Vacuum excavation head

A vacuum and material head technology, which is applied in earth movers/shovels, mechanically driven excavators/dredgers, construction, etc., can solve the problems of inconvenient, inconvenient, and labor-intensive operation of high-pressure water guns and excavation heads. Achieve the effects of avoiding high-pressure water jets from hurting people, easy to use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

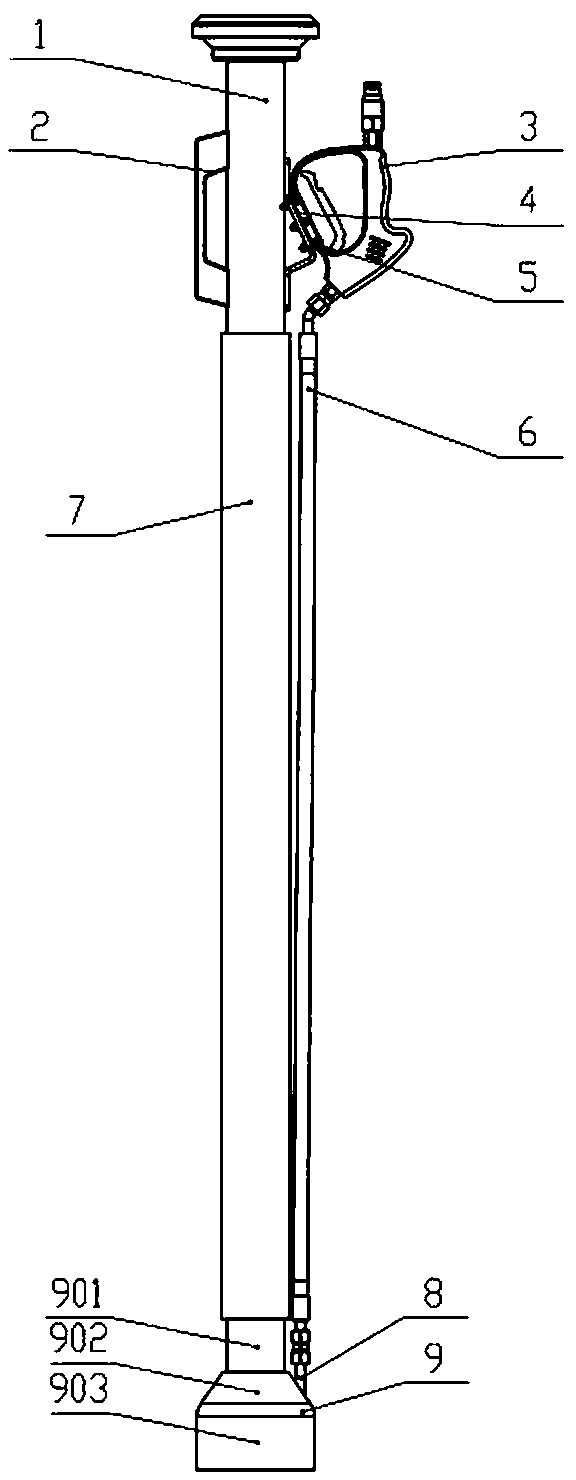

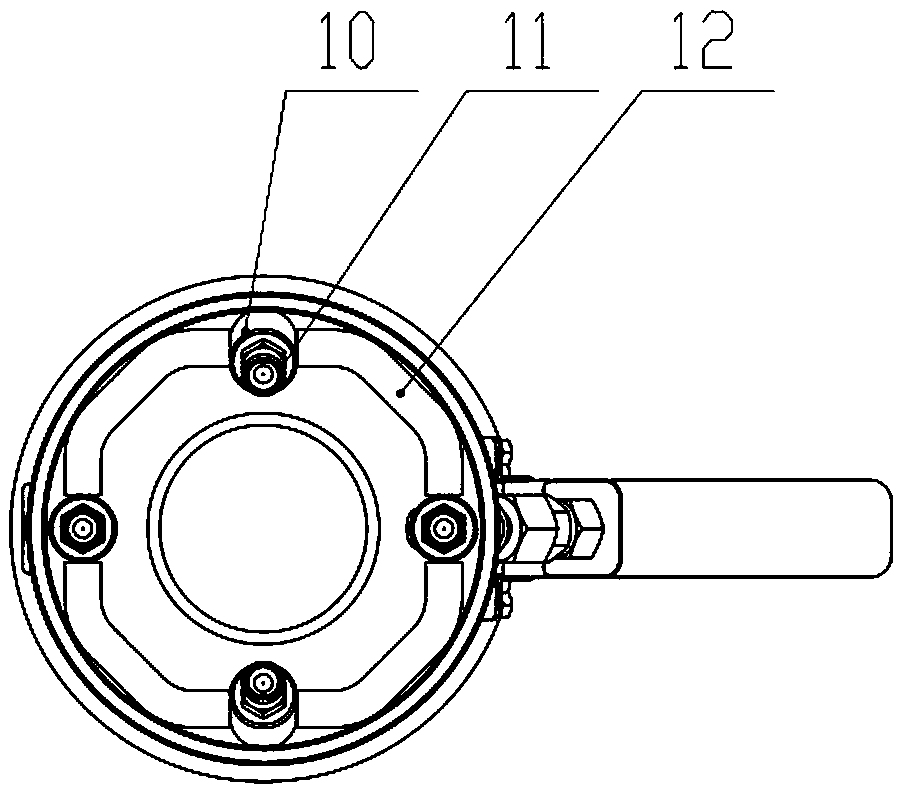

[0024] A vacuum excavation head, such as figure 1 and figure 2 As shown, it includes a connection joint 1, a high-pressure water gun 3, a water delivery hose 6, a suction pipe 7, a suction head 9, and a nozzle water supply channel. The connection joint 1 is welded to the upper end of the suction pipe 7 or connected by threads The suction head 9 is welded or fixed on the lower end of the suction pipe 7 through threaded connection, and also includes a pressure plate 4, the high-pressure water gun 3 is fixed on the connection joint 1 through the pressure plate 4, and the connection joint 1 is welded and fixed with a mounting seat , the pressure plate 4 is fixed on the mounting seat of the connecting joint 1 by connecting bolts 5 . The nozzle water supply passage communicates