Automatic power transmission equipment

A technology of power transmission equipment and brushes, which is applied in the field of power transmission, and can solve problems such as failure of generators, poor contact of tip scales, and insufficient pressure of brushes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

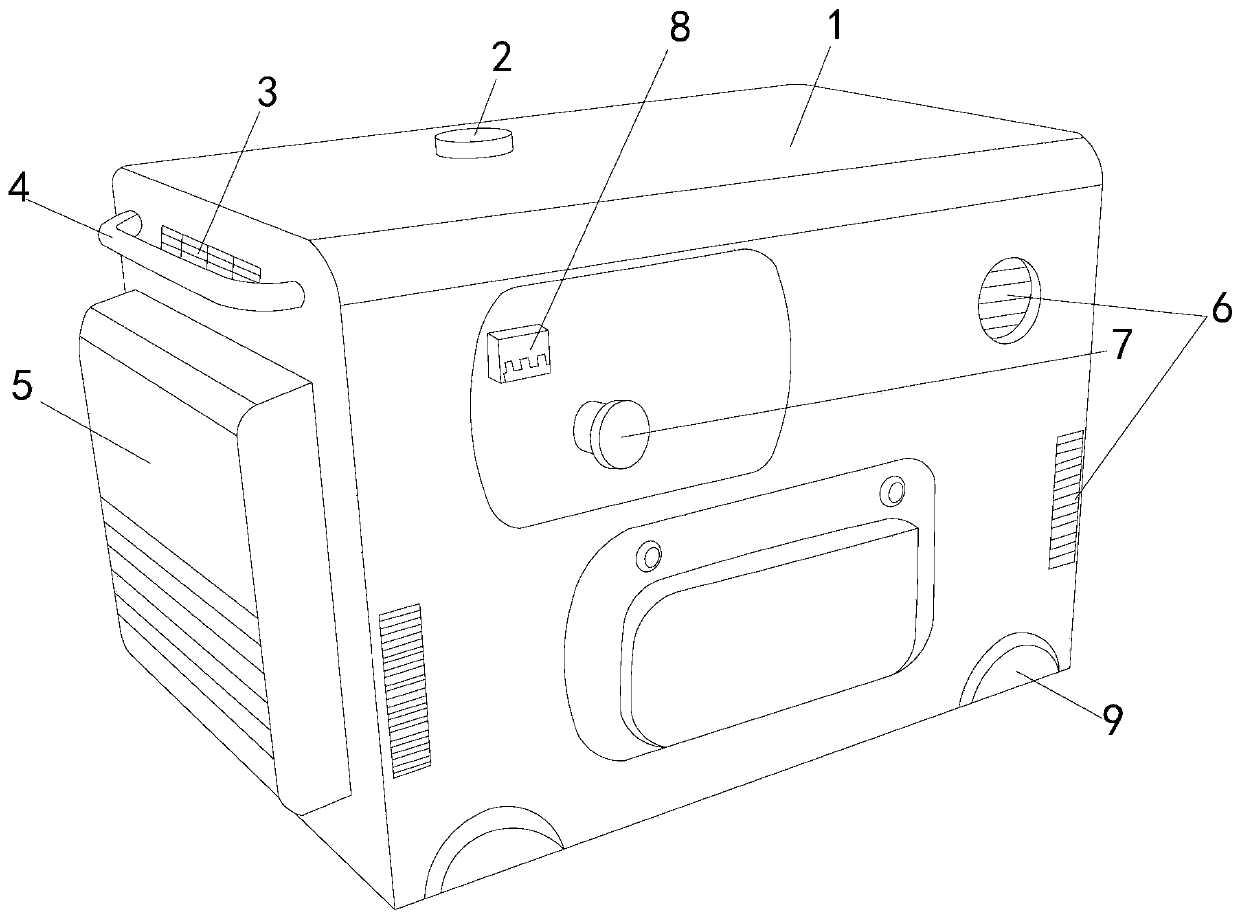

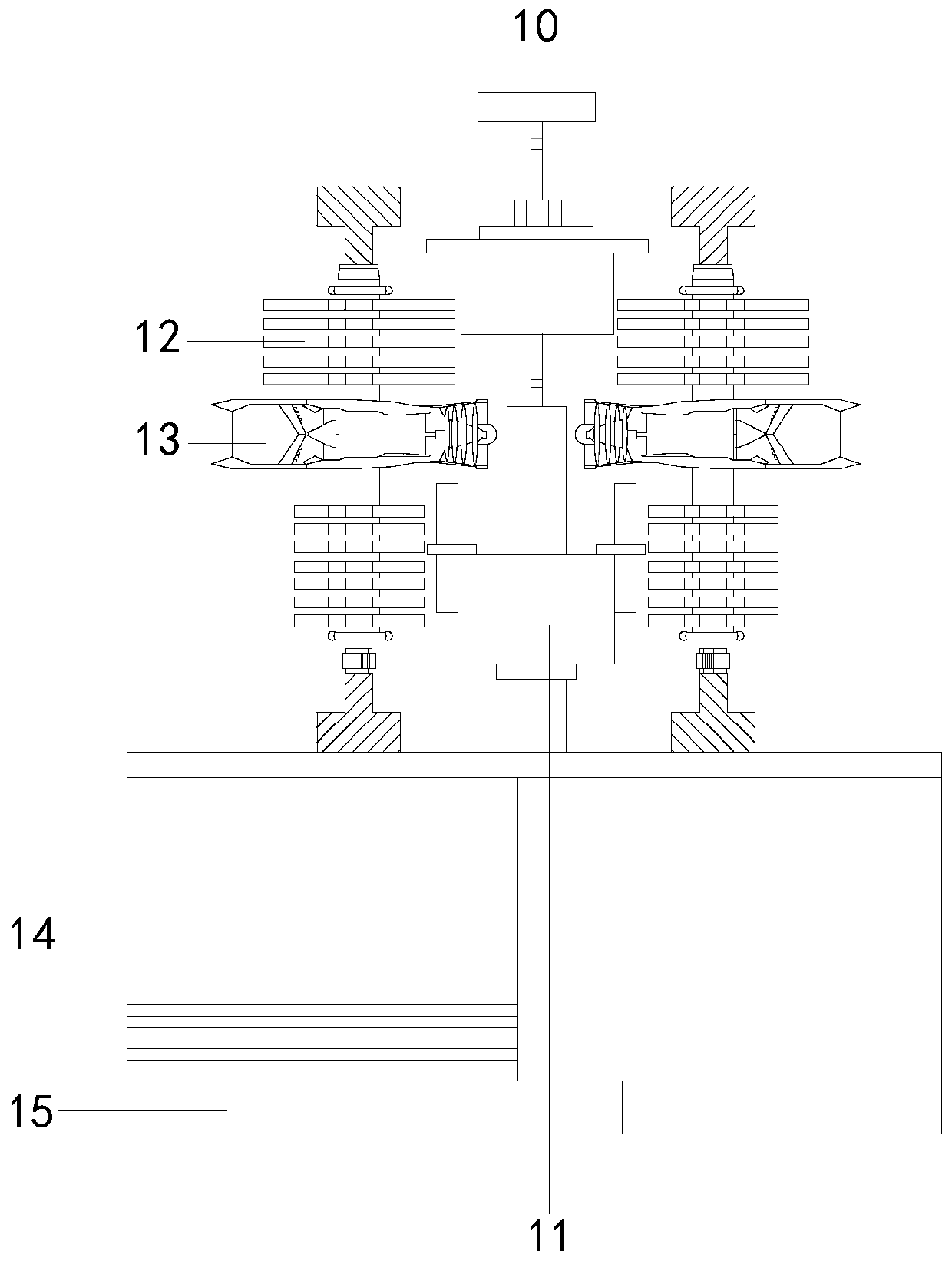

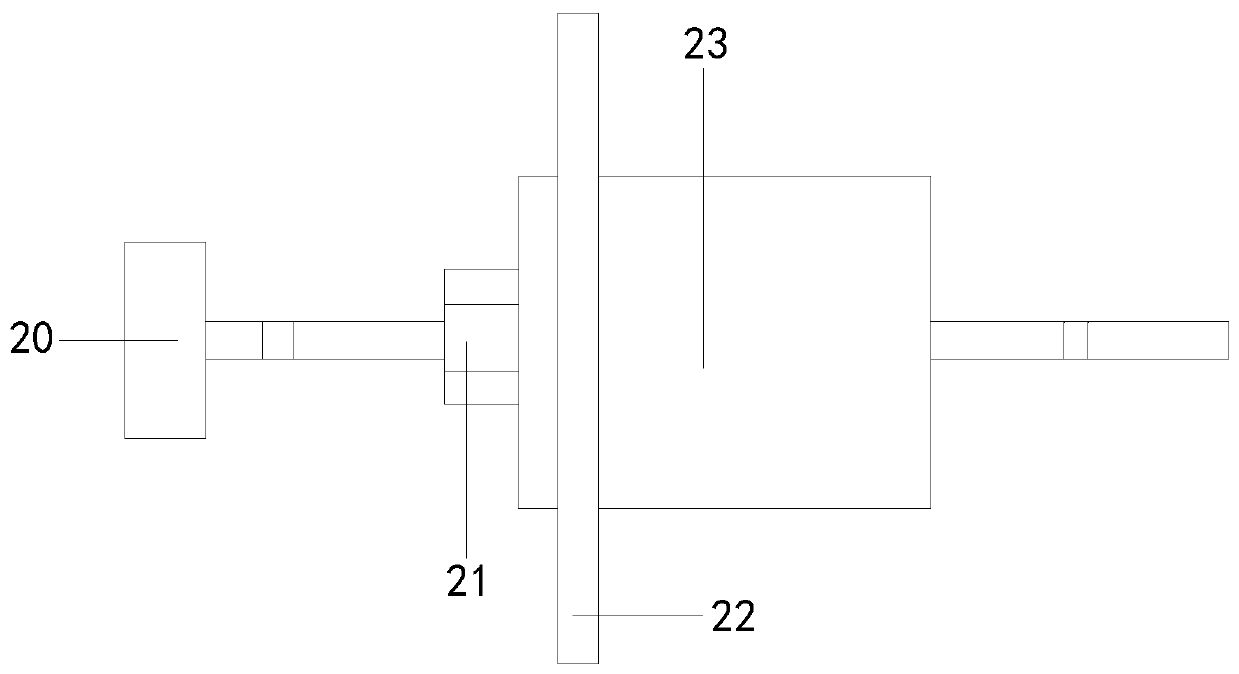

[0022] see figure 1 , the present invention provides an automatic power transmission equipment, its structure includes: machine body 1, brushing mechanism 2, air intake net 3, handle bar 4, rectifier 5, heat dissipation net 6, start switch 7, brake master brake 8, anti-skid block 9. The machine body 1 is equipped with a brushing mechanism 2, the air intake net 3 and the grip bar 4 are located on one side of the body 1, the body 1 is connected to the rectifier 5 and is provided with a heat dissipation net 6, the start switch 7 and the brake master brake 8 is located on the front of the machine body 1 and connected with it. The bottom of the machine body 1 is provided with an anti-skid block 9. The machine body 1 is the main load-bearing structure of the equipment, which is used to connect other components and provide them with protective performance to prevent them from being affected by external electricity and lightning strikes. It is made of high-strength insulating materia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com