An oil leakage prevention device for electro-hydraulic servo valve

An electro-hydraulic servo valve and anti-oil leakage technology, which is applied in the direction of servo motor components, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve problems such as waste of resources, pollution of the environment, and lack of anti-oil leakage design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

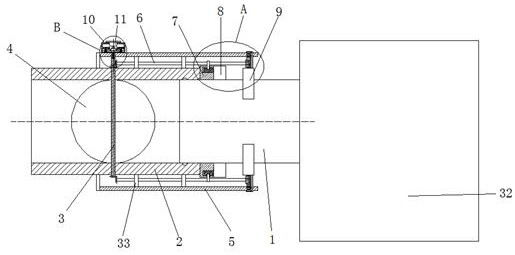

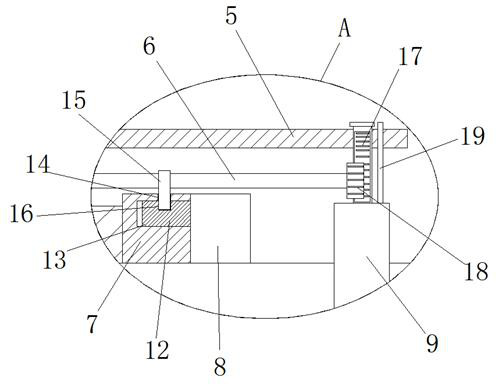

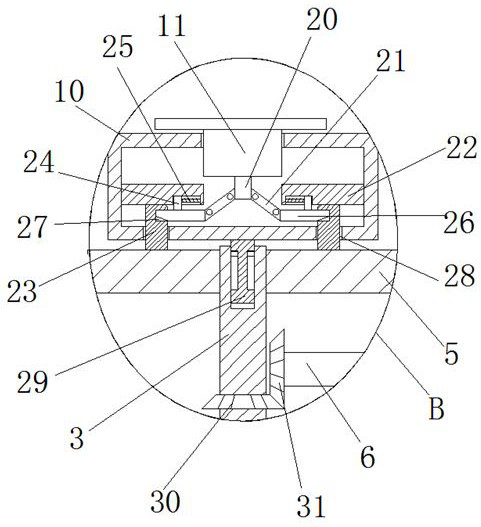

[0042] refer to Figure 1-7 , an oil leakage prevention device for an electro-hydraulic servo valve, comprising an electro-hydraulic servo valve 32, a connecting pipe 1 connected to the electro-hydraulic servo valve 32, a sealing pipe 2 movably connected to the connecting pipe 1, the inner wall of the sealing pipe 2 A plurality of sealing rings are arranged on the top, and the sealing rings are sealed and connected to the outside of the connecting pipe 1. Four welding rods 33 are arranged symmetrically on the outside of the sealing pipe 2, and the two welding rods 33 on the same horizontal axis are all fixed by welding. The same fixed bar 5 is installed, and a rack bar 17 is slidably installed on the two fixed bars 5, and one end of the two rack bars 17 that are close to each other is fixedly installed with an arc 9 by welding, and the two arcs 9 Both are matched with the connecting pipe 1, and two transverse shafts 6 are mounted on the outside of the sealing pipe 2 for symmet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com