Degradable film and preparation method thereof

A technology for degrading films and containers, applied in the field of degradable films and preparation, can solve problems such as easy water loss, shortened service life, and film drying, and achieve the effects of avoiding unfavorable factors, reducing the number of bubbles, and improving tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

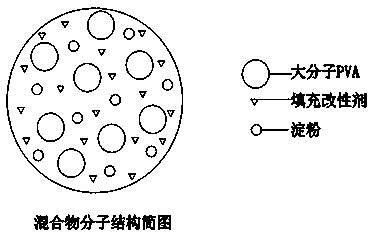

[0026] The method for preparing a small amount of PVA degradable film in the laboratory is as follows, formula; PVA 100g, corn starch 40g, glycerin 40g, crosslinking agent PLA 5g, filling modifier sugarcane fiber 10g and purified water 1700g.

[0027] Among them, PVA and the cross-linking agent PLA have good mutual solubility, and both have a degradation effect, glycerin has a plasticizing effect, starch and filling modifier sugarcane fiber have a filling effect, and make them have good biocompatibility .

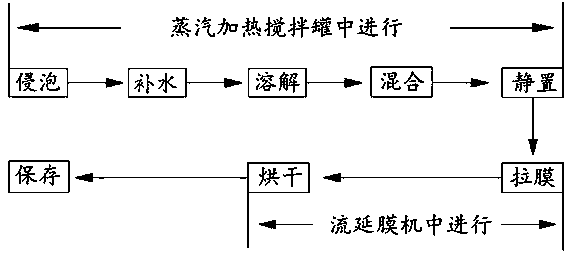

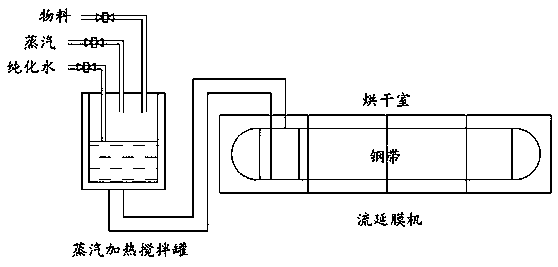

[0028] A method for preparing a small amount of PVA degradable film in the laboratory, such as figure 1 with figure 2 shown, including the following steps:

[0029] A. Soaking: Add 100g of PVA and 1000g of purified water into a 5L steam-heated stirring tank and stir evenly, let it stand for 12 hours before use; add 40g of cornstarch and 400g of purified water into a container 1 with a volume of 1L, and soak for 4 hours for use Add glycerin 40g, cross-linking agent PLA5g...

Embodiment 2

[0052] The working principle of embodiment 2 is the same as that of embodiment 1.

[0053] Implementation column 3

[0054] A degradable film, each component by weight percentage: PVA 50%, corn starch 20%, glycerin 20%, crosslinking agent PLA 2.5%, filler modifier 20% sugarcane fiber and purified water 870%.

[0055] Among them, PVA and the cross-linking agent PLA have good mutual solubility, and both have a degradation effect, glycerin has a plasticizing effect, starch and filling modifier sugarcane fiber have a filling effect, and make them have good biocompatibility .

[0056] Such as figure 1 with figure 2 Shown, a kind of preparation method of degradable film comprises the following steps:

[0057] A. Soaking: Add 50% PVA and 500% purified water into the steam heating mixing tank and stir evenly, and then set aside for use after standing for 12 hours; add 20% corn starch and 200% purified water into container 1, and soak for 4 hours for later use; In 2, add 20% glyc...

Embodiment 3

[0065] The working principle of embodiment 3 is the same as that of embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com