A fracturing operation method for a soluble full-bore sliding sleeve

A full-bore, sliding-sleeve technology, used in earth-moving drilling, fluid production, wellbore/well components, etc., can solve problems such as inability to achieve infinite fracturing, affecting on-site construction progress, and difficulty in running tools in later stages. , to achieve the effect of infinite fracturing operation, maintain full diameter and integrity, and improve the success rate of opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

[0033] A fracturing operation method for a soluble full-bore sliding sleeve, which comprises the following steps:

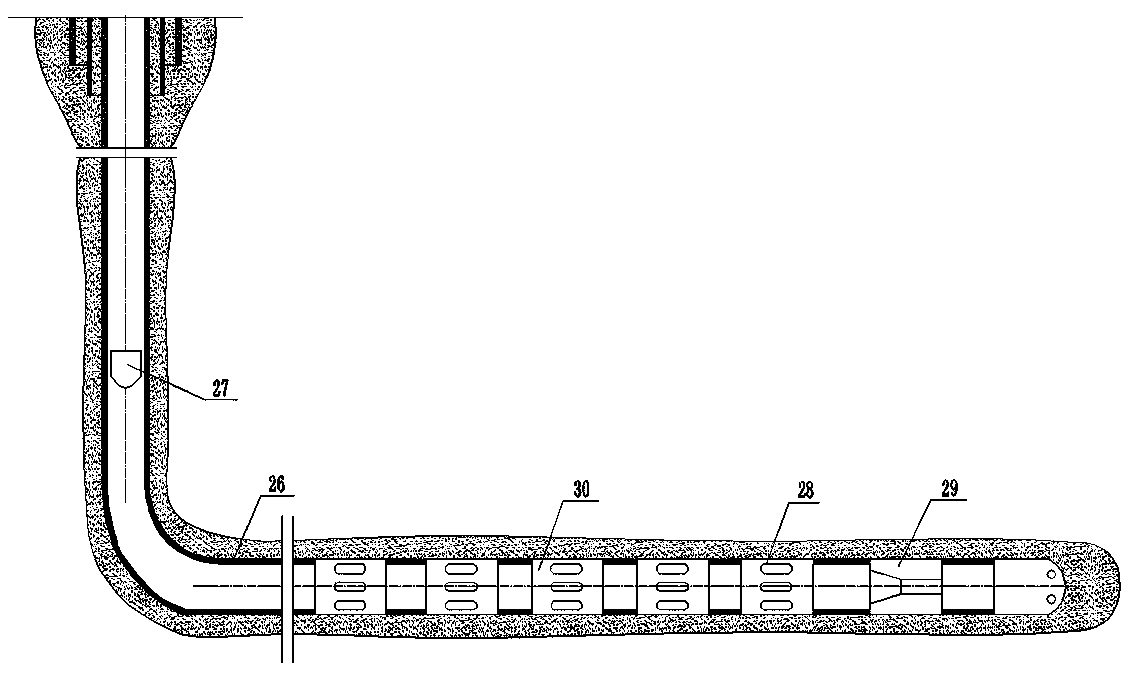

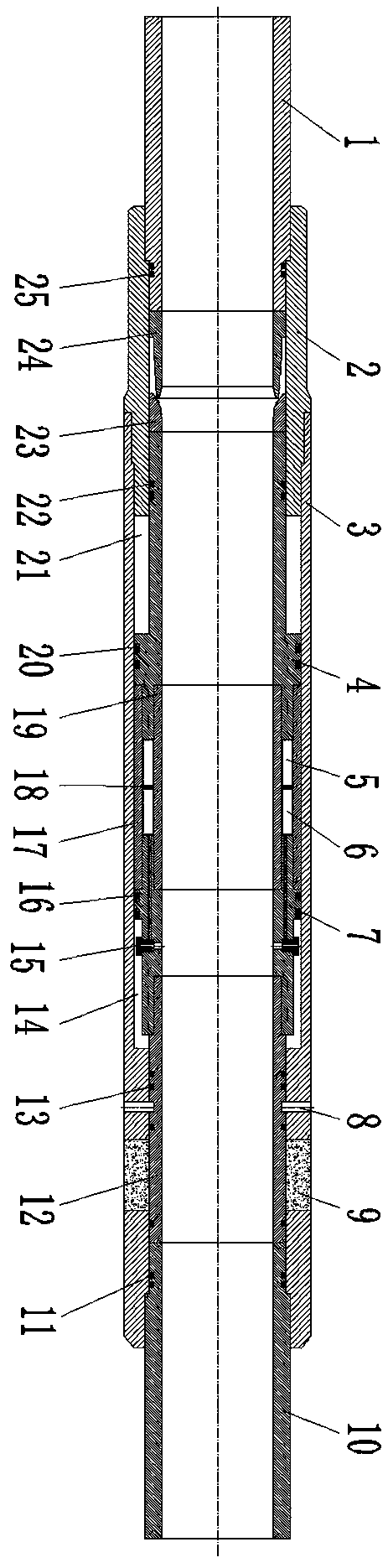

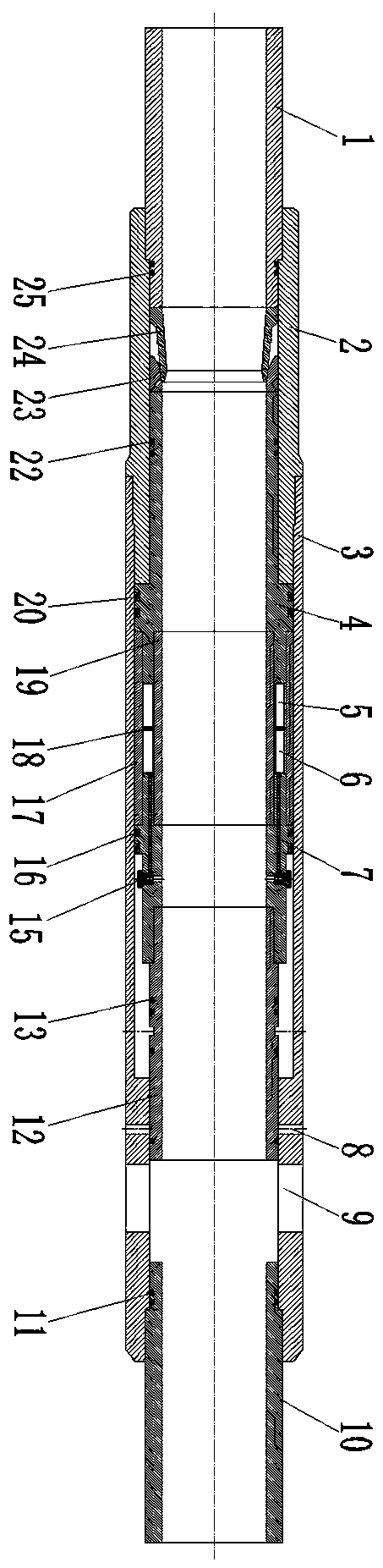

[0034] S1. Collect formation pressure, well temperature, maximum vertical depth, parameters of production casing 26 and performance data of the liquid in the wellbore, and select soluble full-bore sliding sleeve 30 and casing toe sliding sleeve 28 with corresponding temperature, pressure and size;

[0035] S2. Collect well logging interpretation, reservoir segmentation, wellbore structure and production casing 26 button type data, and complete the design of the well string structure, in which the running position of the soluble full-bore sliding sleeve 30 should correspond to different reservoir stimulations layer section, and determine the opening quantity of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com