Extra-large steel structure supporting skeleton

A technology for supporting skeletons and steel structures, which is applied in basic structure engineering, building construction, roofing, etc., can solve the problems of slowing down steel structure skeletons, large skeletons occupying an area, and wasting a lot of time to achieve enhanced grip and contact The effect of increasing the area and reducing the time consumed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] For the convenience of those skilled in the art to understand, the following in conjunction with the attached Figure 1-6 The technical solution of the present invention is further described in detail.

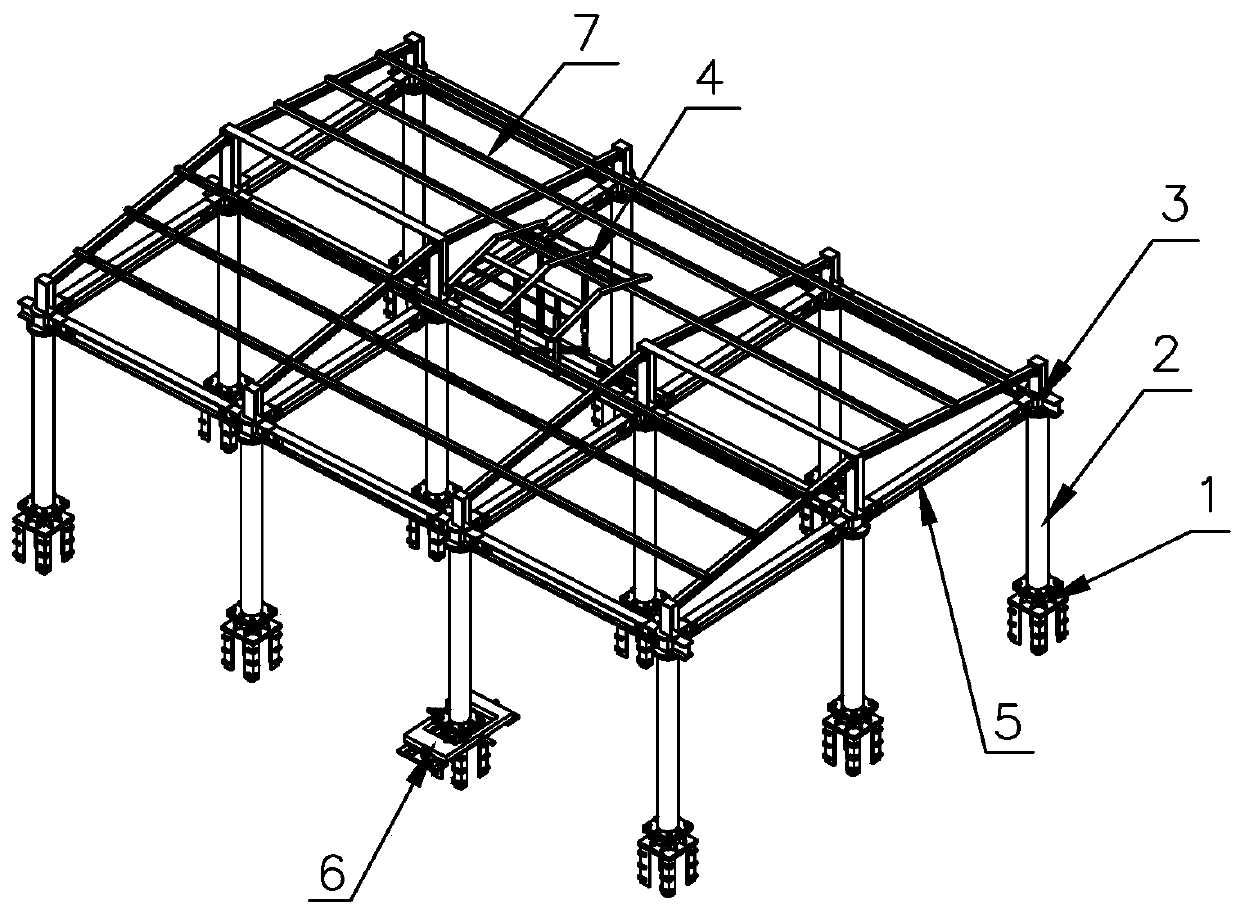

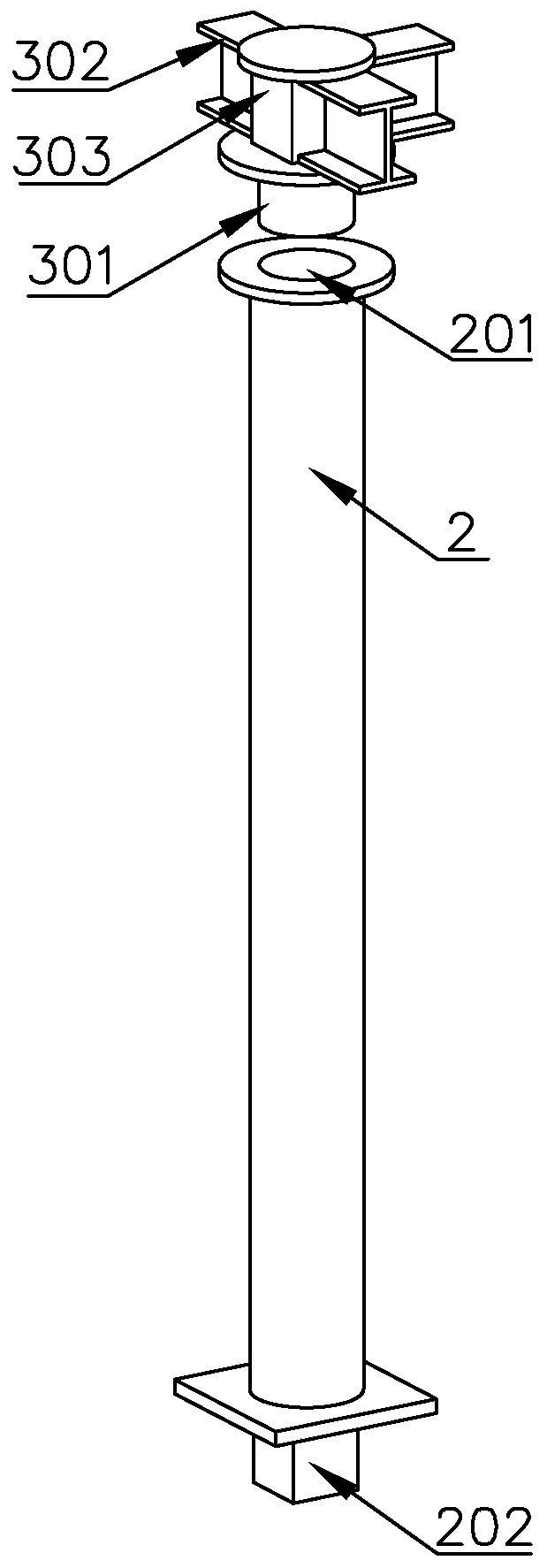

[0024] An extra-large steel structure supporting frame, including a pre-embedded base 1, a column 2, a steerable connection block 3, a liftable skylight 4, a beam 5, a leveling mechanism 6, and purlins 7, and the leveling mechanism 6 is set on the pre-embedded base 1, the pre-embedded base 1 is provided with a column 2, and the top of the column 2 is provided with a turnable connecting block 3, which is connected to the beam 5, and the liftable skylight 4 is set on the beam 5, and the steel structure beam frame is set There are 7 purlins.

