Sweeping mechanism with a variable sweeping plane disc for sweeping of road sweeper

A technology of road cleaning and cleaning mechanism, which is applied in the direction of road cleaning, cleaning methods, construction, etc. It can solve the problems of limited cleaning range, waste of time and resources, etc., and achieve the effect of increasing the area, reducing the use of motors, and ensuring stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

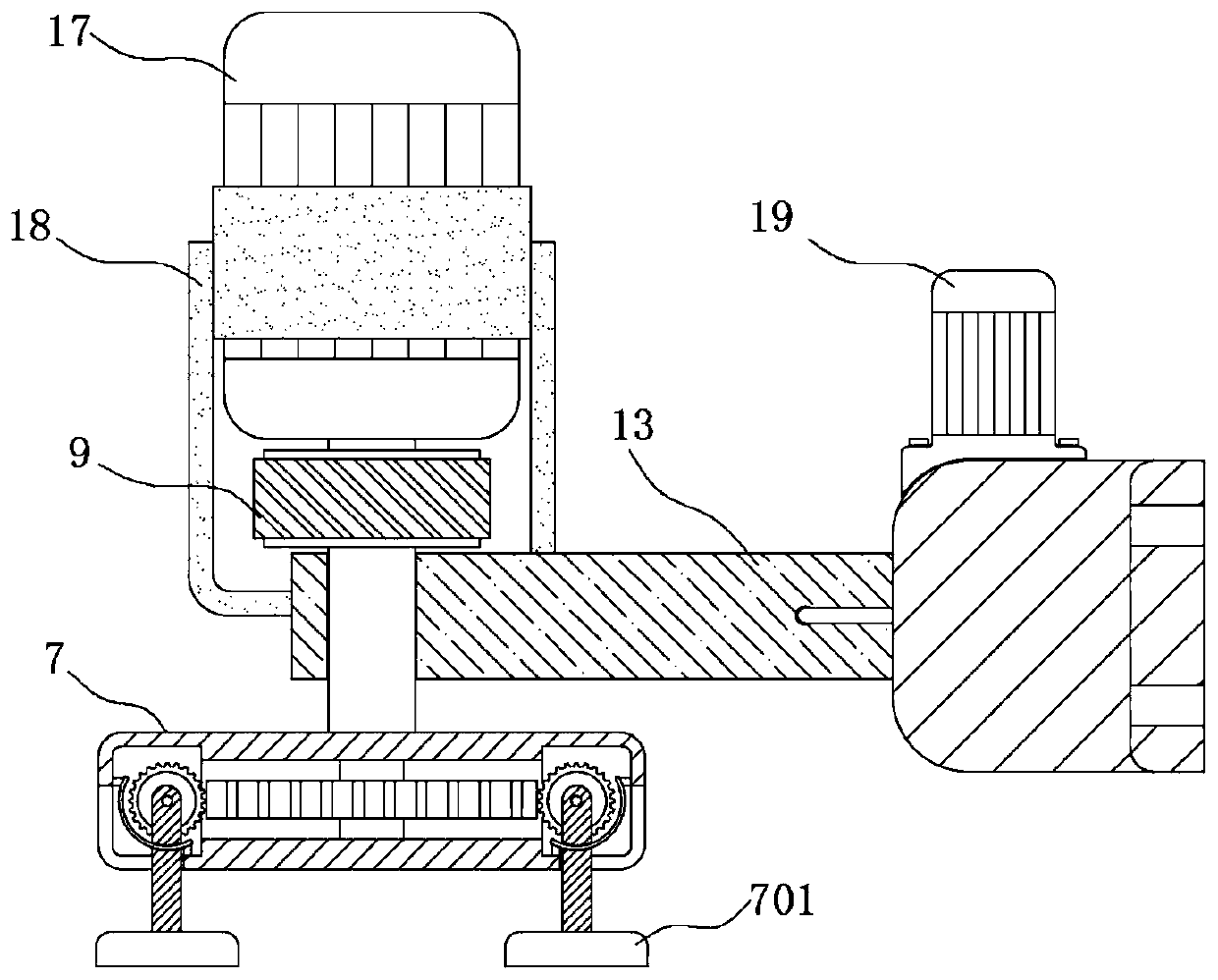

[0035] refer to Figure 1-4 , a cleaning mechanism of a road sweeping vehicle with a variable cleaning plane disk sweep, comprising a base 1, a plurality of threaded mounting holes 16 are symmetrically opened on the base 1, and a rack cavity 5 and a gear cavity 11 are opened in the base 1 , and the rack chamber 5 communicates with the gear chamber 11, the rack chamber 5 is slidingly connected with a rack 3, the inner top wall of the rack chamber 5 is provided with a chute 2, and the upper end of the rack 3 is symmetrically fixedly connected with a plurality of slider 4, and each slider 4 is slidably connected in the chute 2, the first motor 19 is installed on the side wall of the base 1, the output shaft of the first motor 19 extends into the gear chamber 11 and is installed with a drive Wheel 12, and driving wheel 12 meshes with rack 3.

[0036] A plurality of grooves 15 are symmetrically opened on the base 1, and each groove 15 is in communication with the rack cavity 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com