with the water delivery rubber hose 6 outside the suction head 9. A preset number of high-pressure nozzles 11 are installed on the nozzle water supply passage. The number of high-pressure nozzles 11 is 3-4....

Embodiment 2

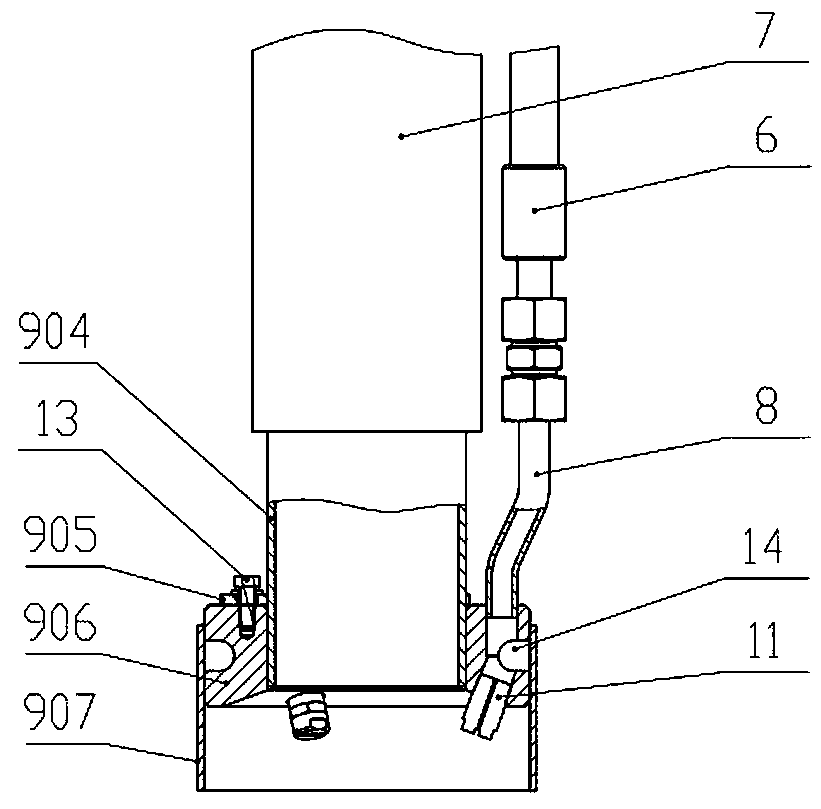

[0029] The difference between embodiment 2 and embodiment 1 is that the structure of suction head 9 is different, as image 3 As shown, the specific structure is as follows:

[0030]A vacuum excavation head, including a connection joint 1, a high-pressure water gun 3, a water delivery hose 6, a material suction pipe 7, a material suction head 9, and a nozzle water supply channel, and the connection joint 1 is welded to the upper end of the material suction pipe 7 or passed through Threaded connection, the suction head 9 is welded or fixed on the lower end of the suction pipe 7 by threaded connection, and also includes a pressure plate 4, the high-pressure water gun 3 is fixed on the connection joint 1 by the pressure plate 4, and the connection joint 1 is welded A mounting seat is fixed, and the pressing plate 4 is fixed on the mounting seat of the connecting joint 1 through connecting bolts 5 . The nozzle water supply passage communicates with the water delivery rubber hose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com