Connector and insertion core assembly thereof

A technology of components and ferrules, which is applied in the installation of connecting parts, parts of connecting devices, and connections, etc., can solve the problems of high labor intensity of workers, and it is not easy to determine the installation position of insulating pressure plates and insulators.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

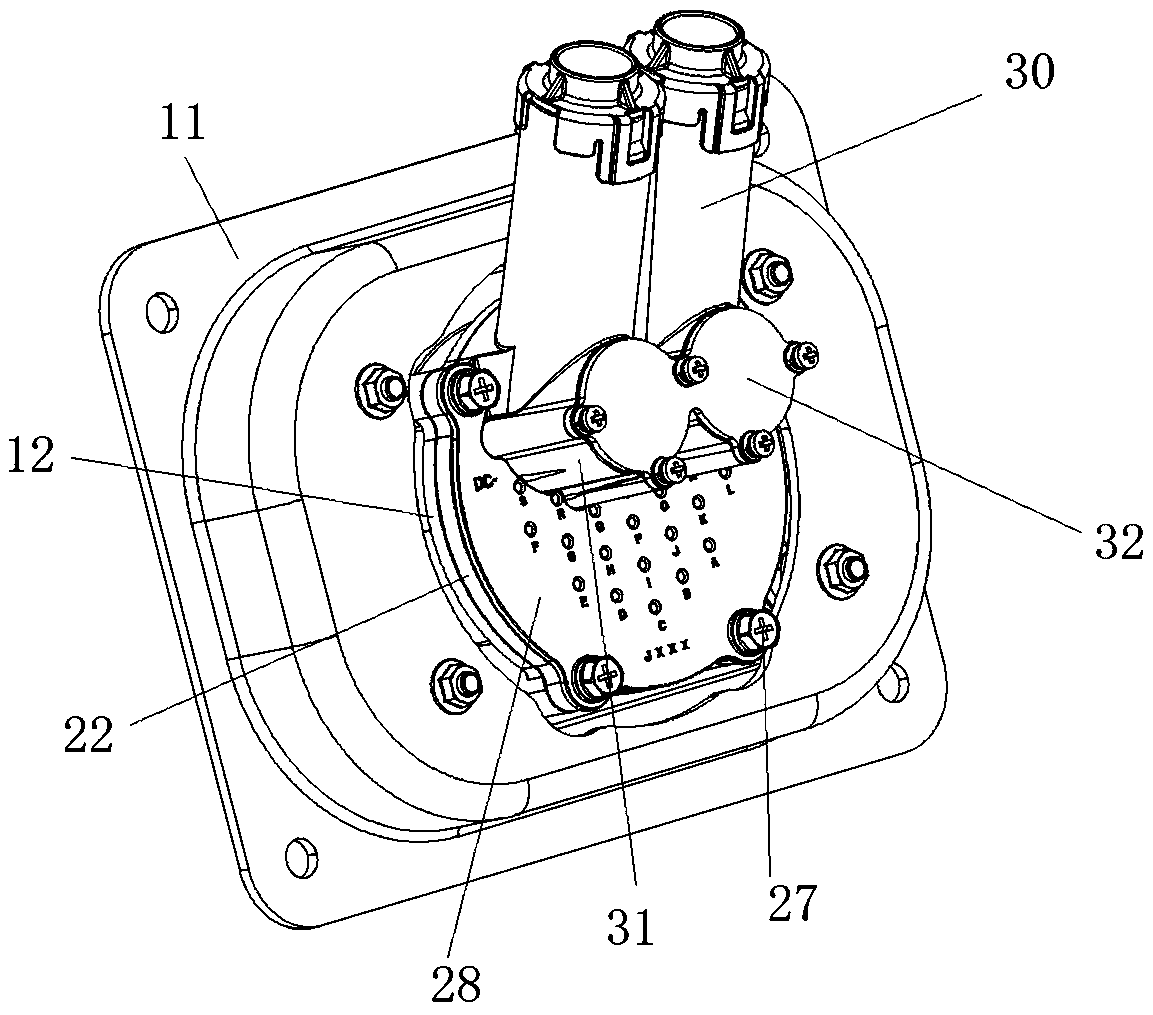

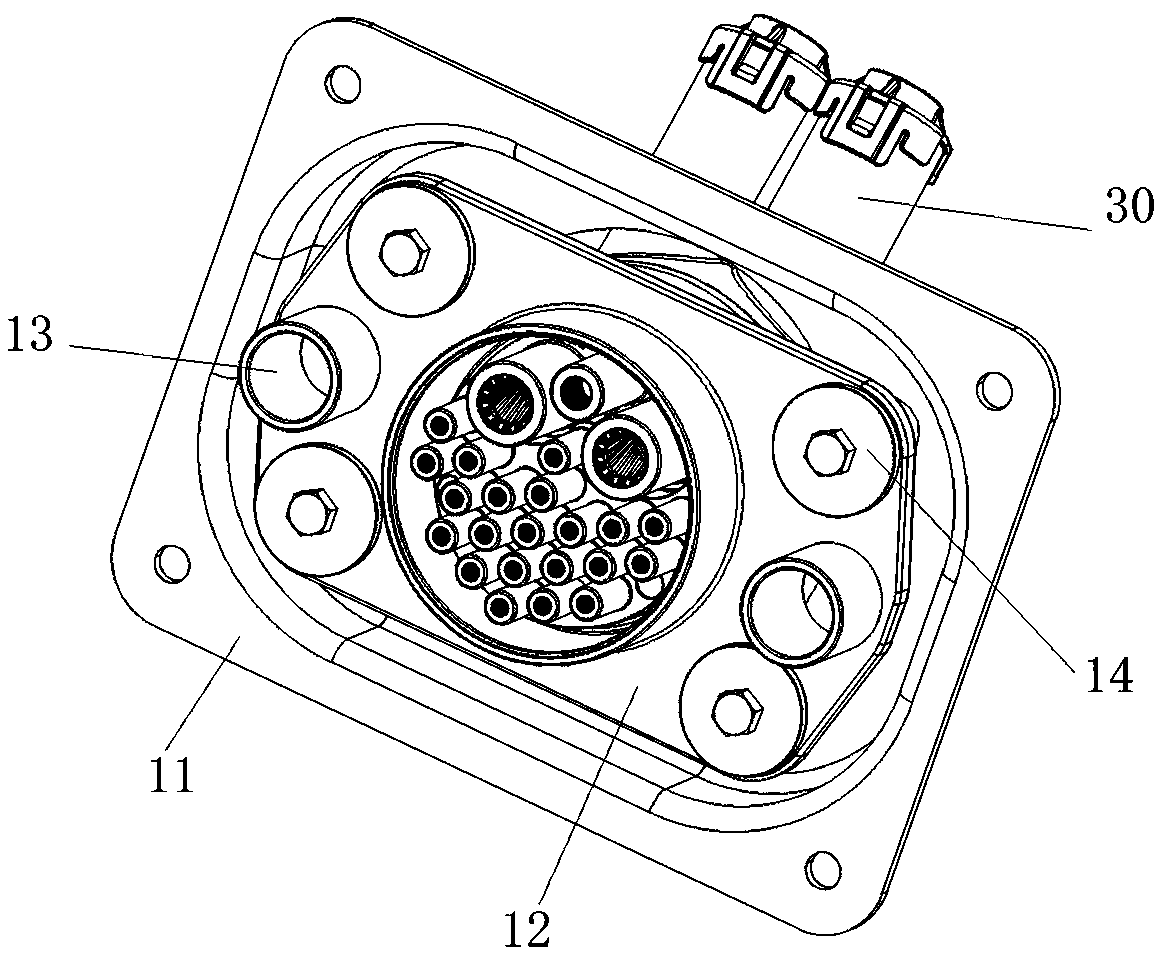

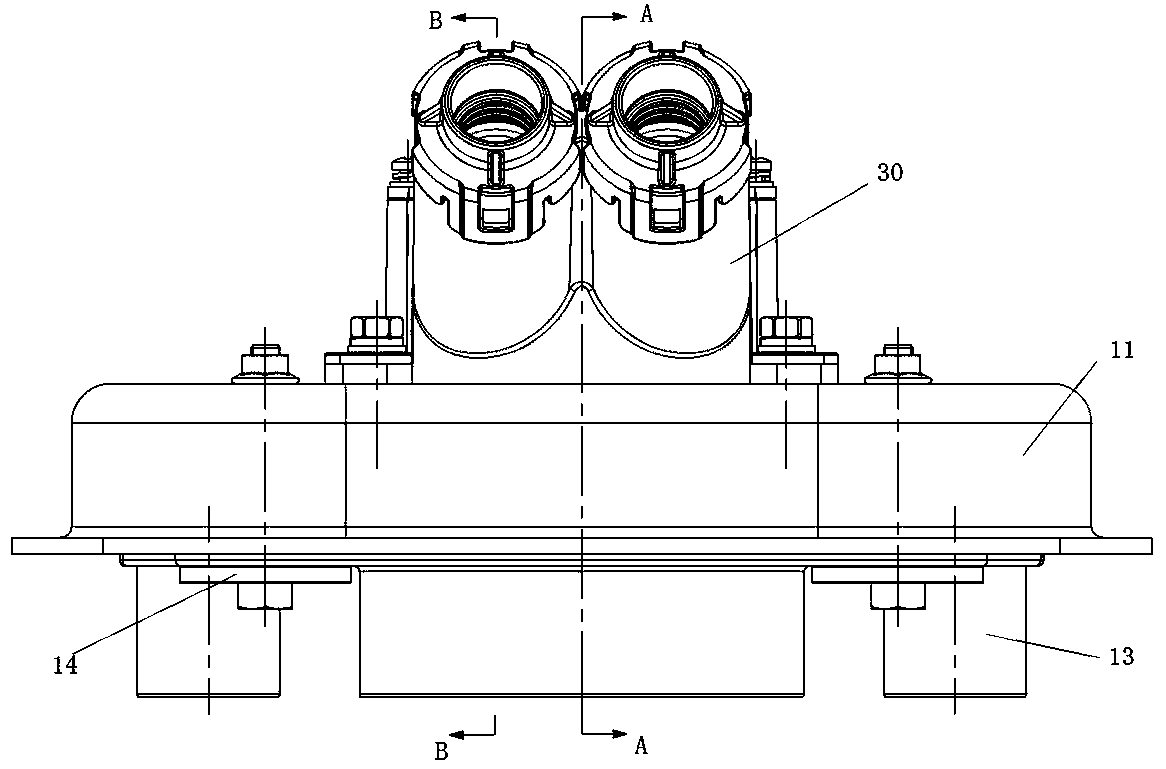

[0040] Specific embodiments of the connector of the present invention, such as Figure 1 to Figure 3 As shown, the connector includes a housing assembly 101, and the ferrule assembly 102 is fixedly installed in the housing assembly 101. The housing assembly 101 includes a fixed housing 11 and a floating housing 12, and the fixed housing 11 is used to fix and install the connector. On the installation panel, the floating housing 12 is floatingly fitted in the fixed housing 11 through the floating assembly 14, so as to ensure the normal plug-in of the connector and the reliability during plug-in. In other embodiments, the housing assembly may not float, and in this case, the connector may require multiple adjustments to be properly inserted when plugged.

[0041] Specifically, the floating assembly 14 includes a guide column, one end of the guide column i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com