Lean intelligent assembly line for start-stop starter

An assembly line and starter technology, which is applied to assembly machines, metal processing, metal processing equipment, etc., can solve the problems of inaccurate identification of defective products and low efficiency, and achieve the effects of reducing quality risks, eliminating missing installations, and reducing the number of personnel on the entire line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] The following examples are presented to illustrate certain embodiments of the invention and should not be construed as limiting the scope of the invention. The content disclosed in the present invention can be improved simultaneously from materials, methods and reaction conditions, and all these improvements should fall within the spirit and scope of the present invention.

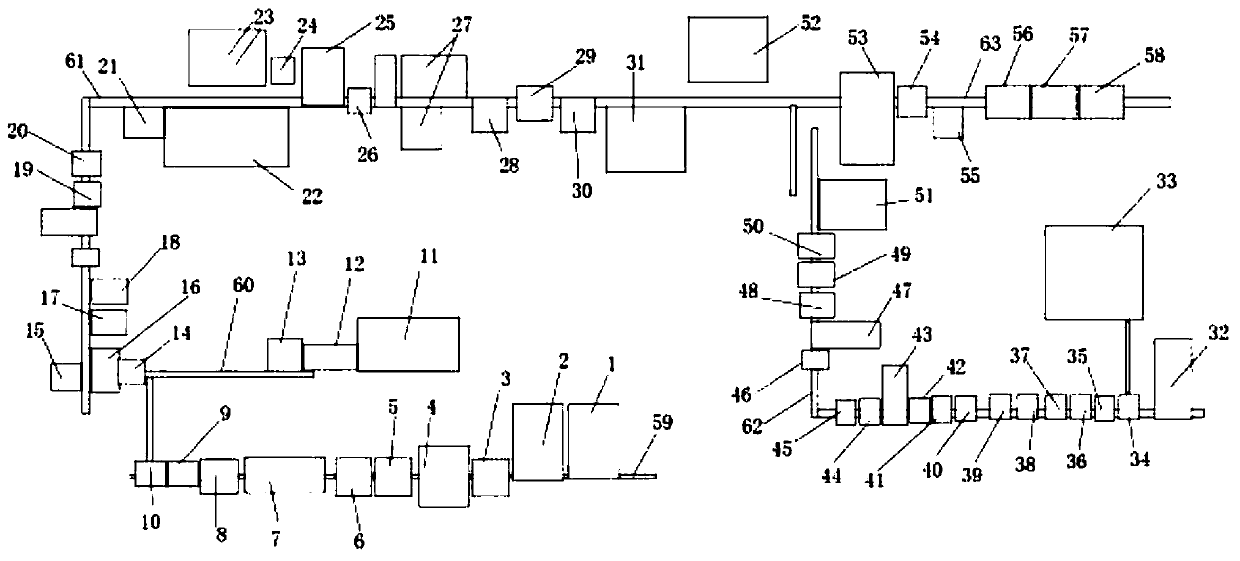

[0050] like figure 1 As shown, the start-stop starter lean intelligent assembly line includes a one-way assembly assembly line 59, a drive shaft assembly assembly line 60, a starter assembly assembly line 61, an electromagnetic switch assembly assembly line 62, and a factory performance inspection line 63. It is characterized in that ,

[0051] The assembly line 59 of the one-way device assembly is equipped with guide cylinder oiling line 1, gear shaft loading 2, gear automatic spinning 3, cover gasket assembly 4, cover extrusion 5, cover shaping 6, pagoda installation Spring 7, install slip ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com