Hydrostatic pressure releasing device for life raft

A hydrostatic pressure and releaser technology, applied in the field of underwater automatic release devices, can solve the problems of easy corrosion and dull rust, insufficient reliability, product failure, etc., and achieve the effects of safe release, reduced production cost, and strong reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be further described below in conjunction with the drawings and examples. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

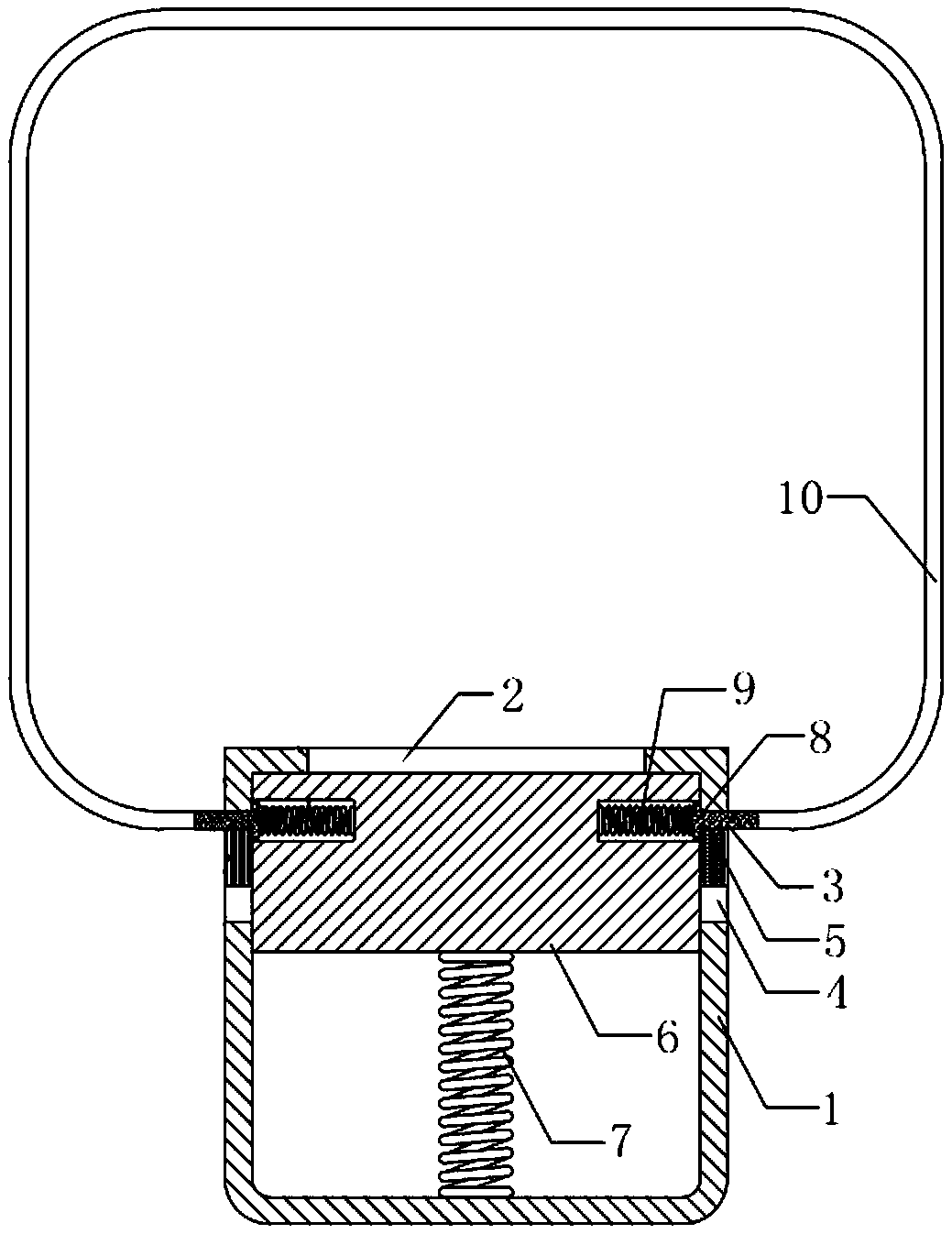

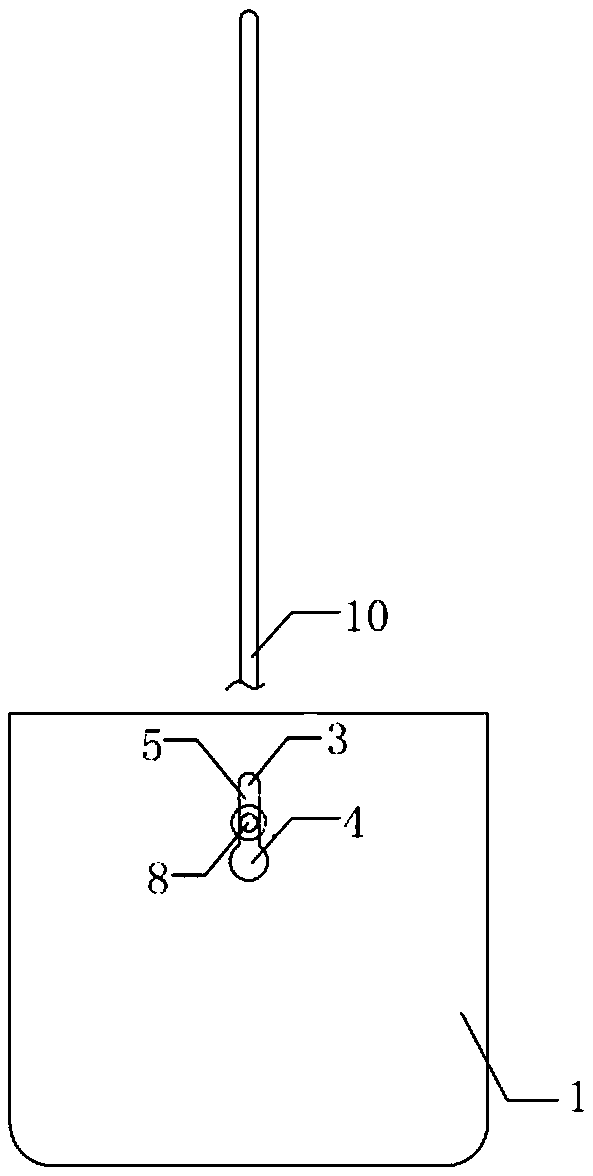

[0015] Such as figure 1 , figure 2 As shown, a hydrostatic pressure release device for a life raft includes a shell 1, a water inlet 2 is provided on one side of the shell 1, and an opening 3 and a breakout 4 are provided on the other two sides of the shell 1 near the water inlet 2, and the opening 3 is connected to the water inlet 2. The outlets 4 communicate with each other through the slideway 5; a diaphragm 6 is provided in the casing 1 close to the water inlet 2, and the end of the diaphragm 6 away from the water inlet 2 of the casing 1 is fixedly connected to the inner side of the casing 1 through a compression spring 7, and the membrane A release ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com