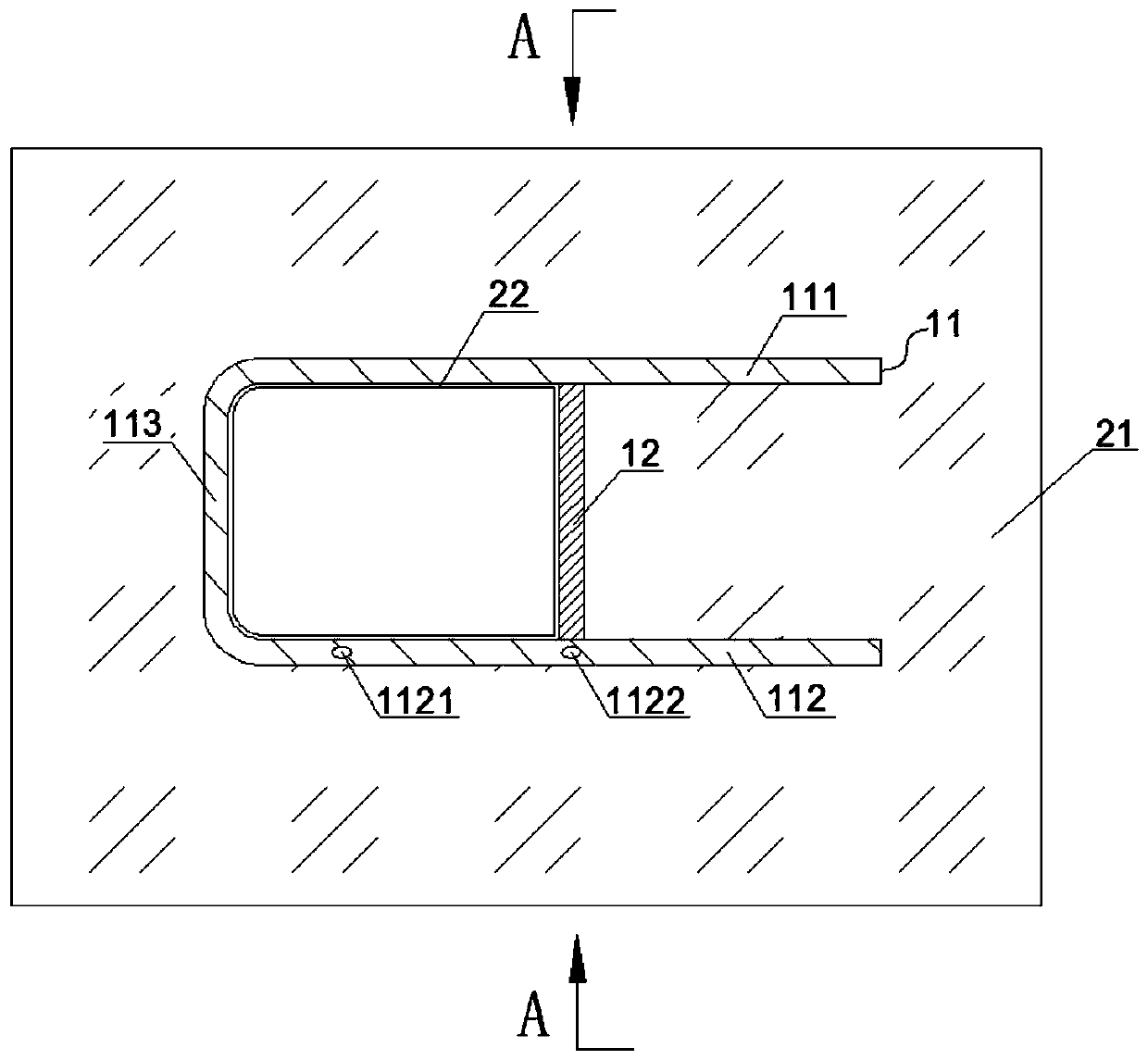

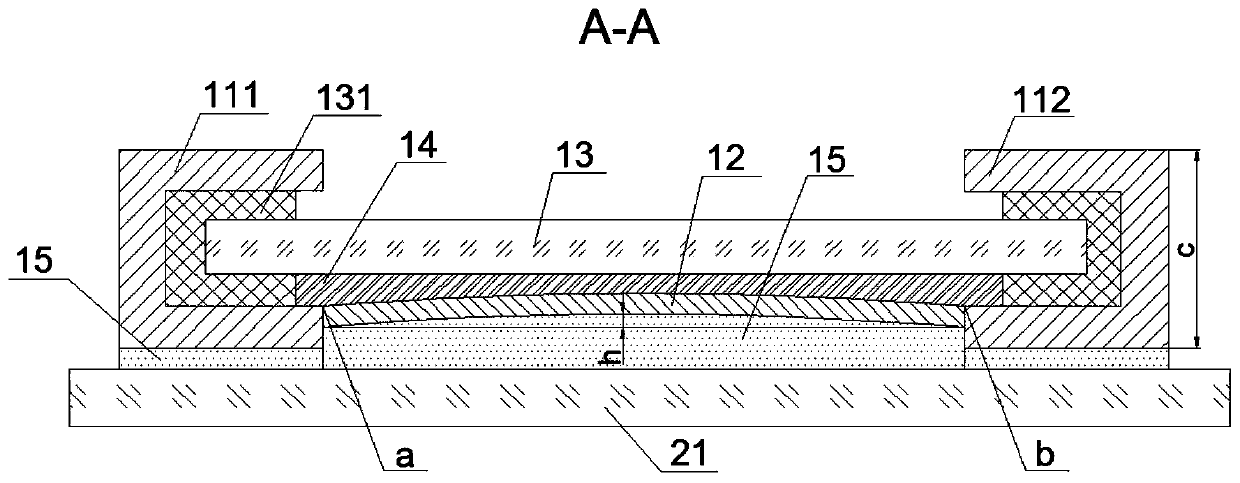

Window body device and military helicopter with same

A technology for helicopters and windows, applied in the field of windows, can solve the problems of sliding rail cracking, sliding rail falling off, sliding rail opening glue, etc., to achieve the effect of not easy to crack, not easy to fall off or shift, and not to scratch the glass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] As a preferred embodiment, the preparation method of the primer treatment agent comprises the following steps: the preparation method of the primer treatment agent comprises the following steps: at normal temperature, the N-(β-aminoethyl-γ -aminopropyl)trimethoxysilane, epoxy 3-(2,3-glycidoxy)propyltrimethoxysilane, acryloxy γ-(methacryloxy)propyltrimethoxy The silane, isopropanol and nano carbon black are hydrolyzed, mixed, and condensed at 90-120 DEG C to obtain the primer treatment agent.

[0057] Before mixing, the above components are hydrolyzed separately at normal temperature, and then all the components are mixed uniformly at 90-120° C. for condensation reaction to connect the multifunctional groups.

[0058] The raw material of the primer treatment agent of the present invention contains a variety of coupling agents. Before mixing, the above components are hydrolyzed separately at room temperature to form hydroxyl groups that can undergo condensation reactions,...

Embodiment 1

[0103] A primer treatment agent for polyurethane structural adhesives, which is made from the following raw materials in mass percent: N-(β-aminoethyl-γ-aminopropyl) trimethoxysilane 10%, epoxy 3- (2,3-Glycidoxy)propyltrimethoxysilane 30%, Acryloyloxy γ-(Methacryloyloxy)propyltrimethoxysilane 20%, Isopropanol 39.5% and Nano Carbon Black 0.5%.

[0104] The preparation method of the primer treatment agent comprises: firstly hydrolyzing the above components separately at normal temperature, and then mixing all the components uniformly at 100° C. to carry out condensation reaction.

Embodiment 2

[0106] A primer treatment agent for polyurethane structural adhesives, which is made from the following raw materials in mass percent: N-(β-aminoethyl-γ-aminopropyl) trimethoxysilane 15%, epoxy 3- (2,3-glycidyloxy) propyl trimethoxysilane 20%, acryloxy γ-(methacryloxy) propyl trimethoxysilane 10%, isopropanol 54.9.% and nano carbon Black 0.1%.

[0107] The preparation method of the primer treatment agent comprises: firstly hydrolyzing each of the above components at room temperature, and then mixing all the components uniformly at 90° C. to carry out condensation reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com