Novel prefabricated type building thermal-insulation block system and assembly method thereof

A technology for building thermal insulation and thermal insulation blocks, which is applied in construction, building materials, building components, etc., can solve the problems of increasing cold bridges, easy disintegration of composite self-insulating blocks, and increased costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

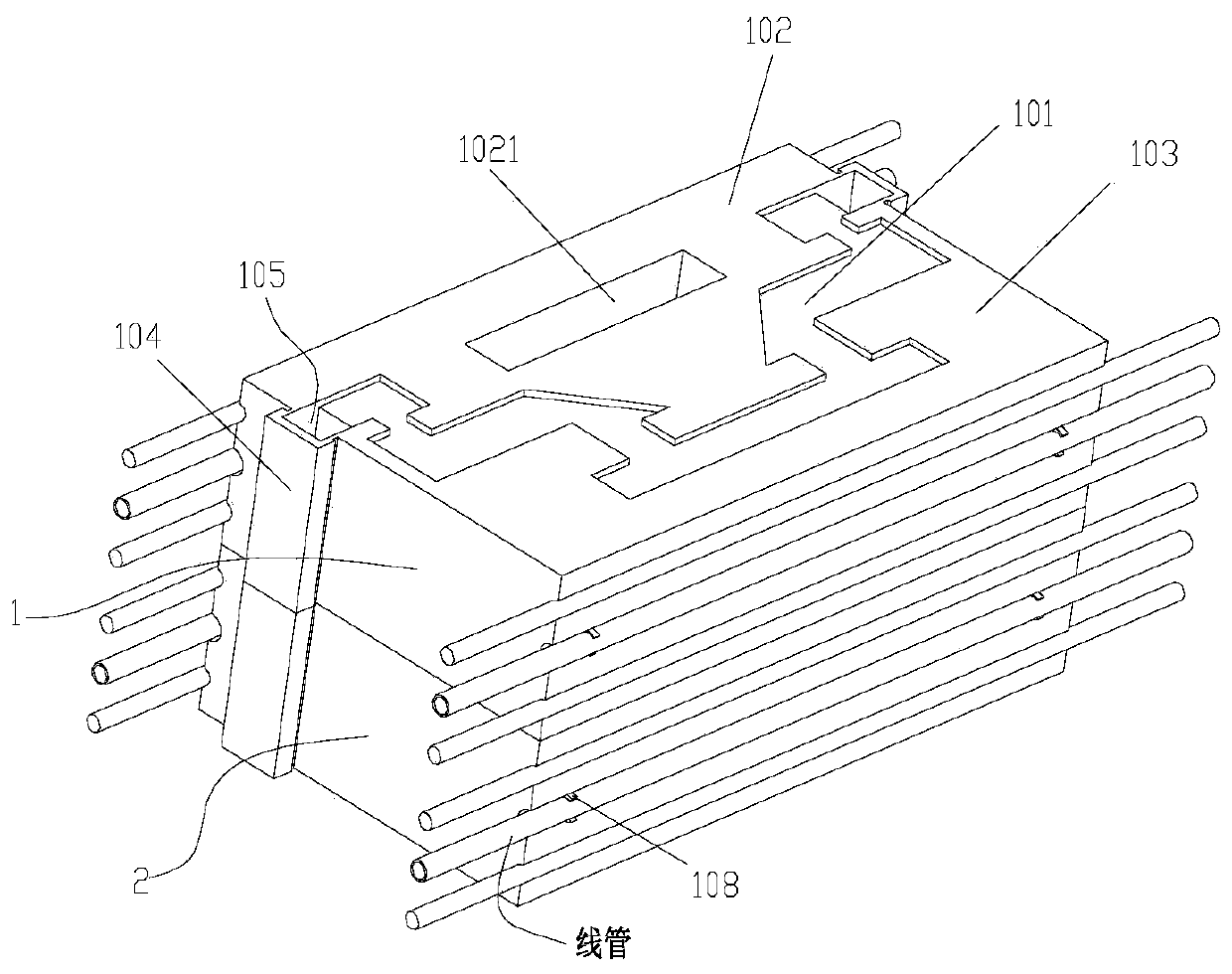

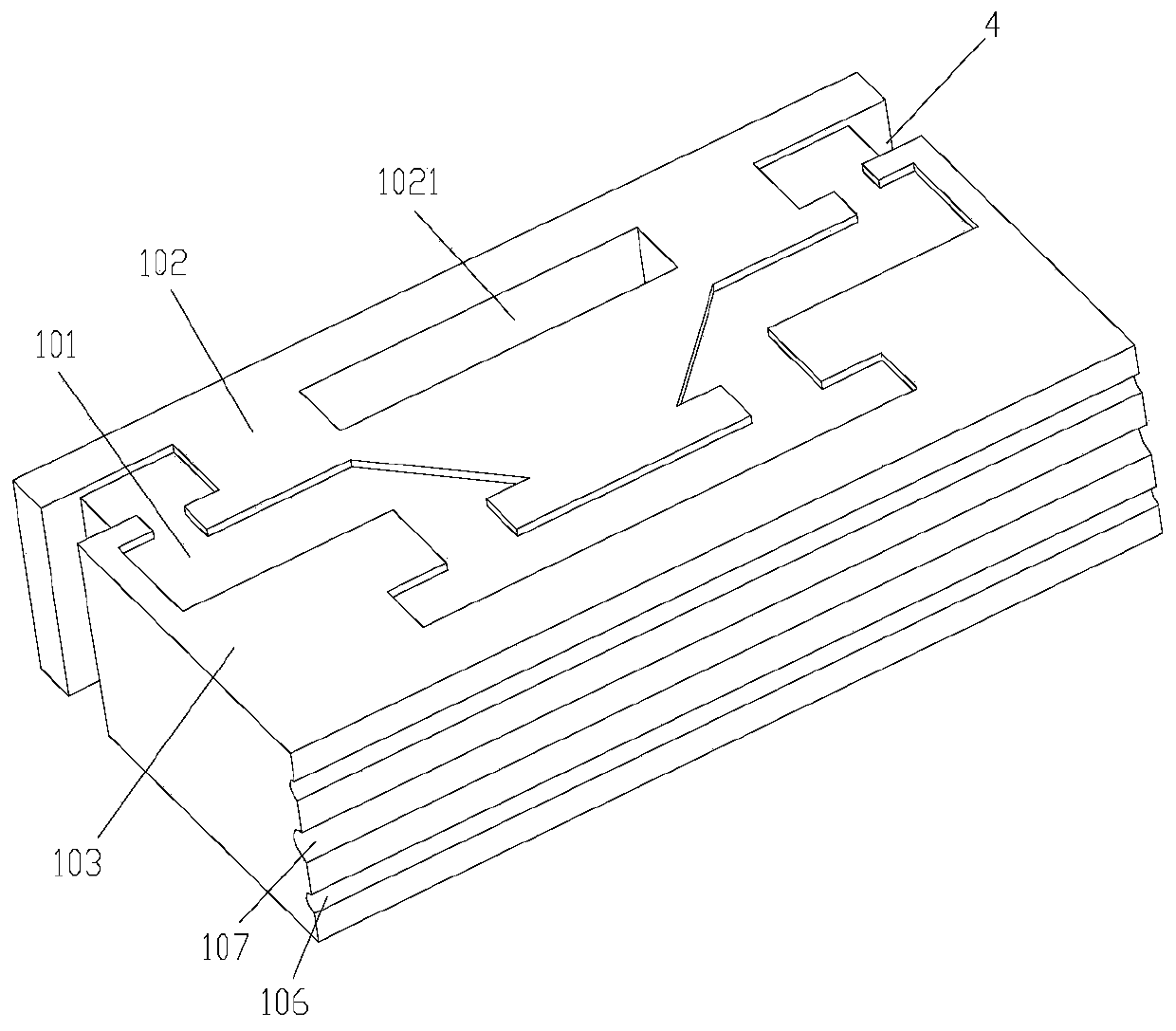

