Garbage percolate treatment process

A landfill leachate and treatment process technology, applied in the field of landfill leachate treatment process, can solve the problems of reduced biodegradability, consumption of biodegradable substances, and infeasibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

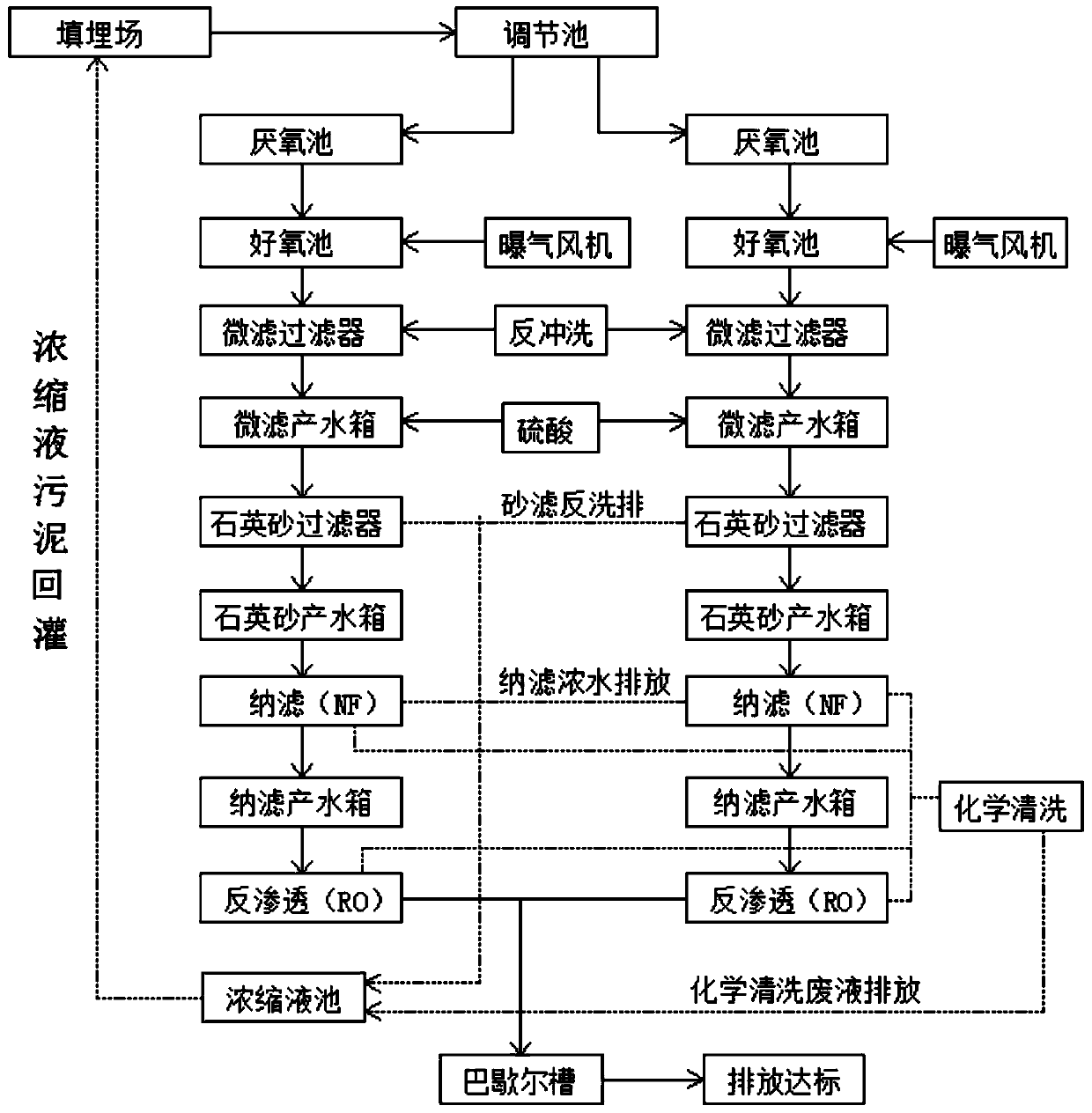

[0023] A landfill leachate treatment process, comprising the following steps:

[0024] Step 1. The landfill leachate is settled and separated through the adjustment tank, and the water quality is homogenized and the water volume is adjusted at the same time;

[0025] Step 2. The landfill leachate regulated by the regulating tank is put into the anaerobic pool, and the macromolecular refractory organic matter in the landfill leachate is decomposed into easily degradable organic matter through anaerobic metabolism of microorganisms;

[0026] Step 3. Put the landfill leachate after anaerobic treatment into the aerobic pool, and oxidize and decompose it for metabolism through the action of highly active aerobic microorganisms;

[0027] Step 4. After aerobic treatment, use a microfiltration filter to pump the landfill leachate into the microfiltration filter, and then enter the microfiltration water production tank for filtration;

[0028] Step 5. After the filtration in the micro...

Embodiment 2

[0032] The specific method and detection of this embodiment are the same as in Example 1, only the operating parameters are changed as follows: the operating pressure of reverse osmosis is 7.5MPa, and the intercepted component is 7×10 -10 mSmall molecule solutes.

Embodiment 3

[0034] The specific method and detection of this embodiment are the same as in Example 1, only the operating parameters are changed as follows: the operating pressure of reverse osmosis is 3.5MPa, and the intercepted component is 4×10 -10 mSmall molecule solutes.

[0035] After being treated by this method, the still water is sent to the physical and chemical testing center for testing, and the testing results are compared with my country's landfill leachate discharge standard (GB16889-2008) to obtain the following data:

[0036] Pollutants 2008 Standard Emission Limits Example 1 Example 2 Example 3 Compared SS(mg / L) 30 not detected not detected not detected excellent BOD 5 (mg / L)

[0037] From the above data, it can be known that the purified water obtained by using this method to treat landfill leachate is better than my country's landfill leachate discharge standard (GB16889-2008).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com