Prefabricated wall preparation platform and wall unit made from the platform

A prefabricated and platform technology, applied in walls, buildings, building components, etc., can solve problems such as low construction efficiency, and achieve the effect of overcoming cold and hot bridges, improving pre-assembly efficiency, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

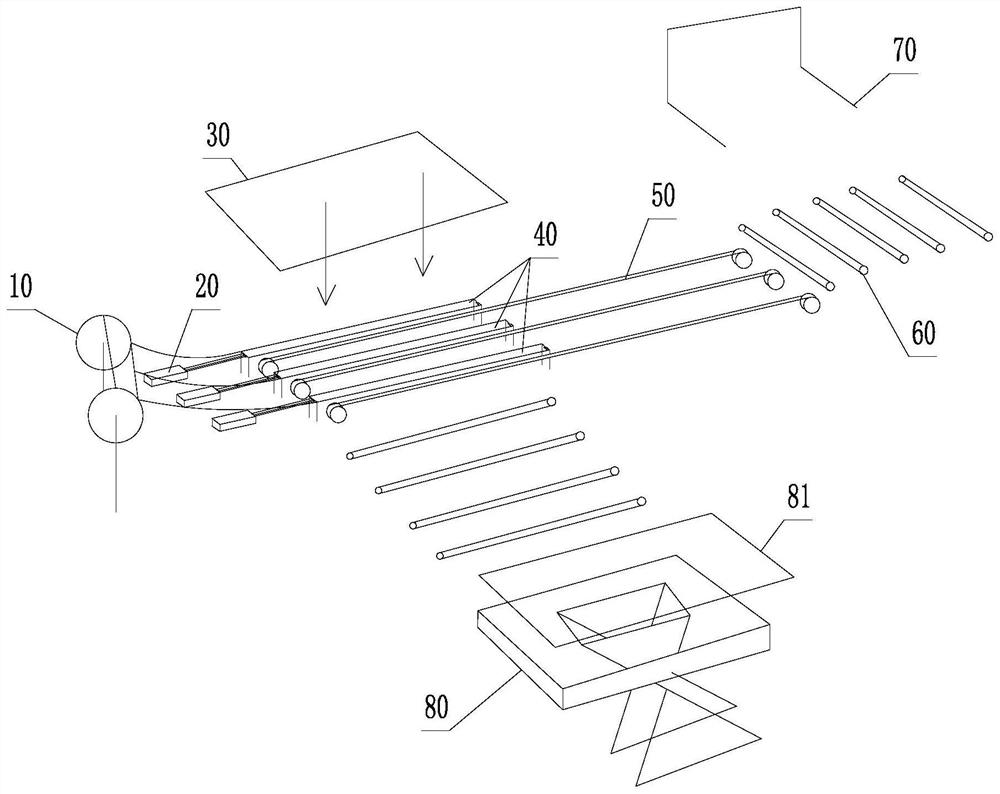

[0053] Such as figure 1 As shown, Embodiment 1 of the present invention provides a prefabricated wall preparation platform, including an assembly workbench 40, a keel unit 20 located on the first side of the assembly workbench 40, and a thermal insulation cotton unit 10 located on the second side of the assembly workbench 40. The plasterboard unit 80 on the side and the nailing unit 30 above the assembly workbench 40 .

[0054] In the specific operation, the thermal insulation cotton 11 output by the thermal insulation cotton unit 10 is located above the output keel 21 of the keel unit 20, the first side and the third side of the above-mentioned assembly workbench 40 are preferably arranged oppositely, and the second side is located on the second side. Between one side and the third side, that is, adjacent sides of the second side are respectively the first side and the third side.

