Intelligent deposited ash sampling device and method for online measurement of effective thermal conductivity of deposited ash

A sampling device and thermal conductivity technology, which is applied in the field of intelligent ash sampling device for online measurement of the effective thermal conductivity of deposited ash, can solve the problems of single function, inability to realize real-time online monitoring of ash deposition thermal conductivity and intelligent cleaning control, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

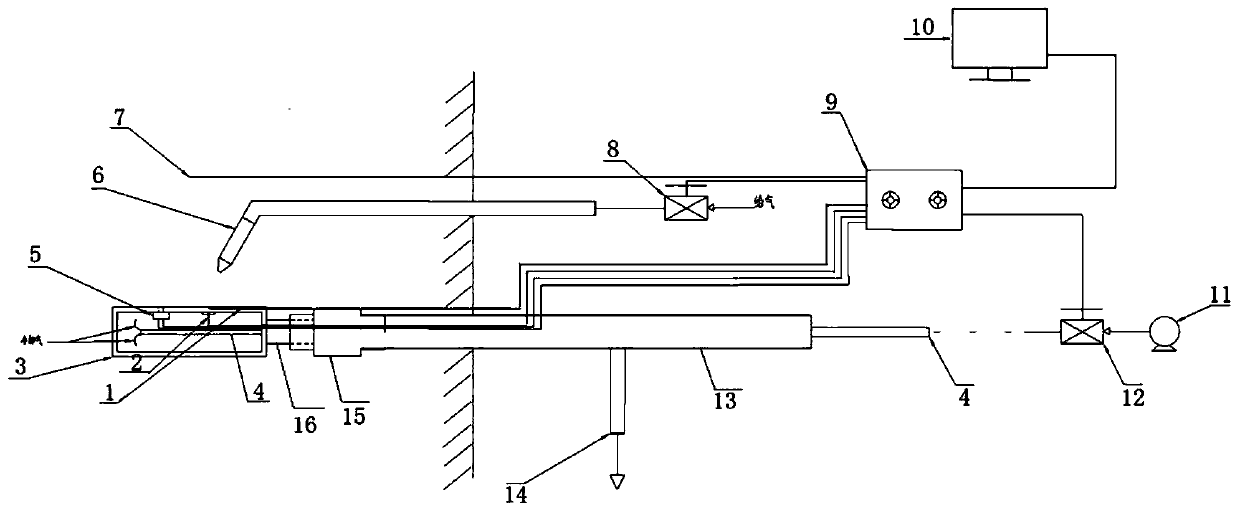

[0065] Such as figure 1 As shown, an intelligent ash sampling device for online measurement of the effective thermal conductivity of deposited ash in this embodiment includes a support outer sleeve 13, a sampling probe 3 connected to one end of the support outer sleeve 13, a temperature measurement unit, an intelligent Dust purge unit, probe outer wall temperature control unit, signal converter 9 and computer 10, wherein:

[0066] The sampling probe 3 is a tubular structure, one end of which is sealed, and the other end communicates with the outer casing 13 of the support body. The temperature measurement unit includes a first thermocouple 1, a second thermocouple 2 and a third thermocouple 7, wherein the first thermocouple 1 and the second thermocouple 2 are respectively installed on the outer surface and inner wall of the sampling probe 3, Its diameter is 1mm, and is respectively used for the temperature T of the outer wall and the inner wall of the sampling probe 3 1 , T ...

Embodiment 2

[0103] An intelligent ash sampling device for online measurement of the effective thermal conductivity of deposited ash in this embodiment, its structure is basically the same as in Embodiment 1, the main difference lies in: Specifically, in this embodiment, one end of the sampling probe 3 is fixed with a connection tube 16 , and its lumen communicates with the connecting tube 16 , and the other end of the connecting tube 16 is connected with the outer tube 13 of the support body through a straight-through ferrule 15 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com