Glitter powder with color changed with angle and processing equipment of glitter powder

A processing equipment and a technology for glitter powder, which are applied in the directions of devices and coatings for coating liquid on the surface, can solve the problems of poor discoloration and flashing effects, low efficiency of artificial coating, and adverse health, and achieve low manufacturing costs. , Improve the effect of color change and sparkle, and improve the efficiency and effect of painting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

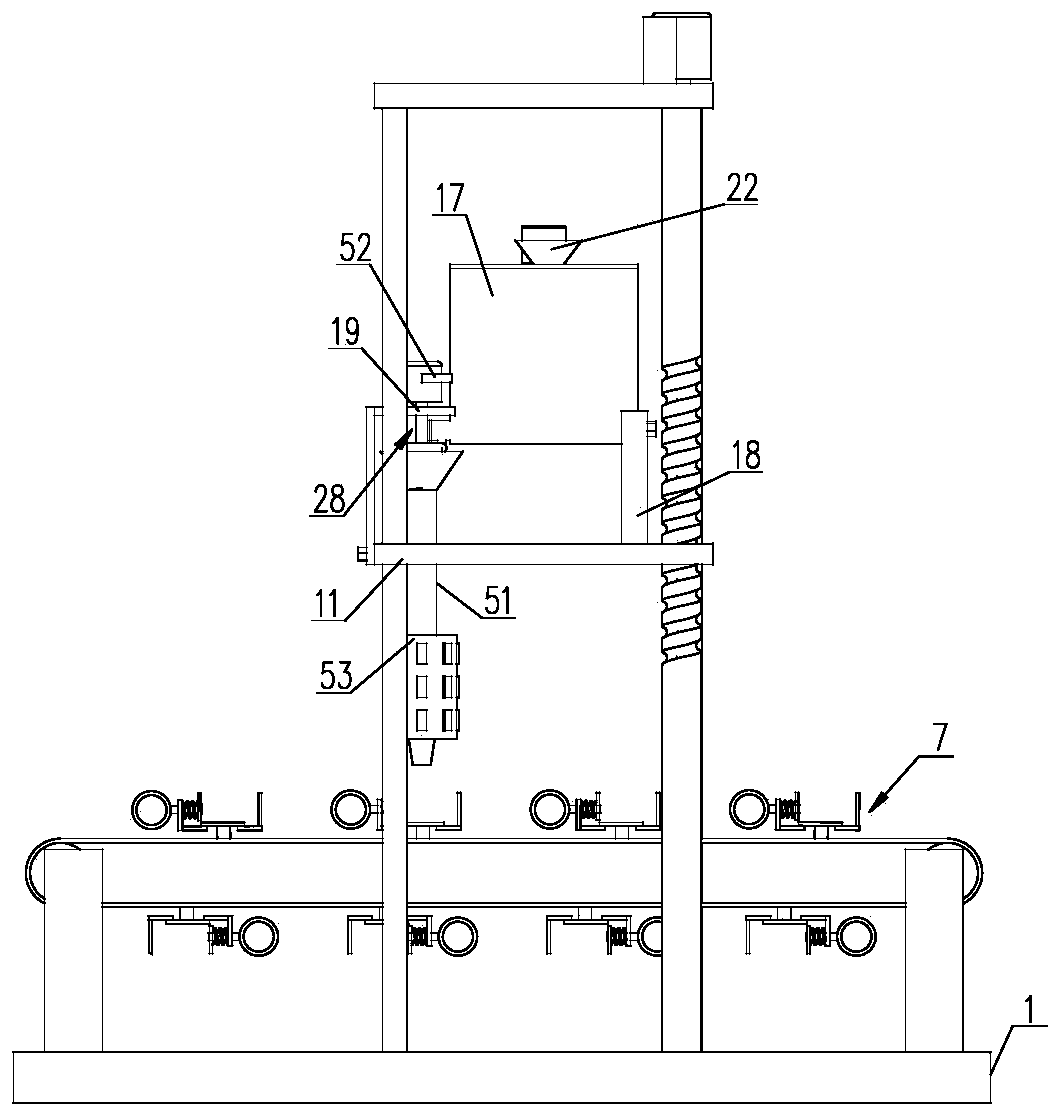

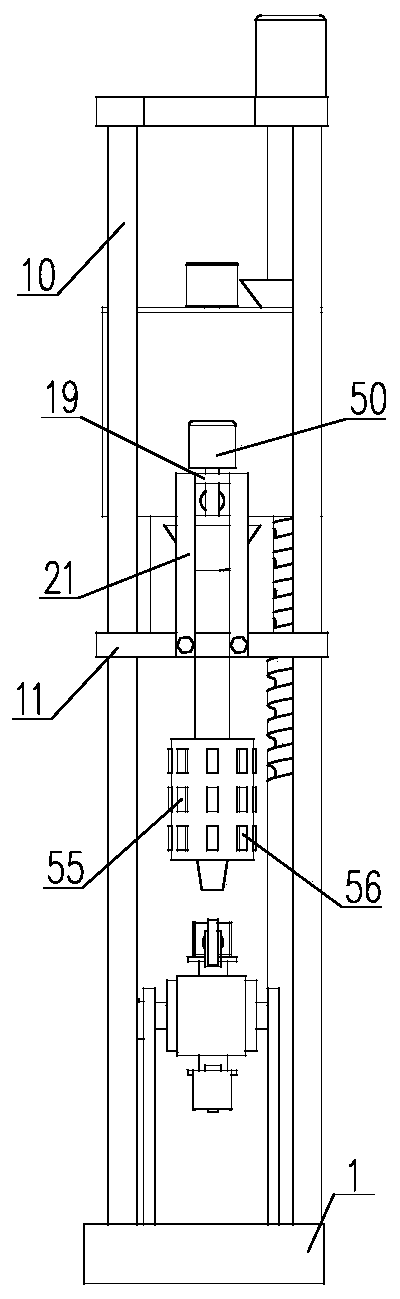

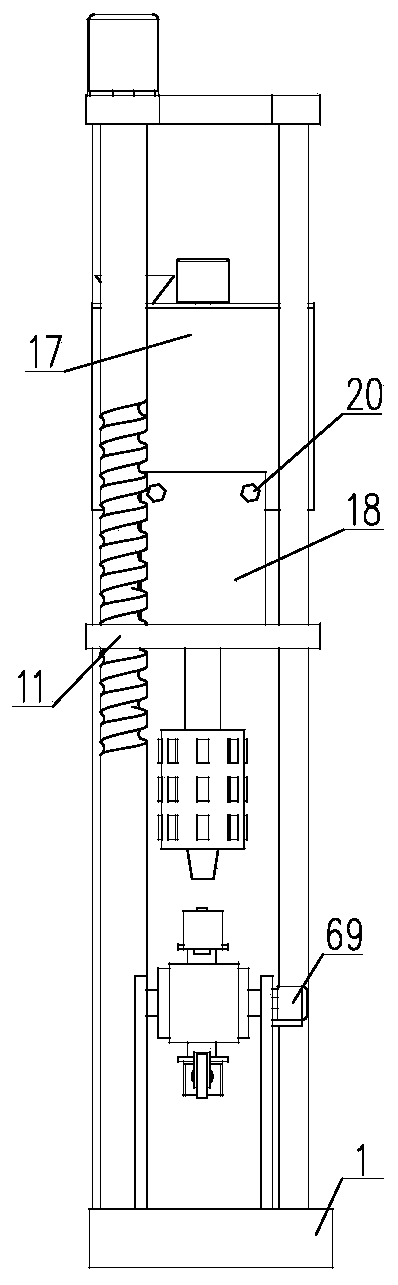

[0032] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0033] A kind of glitter powder that changes color with angle, including the following components by weight, 2-3 parts of epoxy resin A glue, 2-3 parts of epoxy resin B glue, 12-16 parts of color changing powder, 4-3 parts of organic oligomer 6 parts, 11-17 parts of tetraethoxysilane, 2-5 parts of ethylene glycol ether, 16-24 parts of polycarbosilane, 8-12 parts of nano oxide filler, 1-3 parts of silicon dioxide, 13 parts of flash powder -15 parts, 9-10 parts of leveling agent, 15-18 parts of tetrahydrofuran, 10-12 parts of xylene, 0.5-0.7 parts of sodium hexametaphosphate, 0.8-1 part of phthalocyanine blue and 3-6 parts of n-butanol. In this embodiment, 2.5 parts of epoxy resin A glue, 2.5 parts of epoxy resin B glue, 15 parts of color changing powder, 5 parts of organic oligomer, 14 parts of tetraethoxysilane, 3 parts of ethylene glycol ether, poly 18 part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com