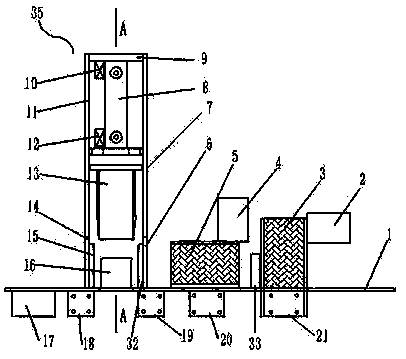

Full-automatic sugarcane seed bud cutting machine

A cutting machine, fully automatic technology, applied in the direction of rhizome seed cutting machine, seed and rhizome processing, metal processing, etc., can solve the problems of long sugarcane segment, low efficiency, waste, etc., to achieve cutting bud specifications, high efficiency, Labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The fully automatic sugarcane seed bud cutting machine comprises a base plate 1 on which a cutting mechanism 35, a reversing mechanism 36 and a feeding mechanism 37 are installed, the cutting mechanism 35 is provided with a cutting cylinder 8, and the tail end of the cutting cylinder 8 is installed on the top fixing plate 9 , and fixed by the left fixed plate 11 and the right fixed plate 7, the cutting cylinder 8 is provided with a magnetic switch A10 and a magnetic switch B12, the front end of the push rod is equipped with a cutting knife 13, the cutting direction is directly below, the right fixed plate 7 and the left fixed Plate 11 is respectively provided with sugarcane inlet 6 and sugarcane outlet 14, and front camera 16 and rear camera 26 are installed between left and right boards, is used for detecting the position of sugarcane bud or joint; Reverse mechanism 36 is provided with photoelectric switch 33 and motor A2, Motor A2 is connected to conveyor belt A3, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com