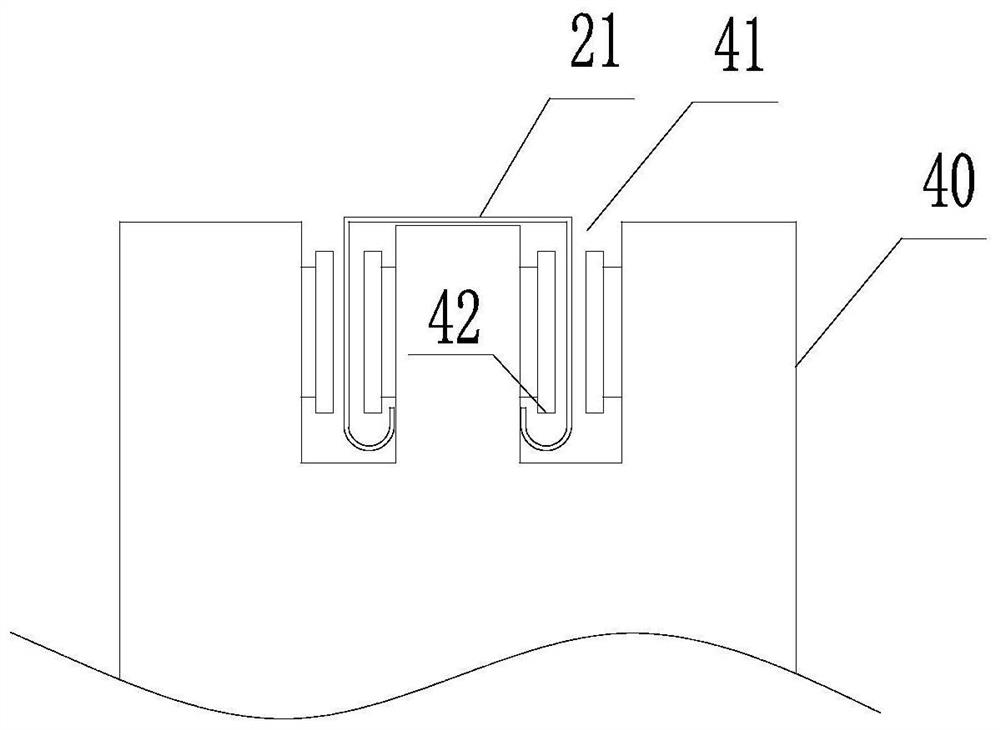

[0055]In this embodiment, the above-mentioned keel unit 20 includes a keel machine, and the k...

Embodiment 2

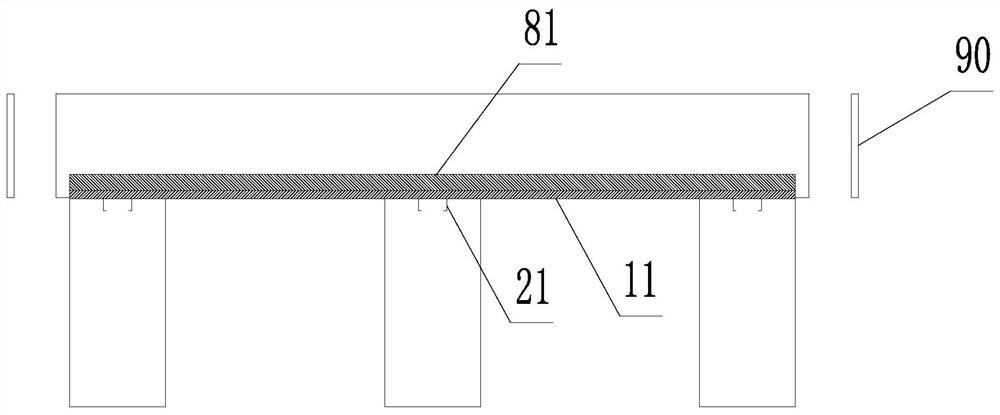

[0070] combine Figure 5 ~ Figure 15 As shown, Embodiment 2 of the present invention provides a thermal insulation integrated wall, including two wall units arranged on both sides of the two-way buckle 6 and connected by the two-way buckle 6; the wall unit includes gypsum board 81, thermal insulation cotton 11, vertically arranged keel 21 and horizontally arranged snap-in keel 2.

[0071] In this embodiment, the above-mentioned gypsum board 81 is fixed on the keel 21 by self-tapping screws 4, and the insulation cotton 11 is clamped between the gypsum board 81 and the keel 21; The snap-in keel 2 includes a plurality of clip joints evenly distributed, and the snap-in portions of the snap-in joist 2 fasten the bent edge of the connection keel 21 .

[0072] In the specific operation, the above-mentioned thermal insulation cotton 11 can realize the pre-assembly operation of the components before leaving the factory, that is, the corresponding pre-assembly operation of the gypsum b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com