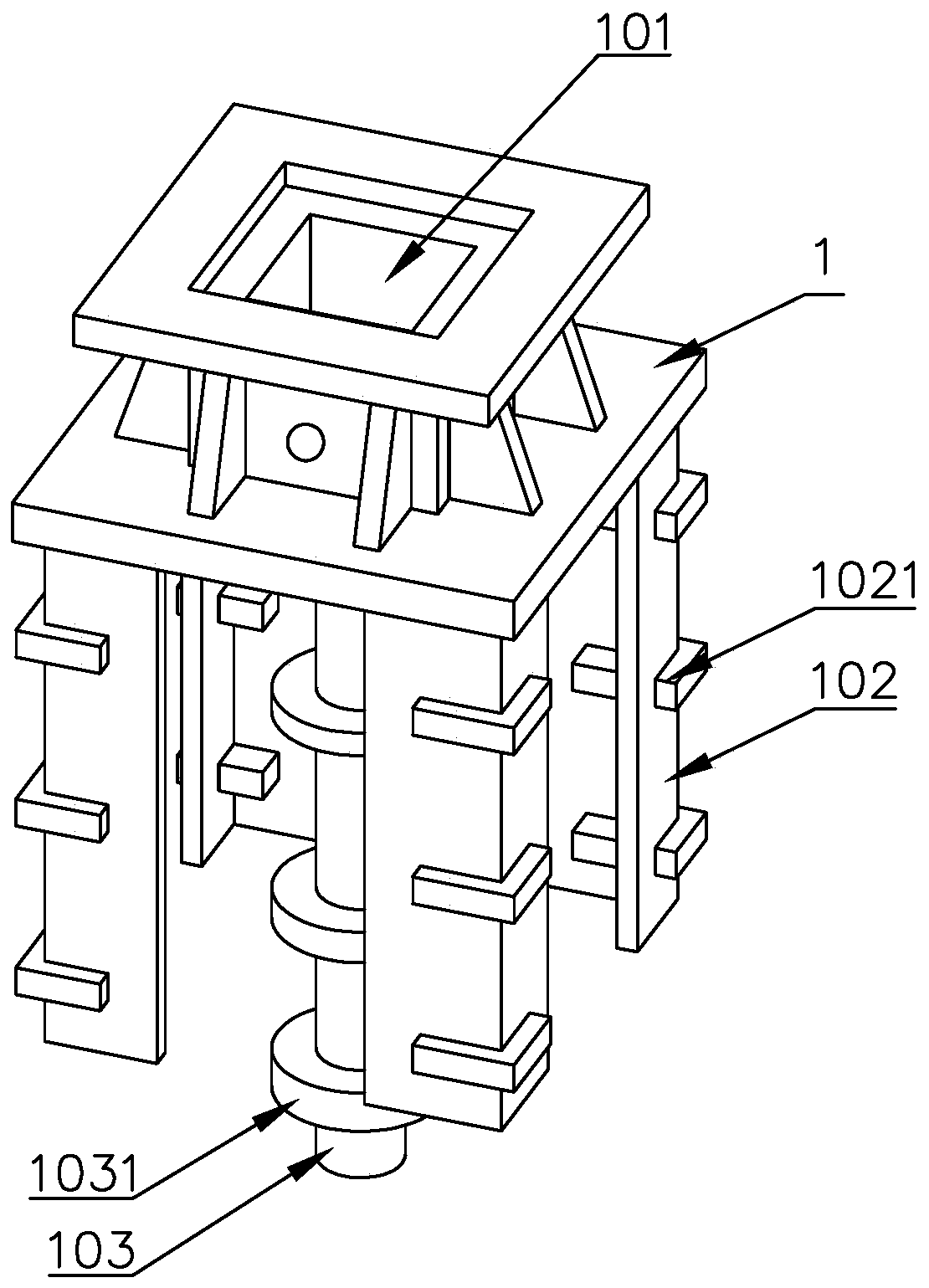

[0025] The embedded base 1 includes guide grooves 101, embedded columns I 102, and embedded columns II 103. The embedded base is provided with guide grooves 101, several embedded columns I 102 and embedded columns II 103.

[0026] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com