Siphon reverse slope drainage system and drainage method

A drainage system and siphon technology, applied in the directions of drainage, siphon pipe, earthwork drilling, etc., can solve the problems of large labor input and large power consumption, and achieve the effect of strong applicability, good reliability and small space occupation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

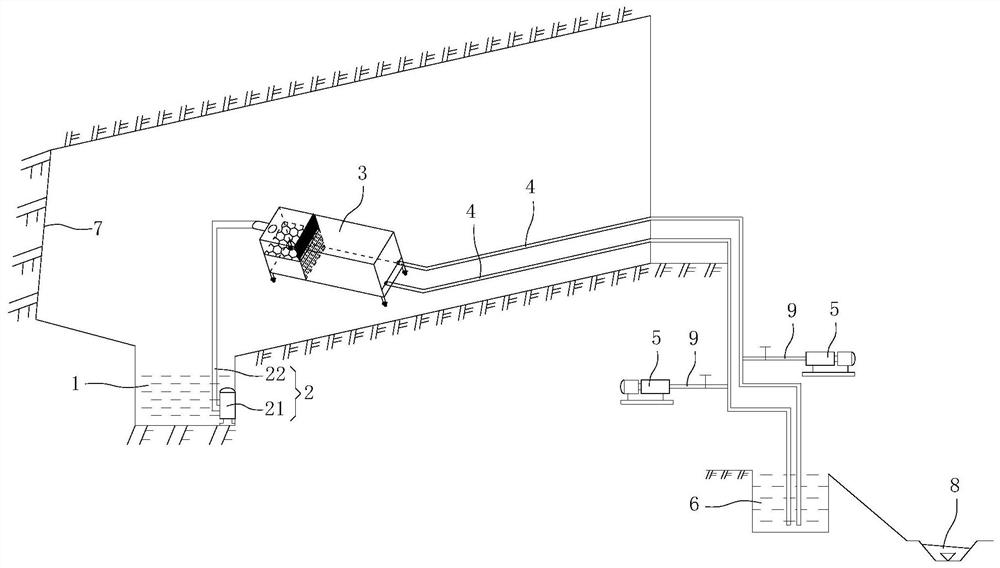

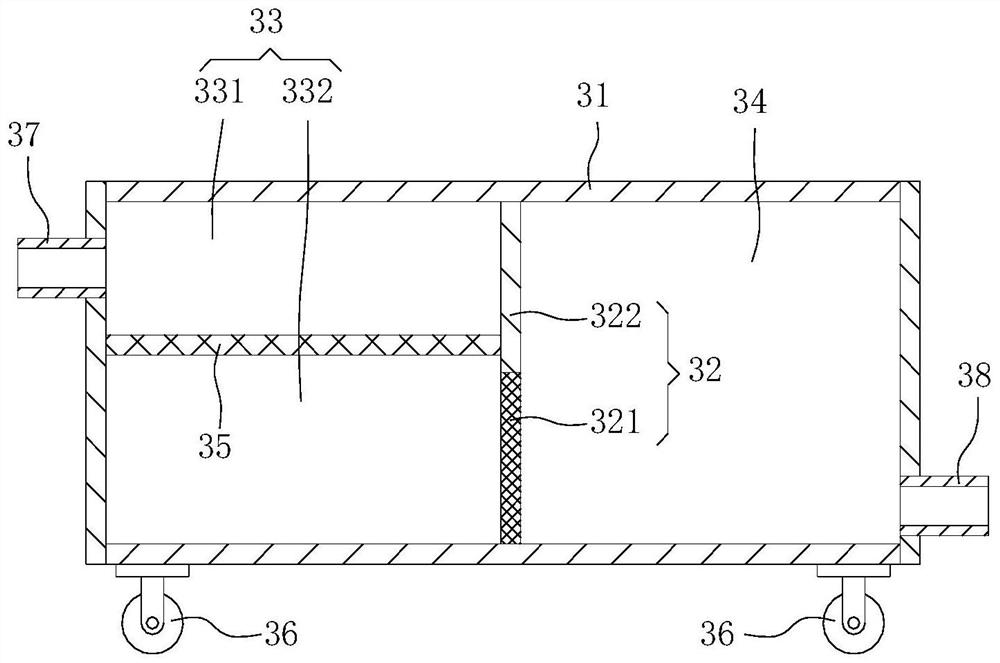

[0021] The siphon type reverse slope drainage system of the embodiment of the present invention comprises a sump 1, a water pumping device 2, a water collecting device 3, a siphon drainage pipe 4 and a vacuum pump 5; the sump 1 is arranged in a tunnel; the water collecting The device 3 is placed in the tunnel, and the inlet of the water collecting device 3 is communicated with the sump 1 through the pumping device 2; It is arranged outside the tunnel, and the elevation of the outlet of the siphon drainage pipe 4 is lower than that of the outlet of the water collecting device 3 ;

[0022] The working face 7 refers to the working face on which the excavation tunnel is continuously pushed forward. Such as figure 1 As shown, the sump 1 is a temporarily excavated sump, which is set near the face 7 of the rich water tunnel, and is used to collect the ground...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com