A multi-stage screening device for soybean seeds

A soybean seed and screening device technology, which is applied in the agricultural field, can solve the problems of inconvenient promotion and implementation, inability to multi-stage screening of soybean seeds, poor classification ability, etc., and achieve the effect of simple structure, low production cost, and improved cleanliness level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

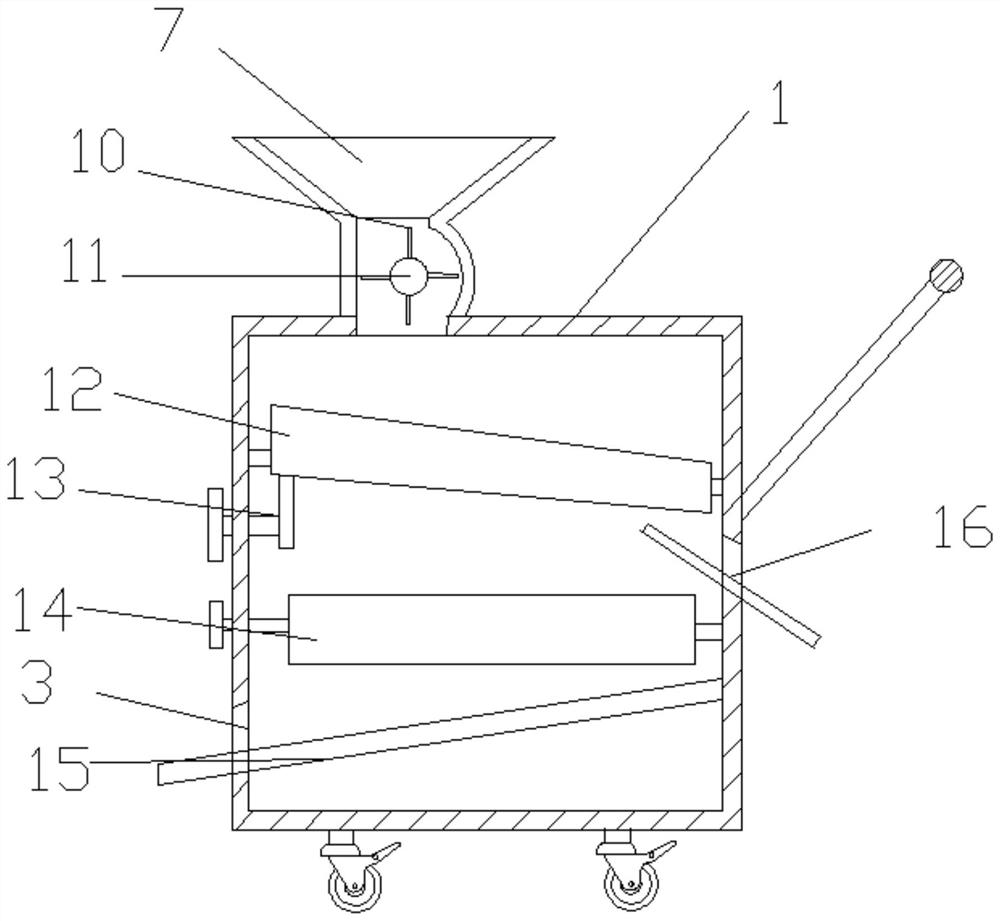

[0024] see Figure 1-4 , a multi-stage screening device for soybean seeds, including a box body 1 and a feeding hopper 7, the bottom four corners of the box body 1 are provided with universal wheels, the universal wheels are provided with braking devices, and the braking devices have a control on the universal wheels. Action, the setting of the universal wheel facilitates the movement and fixation of the device. The top of the box body 1 is connected with a feeding hopper 7. The soybean seeds to be graded are placed inside the feeding hopper 7. A feeding device 8 is installed on the feeding hopper 7. Through the feeding device 8, the soybeans inside the feeding hopper 7 are at a constant speed. Controlled entry into the box 1 for screening.

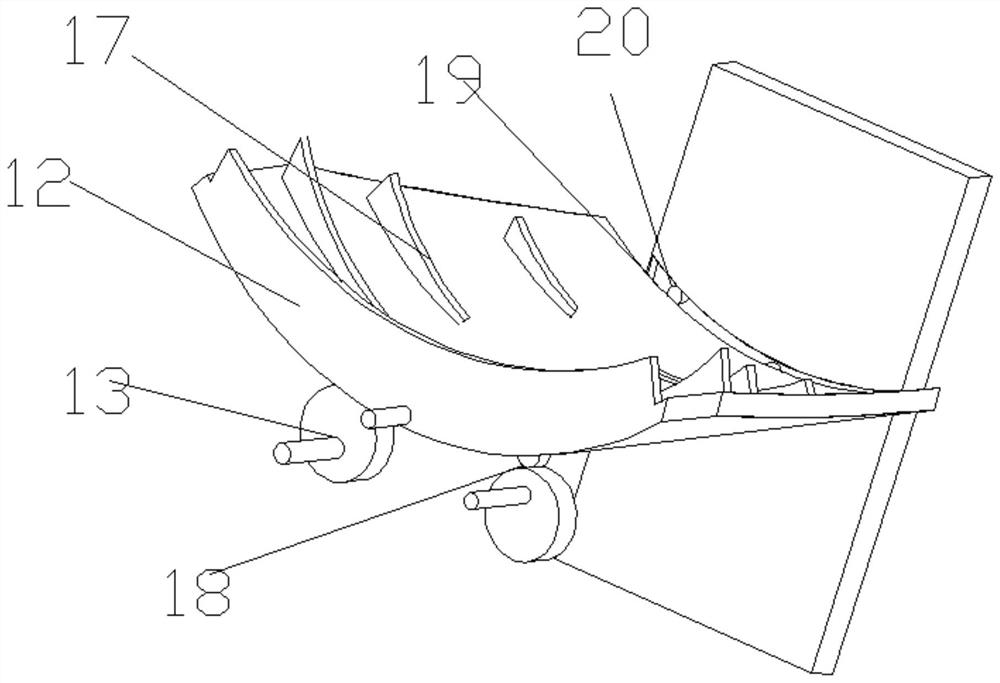

[0025] A rocking plate 12 is inclined inside the box body 1 , and the rocking plate 12 is an arc-shaped structure with one end close to the feeding hopper 7 wide and one end far away from the feeding hopper 7 . Two eccentric wheels 13 a...

Embodiment 2

[0029] On the basis of Embodiment 1, the feeding device 8 includes a second motor 9 and a rotating shaft 11 . The rotating shaft 11 is rotatably arranged on the inner bottom of the feeding hopper 7 , and a plurality of rotating blades 10 are fixedly arranged on the rotating shaft 11 , and the rotating blades 10 and the interior of the feeding hopper 7 are rotatably sealed. One end of the rotating shaft 11 extends out of the feeding hopper 7 and is coaxially connected with the output shaft of the second motor 9 fixed on the outer wall of the feeding hopper 7 . Driven by the second motor 9 , the rotating shaft 11 rotates, and the rotating blade 10 rotates the soybeans inside the feeding hopper 7 into the inside of the box 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com