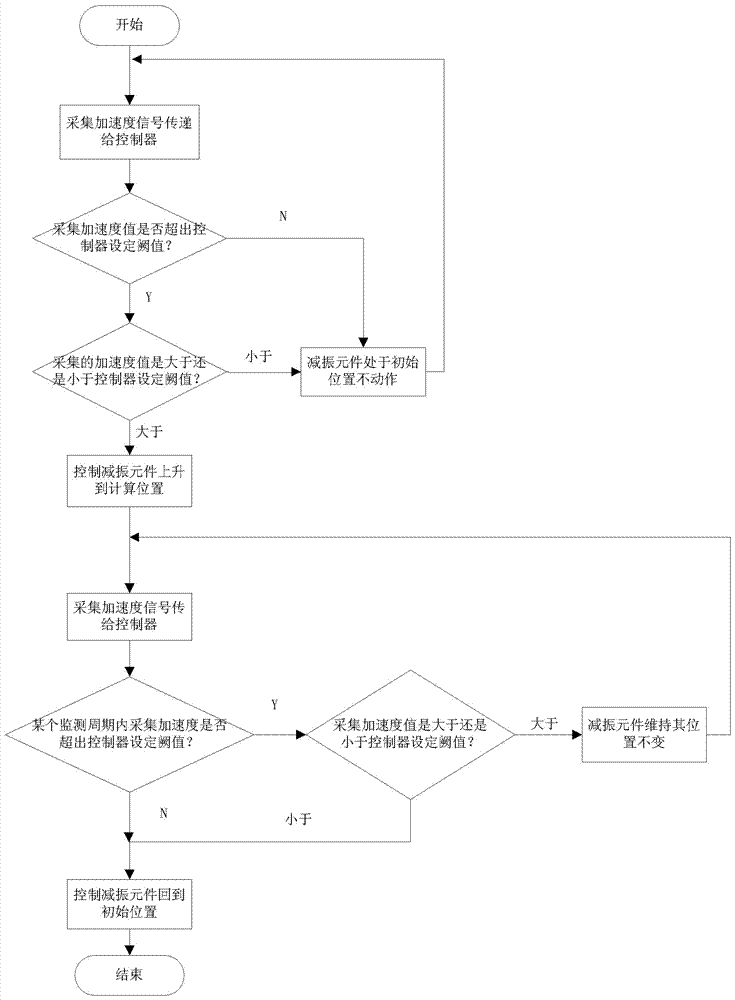

[0024] Embodiments of the suspension in the present invention: as Figure 1 to Figure 3 As shown, the suspension is a variable stiffness rubber suspension, which includes a vibrating frame 1 and a fixed frame 7 spaced up and down, and a vibration damping device is installed between the vibrating frame 1 and the fixed frame 7. The vibration damping device mainly It consists of a main damping element, an auxiliary damping element 2, a driving mechanism, a controller and a sensor 10, wherein the main damping element and the auxiliary damping element 2 are arranged in parallel, and the main damping element is composed of a connecting bracket and a supporting rubber pad 9, The top bolts of the supporting rubber pad 9 are connected to the vibrating frame 1, the bottom bolts are connected to the connecting bracket 8, and the bottom of the connecting bracket 8 is welded on the fixed frame 7, and the top bolts are connected to the supporting rubber pad 9; the auxiliary vibration damping...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com