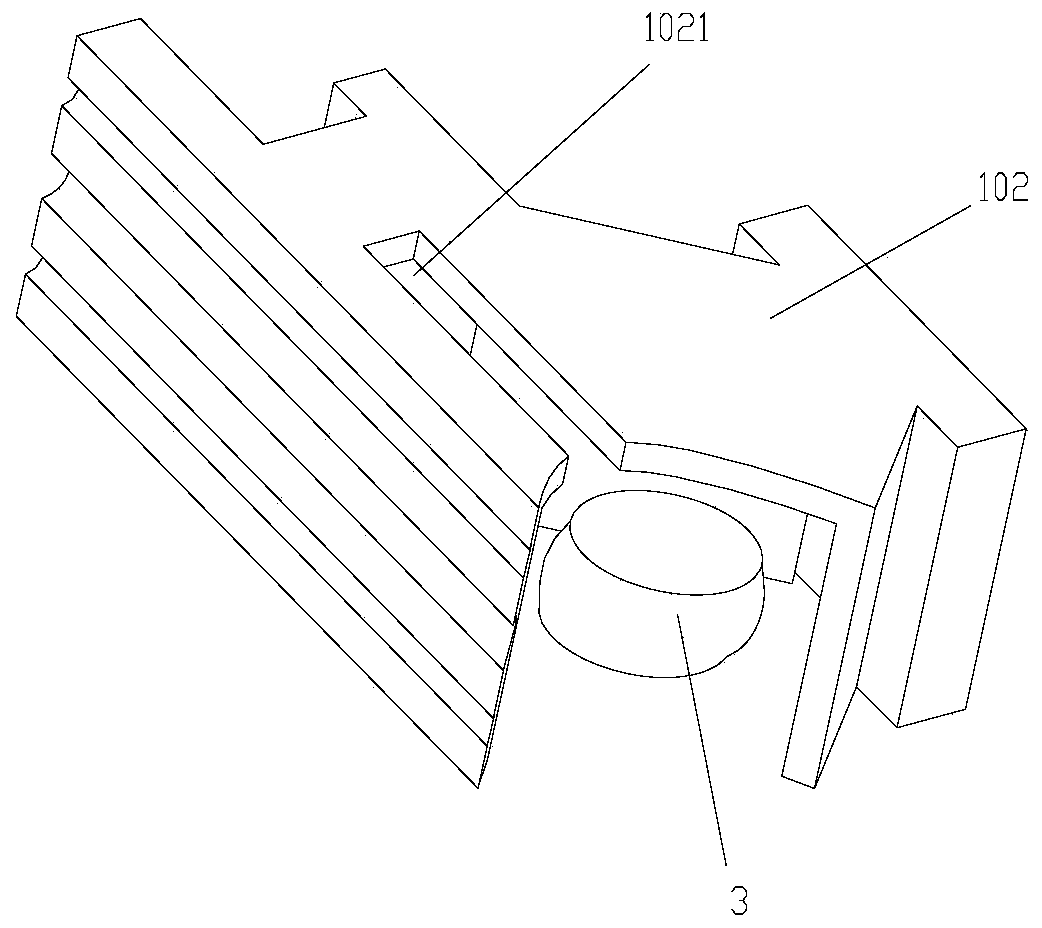

[0023] As shown in the figure: a new type of prefabricated building thermal insulation block system according to the present invention includes a composite thermal insulation block and a steel cage for enhancing the stability of the thermal insulation block after laying. block 1 and lower block 2, the upper block 1 and the lower block 2 form a symmetrical structure, the lower part of the upper block 1 is provided with a cavity for filling the vacuum bag 3, and the upper end of the upper block 1 is provided with a The steps in the front and rear direction have a step ESP insulation layer 101, and the end faces of the outwardly extending ends of the step ESP insulation layer 101 are indented inwardly with a distance of 5-10cm left on the outer side of the upper block 1 to form a reserved groove 4 and will The upper block is divided into a front block 103 and a rear block 102, the cavities are all located inside the rear block 102, and the reserved groove 4 is filled with slurry o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com